Abstract

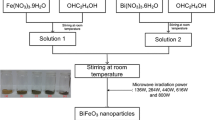

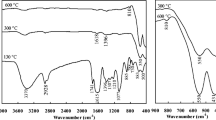

Bismuth ferrite (BiFeO3) acting as a significant multiferroic material exhibits unique magnetic and ferroelectric properties. Here we report the size-controlled synthesis of BiFeO3 nanoparticles via a facile and stable Pechini sol–gel method, in which uses tartaric acid as a complexing agent, ethylene glycol as a polymerizing agent. It is found that the nanoparticle size is sensitive to the gel-forming temperature. The nanoparticles with size as small as 30 nm have been obtained. A sequential reaction process and the mechanism of size controllable growth of BiFeO3 has been presented. The effects of size on optical and magnetic properties have been also investigated. The decreasing particles lead to blue shift in the band gap. BiFeO3 nanoparticles show weak ferromagnetic character due to a Fe3+ oxidation state, and the magnetization increases with decrease in the particle size.

Similar content being viewed by others

References

J. Wang, J.B. Neaton, H. Zheng, V. Nagarajan, S.B. Ogale, B. Liu, D. Viehland, V. Vaithyanathan, D.G. Schlom, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, M. Wuttig, R. Ramesh, Science 299, 1719–1722 (2003)

F. Gao, X.Y. Chen, K.B. Yin, S. Dong, Z.F. Ren, F. Yuan, T. Yu, Z.G. Zou, J.M. Liu, Adv. Mater. 19, 2889–2892 (2007)

N. Ortega, A. Kumar, J.F. Scott, R.S. Katiyar, J. Phys. Condens. Matter 27, 504002 (2015)

M. Tokunaga, M. Akaki, T. Ito, S. Miyahara, A. Miyake, H. Kuwahara, N. Furukawa, Nat. Commun. 6, 5878 (2015)

Y. Wang, Q.-H. Jiang, H.-C. He, C.-W. Nan, Nat. Commun. 6, 142503 (2006)

S.M. Selbach, T. Tybell, M.-A. Einarsrud, T. Grande, Adv. Mater. 20, 3692–3696 (2008)

S. Sharma, V. Singh, R.K. Kotnala, R.K. Dwivedi, J. Mater. Sci. Mater. Electron. 25, 1915–1921 (2014)

J.G. Wu, J. Wang, Acta Mater. 58, 1688–1697 (2013)

S.R. Basu, L.W. Martin, Y.H. Chu, M. Gajek, R. Ramesh, R.C. Rai, X. Xu, J.L. Musfeldt, Appl. Phys. Lett. 92, 091905 (2008)

J.G. Wu, S. Qiao, J. Wang, D.Q. Xiao, J.G. Zhu, Appl. Phys. Lett. 102, 052904 (2013)

F. Gao, Y. Yuan, K.F. Wang, X.Y. Chen, F. Chen, J.M. Liu, Z.F. Ren, Appl. Phys. Lett. 89, 102506 (2006)

K. Takahashi, N. Kida, M. Tonouchi, Phys. Rev. Lett. 96, 117402 (2006)

J.M. Wesselinowa, I. Apostolova, J. Appl. Phys. 104, 084108 (2008)

S. Zhang, L. Wang, Z. Gao, X. Zhang, D. Wang, Y. Ma, Mater. Lett. 65, 3309–3312 (2011)

M. Escobar Castillo, V.V. Shvartsman, D. Gobeljic, Y. Gao, J. Landers, H. Wende, D.C. Lupascu, Nanotechnology 24, 355701 (2013)

T.P. Gujar, V.R. Shinde, C.D. Lokhande, Mater. Chem. Phys. 103, 142–146 (2007)

H. Yang, T. Xian, Z.Q. Wei, J.F. Dai, J.L. Jiang, W.J. Feng, J. Sol-Gel. Sci. Technol. 58, 238–243 (2010)

C. Chen, J. Cheng, S. Yu, L. Che, Z. Meng, J. Cryst. Growth 291, 135–139 (2006)

N. Das, R. Majumdar, A. Sen, H.S. Maiti, Mater. Lett. 61, 2100–2104 (2007)

S. Farhadi, M. Zaidi, J. Mol. Catal. A Chem. 299, 18–25 (2009)

S. Ghosh, S. Dasgupta, A. Sen, H.S. Maiti, Mater. Res. Bull. 40, 2073–2079 (2005)

P. Sharma, V. Verma, J. Magn. Magn. Mater. 374, 18–21 (2015)

Y. Wang, G. Xu, L. Yang, Z. Ren, X. Wei, W. Weng, P. Du, G. Shen, G. Han, Ceram. Int. 35, 1285–1287 (2009)

A. Chaudhuri, S. Mitra, M. Mandal, K. Mandal, J. Alloys Compd. 491, 703–706 (2010)

E. Coronado, J.R. Galan-Mascaros, C.J. Gomez-Garcia, A. Murcia-Martinez, Chem. Eur. J. 12, 3484–3492 (2006)

K. Chakrabarti, K. Das, B. Sarkar, S.K. De, J. Appl. Phys. 110, 103905 (2011)

T.D. Kang, H. Lee, S.J. Park, J. Jang, S. Lee, J. Appl. Phys. 92, 2467 (2002)

G.S. Lotey, N.K. Verma, J. Nanopart. Res. 13, 5397–5405 (2011)

G.S. Lotey, N.K. Verma, Chem. Phys. Lett. 574, 71–77 (2013)

B. Ramachandran, A. Dixit, R. Naik, G. Lawes, M.S.R. Rao, Phys. Rev. B 82, 012102 (2010)

Y.B. Li, T. Sritharan, S. Zhang, X.D. He, Y. Liu, Appl. Phys. Lett. 92, 132908 (2008)

S. Goswami, D. Bhattacharya, P. Choudhury, J. Appl. Phys. 109, 07D737 (2011)

Acknowledgments

This work is supported by the Natural Science Foundation of China (Nos. 11474199 and 51332009). School of Materials Science and Engineering, Shanghai Jiaotong University and National Engineering Research Center for Nanotechnology are gratefully acknowledged for assisting relevant analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, B., Guo, Y., Pan, D. et al. Size-controlled synthesis of BiFeO3 nanoparticles by a facile and stable sol–gel method. J Mater Sci: Mater Electron 27, 10803–10809 (2016). https://doi.org/10.1007/s10854-016-5186-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5186-x