Abstract

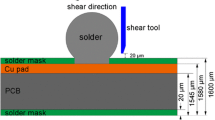

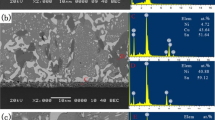

This research was intended to establish a scientific relationship between the changes of the weight percent of CNTs in the solder blocks and the changes of mechanical properties of the doped solder joints. The impact of reflow soldering induced dopant redistribution has been detailedly discussed. It was proved to be a principle reason that led to the changes of the weight percent of CNTs in the doped solder joints, and finally influenced the mechanical properties. The drag force caused by the outward flow of the solder flux and the buoyancy force caused by the density gap were the main inducing factors for the redistribution. By experimental methods, CNTs doped Sn58Bi solder pastes with the doping amount of 0.025, 0.05, 0.100, 0.150 and 0.200 wt% were studied to analyze this phenomenon. Our findings showed that with doping amount of 0.100 wt%, the doped solder block seemed saturated. After doping more CNTs, the final weight percent of CNTs was hardly increased. Also, the excess CNTs preferred to aggregate at the near surface region of the solder block, making the surface became darker and coarser. To analyze the real conditions, CNTs doped Sn58Bi solder joints with different original doping amount were studied to detect the changes of mechanical properties. According to the results, the highest shear stress was found to be 77.3 MPa with the doping amount of 0.050 wt%. After the doping amount overpassed 0.100 wt%, the shear stress decreased sharply. Also, via morphology observation, the doped CNTs were found aggregated at the interface of the solder joints seriously with the doping amount of 0.200 wt%.

Similar content being viewed by others

References

A.A. El-Daly, A.E. Hammad, Mater. Des. 40, 292 (2012)

A.E. Hammad, A.M. El-Taher, J. Electron. Mater. 43(11), 4146 (2014)

S.K. Lina, T.L. Nguyena, S.C. Wua, Y.H. Wanga, J. Alloys Compd. 586, 319 (2014)

Y. Tang, G.Y. Li, D.Q. Chen, Y.C. Pan, J. Mat. Sci Mater. Electron. 25(2), 981 (2014)

A.A. El-Daly, G.S. Al-Ganainy, A. Fawzy, M.J. Younis, Mater. Des. 55, 837 (2014)

L.C. Tsao, R.W. Wu, T.-H. Cheng, K.-H. Fan, R.S. Chen, Mater. Des. 50, 774 (2013)

L. Shen, Z.Y. Tan, Z. Chen, Mater. Sci. Eng. A 561, 232 (2013)

L. Yang, C. Du, J. Dai, N. Zhang, Y. Jing, J. Mat. Sci Mater. Electron. 24(11), 4180 (2013)

S. Xu, Y.C. Chan, K. Zhang, K.C. Yung, J. Alloys Compd. 595, 92 (2014)

X. Hu, Y.C. Chan, K. Zhang, K.C. Yung, J. Alloys Compd. 582, 162 (2013)

S.L. Soo, Instrumentation for fluid particle flow (Noyes publications, Park Ridge, 1999), pp. 375–377

H.Y. Sun, Q.Q. Li, Y.C. Chan, J. Mat. Sci Mater. Electron. 25(10), 4380 (2014)

R. Peter King, Introduction to practical fluid flow (Elsevier Science, Burlington, 2002), pp. 55–66

K. Nogi, M. Hosokawa, M. Naito, T. Yokoyama, Nanoparticle technology handbook, 2nd edn. (Elsevier, Amsterdam, 2012), pp. 119–121

Acknowledgments

The authors would like to acknowledge the financial support provided by the National Natural Science Foundation of China/Research Grants Council of Hong Kong (NSFC/RGC), Ref. No. 9054008/N_CityU101/12.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, H., Chan, Y.C. & Wu, F. The impact of reflow soldering induced dopant redistribution on the mechanical properties of CNTs doped Sn58Bi solder joints. J Mater Sci: Mater Electron 26, 5318–5325 (2015). https://doi.org/10.1007/s10854-015-3071-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3071-7