Abstract

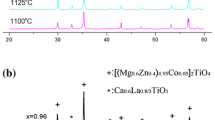

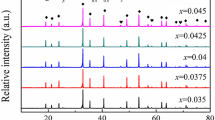

Ca0.66La0.387Ti0.88O3 microwave dielectric ceramics were prepared via a mixed oxide solid state sintering route and characterized. X-ray diffraction revealed the formation of single phase Ca0.66La0.387Ti0.88O3 ceramics with orthorhombic (Pbnm) symmetry within the detection limit of the in-house XRD facility. Raman spectroscopy revealed the presence of seven Raman active bands evident of orthorhombic symmetry, in agreement with the present X-ray diffraction results. The microstructure of sintered samples appeared almost dense with some occasional pores. Ca0.66La0.387Ti0.88O3 exhibited reasonable relative permittivity (~71.5) and quality factor (~13,407 GHz); however, its temperature coefficient of resonance frequency was high (~136.4 × 10−6/°C) for commercial applications and requires further optimization.

Similar content being viewed by others

References

R. Muhammad, Y. Iqbal, C. Rambo, H. Khan, Int. J. Mater. Res. 105, 431 (2014)

P.L. Wise, I.M. Reaney, W.E. Lee, T.J. Price, D.M. Iddles, D.S. Cannell, J. Eur. Ceram. Soc. 21, 1723 (2001)

R. Muhammad, Y. Iqbal, J. Mater. Sci. Mater. Electron. 24, 2322 (2013)

Y. Iqbal, A. Manan, I. Reaney, Mater. Res. Bull. 46, 1092 (2011)

I.N. Jawahar, N.I. Santha, M.T. Sebastian, P. Mohanan, J. Mater. Res. 17, 3084 (2002)

Y. Tohdo, K. Kakimoto, H. Ohsato, H. Yamada, T. Okawa, J. Eur. Ceram. Soc. 26, 2039 (2006)

N. Kisel, T. Limar, L. Mudrolyubova, I. Cherednichenko, Inorg. Mater. 10, 399 (1974)

A. Larson, R. Von Dreele, General Structure Analysis System (GSAS), Los Alamos National Laboratory Report LAUR 86-748 (1994)

B.H. Toby, J. Appl. Crystallogr. 34, 210 (2001)

R. Muhammad, Y. Iqbal, C. Rambo, J. Mater. Sci. Mater. Electron. (2015). doi:10.1007/s10854-014-2662-z

R. Muhammad, Y. Iqbal, C. Rambo, J. Mater. Sci. Mater. Electron. 26, 1918 (2015)

R.D. Shannon, Acta Crystallogr. Sect. A 32, 751 (1976)

M. Saleem, Y. Iqbal, S. Qin, X. Wu, R. Muhammad, F. Zhu, J. Mater. Sci. Mater. Electron. 26, 1507 (2015)

I. Levin, J. Chan, J. Maslar, T. Vanderah, S. Bell, J. Appl. Phys. 90, 904 (2001)

H. Zheng, I. Reaney, G. Gyorgyfalva, R. Ubic, J. Yarwood, M. Seabra, V. Ferreira, J. Mater. Res. 19, 488 (2004)

H. Zheng, G. Gyorgyfalva, R. Quimby, H. Bagshaw, R. Ubic, I. Reaney, J. Yarwood, J. Eur. Ceram. Soc. 23, 2653 (2003)

Acknowledgments

The laboratory support extended by Prof. I.M. Reaney and his group, Electro-ceramics Laboratory, Department of Material Science and Engineering, University of Sheffield (UK) for microwave properties measurements, is highly acknowledged. The authors acknowledge the financial support (ADP# 130314) of the Khyber Pakhtunkhwa Government through the Directorate of Science and Technology, KP for the up-gradation of Materials Research Laboratory, University of Peshawar.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We have no potential conflict of interest.

Rights and permissions

About this article

Cite this article

Muhammad, R., Iqbal, Y. Structure and microwave dielectric properties of Ca0.66La0.387Ti0.88O3 ceramics. J Mater Sci: Mater Electron 26, 9092–9096 (2015). https://doi.org/10.1007/s10854-015-3596-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3596-9