Abstract

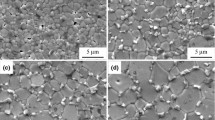

The effect of Dy2O3 doping on the microstructure, electrical and dielectric properties of ZnO–V2O5-based varistor ceramics was systematically investigated. The average grain size decreased from 5.5 to 5.2 μm to a small extent until the amount of the doped Dy2O3 reaches 0.1 mol%. The sintered densities of the doped samples also increased from 5.51 to 5.58 g/cm3 to a small extent with increasing Dy2O3 amount. The breakdown field increased from 4552 to 5117 V/cm until the amount of the doped Dy2O3 reaches 0.1 mol%. The sample doped with 0.1 mol% Dy2O3 exhibited good non-ohmic properties: 53.3 in the non-ohmic coefficient, and 0.21 mA/cm2 in the leakage current density. In addition, the dielectric constant and dissipation factor exhibited a minimum value, 713.1 and 0.205 at 0.1 mol%, respectively.

Similar content being viewed by others

References

L.M. Levinson, H.R. Pilipp, Am. Ceram. Soc. Bull. 65, 639 (1986)

T.K. Gupta, J. Am. Ceram. Soc. 73, 1817 (1990)

D.R. Clarke, J. Am. Ceram. Soc. 82, 485 (1999)

M. Matsuoka, Jpn. J. Appl. Phys. 10, 736 (1971)

K. Mukae, K. Tsuda, S. Shiga, IEEE Trans. Power Deliv. 3, 591 (1988)

C.-W. Nahm, Mater. Lett. 47, 182 (2001)

J.K. Tsai, T.B. Wu, J. Appl. Phys. 76, 4817 (1994)

J.K. Tsai, T.B. Wu, Mater. Lett. 26, 199 (1996)

C.T. Kuo, C.S. Chen, I.N. Lin, J. Am. Ceram. Soc. 81, 2942 (1998)

C.T. Kuo, C.S. Chen, I.N. Lin, J. Am. Ceram. Soc. 81, 2949 (1998)

H.H. Hng, P.L. Chan, Ceram. Int. 30, 1647 (2004)

C.-W. Nahm, Solid State Commun. 143, 4536 (2007)

H.H. Hng, K.Y. Tse, Ceram. Int. 34, 1153 (2008)

H.H. Hng, P.L. Chan, Ceram. Int. 35, 409 (2009)

C.-W. Nahm, J. Mater. Sci. Mater. Electron. 24, 27 (2013)

C.-W. Nahm, J. Mater. Sci. Mater. Electron. 24, 4839 (2013)

C.-W. Nahm, J. Mater. Sci. Mater. Electron. 26, 168 (2015)

C.-W. Nahm, J. Mater. Sci. Mater. Electron. 26, 4144 (2015)

J.C. Wurst, J.A. Nelson, J. Am. Ceram. Soc. 55, 109 (1972)

M. Mukae, K. Tsuda, I. Nagasawa, Jpn. J. Appl. Phys. 16, 1361 (1977)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nahm, CW. Effect of Dy2O3 doping on microstructure, electrical and dielectric properties of ZnO–V2O5-based varistor ceramics. J Mater Sci: Mater Electron 26, 10217–10224 (2015). https://doi.org/10.1007/s10854-015-3874-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3874-6