Abstract

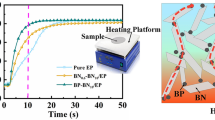

Epoxy as a type of matrix material has been extensively applied for printed circuit boards (PCBs) and electronic packaging industry. In this work, polymer matrix composites, based on epoxy modified by organosilicon resin and filled with boron nitride nanotube (BNNT) were successfully prepared. Effects of the content of BNNT and organosilicon resin respectively on the thermal conductivity (TC) of the composites were investigated. The structure of the composites was analyzed by DSC, SEM and Raman. With the increase of the BNNT content, the TC of the composites enhanced. When the BNNT content rose to 5.0 wt%, the TC value of the composite was 0.45 W/m K, about three times higher than that of neat epoxy (0.1 W/m K). Also, the addition of organosilicon resin to the former epoxy filled with BNNT (5.0 wt% filling content) benefited the improvement of the TC value of the composites, which soared to 0.79 W/m K, almost seven times greater than that of the original epoxy. The TC value of composite was 0.21 W/m K whilst the filing content of AlN reached 10 wt%. The experimental result indicated that the Tg of the composites increases, and their damping decreased. It owed to the forceful interaction between the BNNT and epoxy matrix, restraining the mobility of the epoxy chain characterized by Raman. Raman analysis showed red-shifting in the epoxy/organosilicon/BNNT composite, which evidenced good wetting around the BNNT surface by the polymer due to the effect that the organosilicon resin improved the interface interaction between the BNNT powder and the epoxy resin matrix. This resulted in an increase of the crosslinking density with the filling of BNNT powder, so heat flow network of composite system would be more easily formed. Accomplished the above great improvement, the composites are promising for use as PCB substrates.

Similar content being viewed by others

References

A. Balandin, K.L. Wang, Significant decrease of the lattice thermal conductivity due to phonon confinement in a free-standing semiconductor quantum well. Phys. Rev. B 58, 1544 (1998)

C.K. Leong, D.D.L. Chung, Carbon black dispersions as thermal pastes that surpass solder in providing high thermal contact conductance. Carbon 41, 2459 (2003)

W. Zhou, S. Qi, Q. An, H. Zhao, N. Liu, Thermal conductivity of boron nitride reinforced polyethylene composites. MRS Bull. 42, 1863 (2007)

R. Andrews, M.C. Weisenberger, Carbon nanotube polymer composite. Curr. Opin. Solid State Mater. Sci. 8, 31 (2004)

K.C. Yung, B.L. Zhu, J. Wu, T.M. Yue, C.S. Xie, Effect of AlN content on the performance of brominated epoxy resin for printed circuit board substrate. J. Polym. Sci. Part B 45, 1662 (2007)

A. Rubio, J.L. Corkill, M.L. Cohen, Theory of graphitic boron nitride nanotube. Phys. Rev. B 49, 5081 (1994)

N.G. Chopra, R.J. Luyken, K. Cherrey, V.H. Crespi, M.L. Cohen, S.G. Louie, A. Zettl, Boron nitride nanotubes. Science 269, 966 (1995)

G.X. Chen, Y.J. Li, H. Shimizu, Ultrahigh-shear processing for the preparation of polymer/carbon nanotube composites. Carbon 45, 2334 (2007)

D. Golberg, Y. Bando, C.C. Tang, C.Y. Zhi, Boron nitride nanotubes. Adv. Mater. 19, 2413 (2007)

Y. Chen, J. Zou, S.J. Campbell, G. Le Caer, Nano Au-decorated boron nitride nanotubes: conductance modification and field-emission enhancement. Appl. Phys. Lett. 84, 2430 (2004)

C.W. Chang, A.M. Fennimore, A. Afanasiev, D. Okawa, T. Ikuno, H. Garcia, D.Y. Li, A. Majumdar, A. Zettl, Isotope effect on the thermal conductivity of individual boron nitride nanotube. Phys. Rev. Lett. 97, 085901 (2006)

D.A. Stewart, I. Savic, N. Mingo, First-principles calculation of the isotope effect on boron nitride nanotube thermal conductivity. Nano Lett. 9, 81 (2009)

I. Savic, D.A. Stewart, N. Mingo, Phonon transport in isotope-disordered carbon and boron-nitride nanotubes: is localization observable? Phys. Rev. B 78, 235434 (2008)

