Abstract

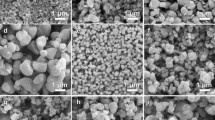

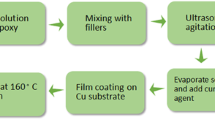

In this study, calcium copper titanate, CaCu3Ti4O12 (CCTO) was used as filler in epoxy composite using different mixing and fabrication methods to investigate their suitability as dielectric materials for embedded capacitor. Results show that 20 vol% CCTO/epoxy composite produced using ultrasonic mixing method yield slightly higher dielectric constant, T 5% and T onset as compared to 20 vol% CCTO/epoxy composite produced using agate mortar method. Meanwhile, sample with 20 vol% CCTO/epoxy composite fabricated using spin coating method shows slightly higher dielectric constant, T 5%, T onset and E′, and lower CTE value compared to 20 vol% CCTO/epoxy composite fabricated using hot press method. Nevertheless, 40 vol% CCTO/epoxy composite fabricated using hot press method shows the highest dielectric constant, T 5%, T onset and E′, and lowest CTE value compared to all composites. In short, composite produced using ultrasonic as mixing method and spin coating as fabrication method are suitable to be utilized to produce epoxy composite as dielectric materials for embedded capacitor applications.

Similar content being viewed by others

References

S.M. Wu, E. Jahja, W.K. Yen, J.W. Wang, in Proceedings of the Electronic Packaging Technology Conference, pp. 125–129 (2007)

Y. Rao, S. Ogitani, P. Kohl, C.P. Wong, J. Appl. Polym. Sci. 83, 1084–1090 (2002)

J.R. Yoon, J.W. Han, K.M. Lee, Trans. Electr. Electron. Mater. 10, 116–120 (2009)

M.A. Alam, M.H. Azarian, M. Osterman, M. Pecht, Microelectron. Reliabil. 51, 946–952 (2011)

M.A. Subramanian, D. Li, N. Duan, B.A. Reisner, A.W. Sleight, J. Solid State Chem. 151, 323–325 (2000)

C.C. Homes, T. Vogt, S.M. Shapiro, S. Wakimoto, A.P. Ramirez, Science 293, 673–676 (2001)

R. Voo, M. Mariatti, L.C. Sim, Polym. Adv. Technol. 23, 1620–1627 (2012)

A. Seema, K.R. Dayas, J.M. Varghese, J. Appl. Polym. Sci. 106, 146–151 (2007)

J.C. Li, D.C. Ba, Y.L. Song, in Organic Nanostructured Thin Film Devices and Coatings for Clean Energy, ed. by S. Zhang (CRC Press, NY, 2010), pp. 189–201

G. Nan, Buletinul Universiti Petrol. 8(2), 99–102 (2006)

X. He, in Methodological Advances in the Culture, Manipulation and Utilization of Embryonic Stem Cells for Basic and Practical Applications, ed. by C. Atwood (InTech, 2011), pp. 113–138

J.M. Julie, D.H. Sabar, A. Fadzil, D. Karim, A.A. Zainal, Mater. Lett. 61, 1835–1838 (2007)

A.R. Fariz, D.H. Sabar, A.A. Zainal, A. Fadzil, J.M. Julie, J. Mater. Sci.: Mater. Electron. 26, 3947–3956 (2015)

L. Zheng, D. Zheng, H. Xin, W. Li, M. Zhu, H. Feng, W. Sun, IEEE Trans. Mag. 50, 1–4 (2014)

N.G. Devaraju, E.S. Kim, B.I. Lee, Microelectron. Eng. 82(1), 71 (2005)

L.A. Ramajo, M.A. Ramírez, P.R. Bueno, Mater. Res. 11(1), 85–88 (2008)

S.H. Xie, B.K. Zhu, J.B. Li, X.Z. Wei, Z.K. Xu, Polym. Test. 23, 797–801 (2004)

A. Leszczynska, J. Njuguna, K. Pielichowski, J.R. Banerjee, Thermochim. Acta 454, 75–96 (2007)

P. Thomas, R.S.E. Ravindran, K.B.R. Varma, J. Therm. Anal. Calorim. 115, 1311–1319 (2013)

B. Shriprakash, K.B.R. Varma, Compos. Sci. Technol. 67, 2363–2368 (2007)

E. Tuncer, I. Sauers, D.R. James, R. Alvin, M. Ellis, P. Paranthaman, A.T. Tolga, S. Sathyamurthy, L.M. Karren, J. Li, A. Goyal, Nanotechnology 18, 25703–25706 (2007)

F. Amaral, C.P.L. Rubinger, F. Henry, L.C. Costa, M.A. Valente, A.B. Timmons, J. Non-Cryst. Solids 354, 5321–5322 (2008)

L.Q. Ibrhium, M.M. Ismail, B.M. Aldabbagh, J. Appl. Phys. 5, 49–54 (2013)

J.M. Park, D.S. Kim, J.R. Lee, T.W. Kim, J. Mater. Sci. Eng.: C 23, 971–975 (2003)

N. Chisholm, H. Mahfuz, V.K. Rangari, A. Ashfaq, S. Jeelani, Compos. Struct. 67, 115–124 (2004)

G. Suriati, M. Mariatti, A. Azizan, Mold. J. Phys. Sci. 11, 94–105 (2012)

Acknowledgments

The authors gratefully acknowledge the support of the Universiti Sains Malaysia and the Ministry of Education, and Explorating Research Grant Scheme (ERGS) for granting the research fund used for this project (Project No. 6730109).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saidina, D.S., Norshamira, A. & Mariatti, M. Dielectric and thermal properties of CCTO/epoxy composites for embedded capacitor applications: mixing and fabrication methods. J Mater Sci: Mater Electron 26, 8118–8129 (2015). https://doi.org/10.1007/s10854-015-3471-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3471-8