Abstract

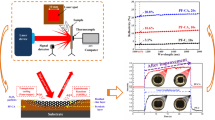

In this paper, the aluminum/polymer composite coating was prepared and the infrared emitting properties and environmental stability performance of the as-prepared coating were studied. The factors, such as polymer binders, pigment/binder ratios, preparation technology and coating thickness were investigated in detail. Firstly, the study of the polymer binders indicated that modified fluorocarbon resin was the best candidate due to its low infrared emissivity and well-performed physical and chemical properties. Secondly, the optimal pigment/binder ratio was 1.25:1. Thirdly, the optimum coating thickness was 75 μm and the scrape coating method was suitable to prepare the coating. Finally, the optimized aluminum/polymer composite coating showed low infrared emissivity of 0.31. The adhesive force of the coating was first grade and the impact resistance was more than 50 kg cm. In addition, it exhibited excellent salt, acid and alkali resistance. The as-prepared aluminum/polymer composite coating can be used as infrared stealth coating in the wavelength of 8–14 μm.

Similar content being viewed by others

References

X.G. Huang, J. Zhang, W. Wang, T.Y. Sang, B. Song, H.L. Zhu, W.F. Rao, C.P. Wong, J. Magn. Magn. Mater. 405, 36–41 (2016)

X.G. Huang, J. Zhang, W.F. Rao, T.Y. Sang, B. Song, C.P. Wong, J. Alloy. Compd. 662, 409–414 (2016)

X.G. Huang, J. Zhang, Z.H. Liu, T.Y. Sang, B. Song, H.L. Zhu, C.P. Wong, J. Alloy. Compd. 648, 1072–1075 (2015)

C.C. Yang, Y.J. Gung, W.C. Hung, T.H. Ting, K.H. Wu, Compos. Sci. Technol. 70, 466–471 (2010)

H. Yu, G. Xu, X. Shen, X. Yan, C. Cheng, Appl. Surf. Sci. 255, 6077–6081 (2009)

X.F. Liu, Y.K. Lai, J.Y. Huang, S.S. Al-Deyab, K.Q. Zhang, J. Mater. Chem. C 3, 345–351 (2015)

P.K. Biswas, A. De, N.C. Pramanik, P.K. Chakraborty, K. Ortner, V. Hock, S. Korder, Mater. Lett. 57, 2326–2332 (2003)

D.P. Sheehan, Entropy 14, 1915–1938 (2012)

W. Zhang, G. Xu, R. Ding, K. Duan, J. Qiao, Mater. Sci. Eng., C 33, 99–102 (2013)

W.G. Zhang, G.Y. Xu, J.C. Zhang, H.H. Wang, H.L. Hou, Opt. Mater. 37, 343–346 (2014)

S.J. Fang, W. Wang, X.L. Yu, H. Xu, Y. Zhong, X.F. Sui, L.P. Zhang, Z.P. Mao, Mater. Lett. 143, 120–123 (2015)

Z.P. Mao, W. Wang, Y. Liu, L.P. Zhang, H. Xu, Y. Zhong, Thin Solid Films 558, 208–214 (2014)

Y. Yang, Y.M. Zhou, J.H. Ge, X.M. Yang, Mater. Res. Bull. 47, 2264–2269 (2012)

X.H. Bu, Y.M. Zhou, M. He, Z.J. Chen, T. Zhang, Appl. Surf. Sci. 288, 444–451 (2014)

L. Yuan, X. Weng, W. Du, J. Xie, L.J. Deng, J. Alloy. Compd. 583, 492–497 (2014)

C. Hu, G. Xu, X. Shen, J. Alloy. Compd. 486, 371–375 (2009)

J. Chen, X.G. Huang, P.D. Han, L.X. Wang, Q.T. Zhang, J. Inorg. Mater. 25, 1298–1302 (2010)

X. Yan, G. Xu, J. Alloy. Compd. 491, 649–653 (2010)

C. Hu, G.Y. Xu, X.M. Shen, C.M. Shao, X.X. Yan, Appl. Surf. Sci. 256, 3459–3463 (2010)

C.D. Wen, I. Mudawar, Int. J. Heat. Mass. Transfer 49, 4279–4289 (2006)

Acknowledgments

This work was supported by the Project Funded by the National Natural Science Foundation of China (51402154), Natural Science Foundation of Jiangsu Province (BK20141000), and Natural Science Foundation of Jiangsu Provincial Universities (14KJB430019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, X., Rao, W., Chen, Y. et al. Infrared emitting properties and environmental stability performance of aluminum/polymer composite coating. J Mater Sci: Mater Electron 27, 5543–5548 (2016). https://doi.org/10.1007/s10854-016-4458-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4458-9