C.W. Chang, W.Q. Han, A. Zettl, Thermal conductivity of B–C–N and BN nanotubes. J. Vac. Sci. Technol., B 23, 1883 (2005)

N.G. Chopra, A. Zettl, Measurement of the elastic modulus of a multi-wall boron nitride nanotube. Solid State Commun. 105, 297 (1998)

A.P. Suryavanshi, M.F. Yu, J.G. Wen, C.C. Tang, Y. Bando, Elastic modulus and resonance behavior of boron nitride nanotubes. Appl. Phys. Lett. 84, 2527 (2004)

D. Golberg, P.M.F.J. Costa, O. Lourie, M. Mitome, X.D. Bai, K. Kurashima, C.Y. Zhi, C.C. Tang, Y. Bando, Deformation-driven electrical transport of individual boron nitride. Nano Lett. 7, 2146 (2007)

C.Y. Zhi, Y. Bando, T. Terao, C.C. Tang, H. Kuwahara, D. Golberg, Towards thermoconductive, electrically insulating polymeric composites with boron nitride nanotubes as fillers. Adv. Fund. Mater. 19, 1857 (2009)

J. Cumings, W. Mickelson, A. Zettl, Simplified synthesis of double-wall carbon nanotubes. Solid State Commun. 126, 359 (2003)

T. Yamamoto, S. Watanabe, K. Watanabe, Universal features of quantized thermal conductance of carbon nanotubes. Phys. Rev. Lett. 92, 075502 (2004)

Y. Xiao, X.H. Yan, J.X. Cao, J.W. Ding, Y.L. Mao, J. Xiang, Specific heat and quantized thermal conductance of single-walled boron nitride nanotubes. Phys. Rev. B 69, 205415 (2004)

C. Tang, Y. Bando, T. Sato, K. Kurashima, A novel precursor for synthesis of pure boron nitride nanotubes. Chem. Commun. 12, 1290–1291 (2002)

M. Ishigami, S. Aloni, A. Zettl, Properties of boron bitride nanotubes, in Scanning Tunneling Microscopy/Spectroscopy and Related Techniques: 12th International Conference, 2004

C. Zhi, Y. Bando, T. Terao, C. Tang, D. Golberg, Dielectric and thermal properties of epozy/boron nitride nanotube composites. Pure Appl. Chem. 82, 2175 (2010)

F. Deng, Q.S. Zheng, L.F. Wang, C.W. Nan, Effects of anisotropy, aspect ratio, and nonstraightness of carbon nanotubes on thermal conductivity of carbon nanotube composites. Appl. Phys. Lett. 90, 021914 (2007)

C.W. Nan, G. Liu, Y.H. Lin, M. Li, Interface effect on thermal conductivity of carbon nanotube composites. Appl. Phys. Lett. 85, 3549 (2004)

C.W. Nan, Z. Shi, Y. Lin, A simple model for thermal conductivity of carbon nanotube-based composites. Chem. Phys. Lett. 375, 666 (2003)

Q.S. Zheng, D.X. Du, An explicit and universally applicable estimate for the effective properties of multiphase composites which accounts for inclusion distribution. J. Mech. Phys. Solids 49, 2765 (2001)

T. Xu, C.S. Xie, Tetrapod-like nano-particle ZnO/acrylic resin composite and its multi-function property. Prog. Org. Coat. 46, 297–301 (2003)

C. Zhi, Y. Bando, C. Tang, S. Honda, K. Sato, H. Kuwahara et al., Purification of boron nitride nanotubes through polymer wrapping. J Phys Chem B 110, 1525–1528 (2006)

S.K. Singhal, A.K. Srivastava, R.P. Pant, S.K. Halder, B.P. Singh, A.K. Gupta, Synthesis of boron nitride nanotubes employing mechanothermal process and its characterization. J. Mater. Sci. 43, 5243–5250 (2008)

Acknowledgments

This work was funded by the Hong Kong Innovation Technology Fund (ITF) under Project No. GHP/061/11SZ.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yung, K.C., Xu, T. & Choy, H.S. Development of high thermal conductivity via BNNTs/epoxy/organic-Si hybrid composite systems. J Mater Sci: Mater Electron 27, 5217–5224 (2016). https://doi.org/10.1007/s10854-016-4416-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4416-6