Abstract

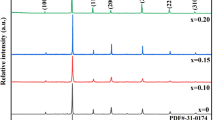

Ba(Zr x Ti1−x )O3 ceramics are prepared via the conventional solid state reaction method. The Zr4+ ions have diffused into the BaTiO3 lattices to form a homogenous solid solution. The effects of Zr/Ti ratio on dielectric properties and breakdown strength of Ba(Zr x Ti1−x )O3 ceramics are systematically discussed. The high porosities of Ba(Zr x Ti1−x )O3 ceramics deteriorate seriously the dielectric constant, dielectric loss and the breakdown strength. When the concentration of Zr4+ ions increase from x = 0.05 to x = 0.20, the Curie temperature Tc decreases slightly from 120 to 60 °C, the grain sizes decrease slightly as well attributing to the difference ionic radius of Ti4+ ions and Zr4+ ions. The concentration of Zr4+ ions has a significant effect on the breakdown strength of Ba(Zr x Ti1−x )O3 ceramics. Excellent breakdown strength and dielectric properties are achieved in the BaZr0.15Ti0.85O3 ceramics sintered at 1260 °C for 2 h: Eb = 12.028 kv/mm, ε r = 3334.6, tanδ = 0.005.

Similar content being viewed by others

References

J.Q. Qi, B.B. Liu, H.Y. Tian, H. Zou, Z.X. Yue, L.T. Li, Solid State Sci. 14, 1520 (2012)

P. Zheng, K.X. Song, H.B. Qin, L. Zheng, L.M. Zheng, Curr. Appl. Phys. 13, 1064 (2013)

J.I. Yang, R.G. Polcawich, L.M. Sanchez, S. Trolier-McKinstry, J. Appl. Phys. 117, 014103 (2015)

Y.J. Eoh, E.S. Kim, Ceram. Int. 41, S2 (2015)

W.Q. Cao, J.W. Xiong, J.P. Sun, Mater. Chem. Phys. 1063, 38 (2007)

H.W. Chen, C.R. Yang, C.L. Fu, J. Shi, J.H. Zhang, W.J. Leng, J. Mater. Sci. Mater. Electron. 19, 379 (2007)

A. Zeb, S.J. Milne, J. Mater. Sci. Mater. Electron. 26, 9243 (2015)

T. Tsurumi, Y. Yamamoto, H. Kakemoto, S. Wada, J. Mater. Res. 17, 755 (2002)

W.S. Choi, B.S. Jang, D.G. Lim, J.S. Yi, B.Y.Y. Hong, J. Cryst. Growth 237–239, 438 (2002)

W. Cai, C.L. Fu, J.C. Gao, X.L. Deng, J. Mater. Sci. Mater. Electron. 21, 317 (2009)

W.S. Choi, J.H. Boo, J.S. Yi, B.Y.Y. Hong, Mater. Sci. Semicond. Process. 2, 211 (2003)

D.Y. Liang, X.H. Zhu, J.L. Zhu, J.G. Zhu, D.Q. Xiao, Ceram. Int. 40, 2585 (2014)

S.J. Kuang, X.G. Tang, L.Y. Li, Y.P. Jiang, Q.X. Liu, Scr. Mater. 61, 68 (2009)

M.H. Kallel, I. Kriaa, H.M.D. Khemakhem, Ceram. Int. 42, 1379 (2016)

Y.L. Wang, L.T. Li, J.Q. Qi, Z.L. Gui, Ceram. Int. 28, 657 (2002)

N. Ding, X.G. Tang, X.D. Ding, Q.X. Liu, Y.P. Jiang, L.L. Jiang, J. Mater. Sci. Mater. Electron. 25, 2305 (2014)

D. Shan, Y.F. Qu, J.J. Song, Solid State Commun. 141, 65 (2007)

Y.L. Li, R.R. Wang, X.G. Ma, Z.Q. Li, R.L. Sang, Y.F. Qu, Mater. Res. Bull. 44, 6143 (2005)

Z.Y. Shen, Q.G. Hu, Y.M. Li, Z.M. Wang, W.Q. Luo, Y. Hong, Z.X. Xie, R.H. Liao, J. Am. Ceram. Soc. 96, 2551 (2013)

A. Young, G. Hilmas, S.C. Zhang, R.W. Schwartz, J. Am. Ceram. Soc. 90, 1504 (2007)

Y. Yang, S. C. Zhang, F. Dogan, E. Schamiloglu, J. Gaudet, Influence of Nanocrystalline Grain Size on the Breakdown Strength of Ceramic Dielectrics, vol. 1 (IEEE International Pulsed Power Conference, 2003), p. 722

V.S. Puli, A. Kumar, R.S. Katiyar, X. Su, C.M. Busta, D.B. Chrisey, M. Tomozawa, J. Non-Cryst. Solids 358, 3510 (2012)

X.G. Wang, Y. Zhang, X.Z. Song, Z.B. Yuan, T. Ma, Q. Zhang, C.S. Deng, T.X. Liang, J. Eur. Ceram. Soc. 32, 559 (2012)

D.A. Tuan, V.T. Tung, T.V. Chuong, Int. J. Mod. Phys. B 29, 1550231 (2015)

X.G. Huang, J. Zhang, W.F. Rao, T.Y. Sang, B. Song, C.P. Wong, J. Alloys. Compd. 662, 409 (2016)

X.G. Huang, Y.Y. Chen, J.H. Yu, J. Zhang, T.Y. Sang, G.X. Tao, H.L. Zhu, J. Mater. Sci. Mater. Electron. 26, 3474 (2015)

Acknowledgments

This work is supported by Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), the Opening Project of State Key Laboratory of High Performance Ceramics and Superfine Microstructure (Project No. SKL201309SIC), as well as Science and Technology Projects of Guangdong Province (Project No. 2011A091103002). This work is partly supported by National Natural Science Foundation of China (51502132).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Li, Y., Zhu, H. et al. Influence of Zr/Ti ratio on the dielectric properties of BaZr x Ti1−x O3 ceramics for high-voltage capacitor applications. J Mater Sci: Mater Electron 27, 9572–9576 (2016). https://doi.org/10.1007/s10854-016-5010-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5010-7