Abstract

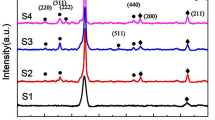

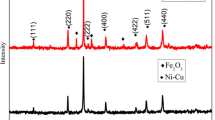

BaZn1.2Co0.8Fe16O27 ferrites were synthesized by a combined citrate–EDTA complexing method, and then the ferrites were mixed with multi-walled carbon nanotubes (MWCNTs) to prepare microwave absorbing composites. The morphology of ferrites and MWCNTs were observed using SEM. The microwave electromagnetic properties of ferrite–MWCNTs composites have been measured by a network analyzer (Agilent 8722ET) in the frequency range of 2–18 GHz. The theoretical reflection loss (RL) values of the composites were obtained according to the transmission line theory. In this work, the ferrite–5 wt% MWCNTs composite obtained a thinner matching thickness of 0.8 mm, with a RL maximum of −10 dB and absorption band (less than −5 dB) from 7 to 15 GHz, being promising microwave absorbing material.

Similar content being viewed by others

References

S.R. Jigajeni, M.M. Sutar, S.M. Salunkhe, P.B. Joshi, J. Mater. Sci. Mater. Electron. 23, 1678 (2012). doi:10.1007/s10854-012-0646-4

G.R. Gordani, A. Ghasemi, A. Saidi, J. Magn. Magn. Mater. 363, 49–54 (2014). doi:10.1016/j.jmmm.2014.03.068

X.G. Huang, J. Zhang, S.R. Xiao, G.S. Chen, J. Am. Ceram. Soc. 97(5), 1363–1366 (2014). doi:10.1111/jace.12909

S. Sharma, V. Singh, R.K. Kotnala, R.K. Dwivedi, J. Mater. Sci. Mater. Electron. 25, 1915 (2014). doi:10.1007/s10854-014-1820-7

A.L. Xia, S.K. Liu, C.G. Jin, S.B. Su, J. Mater. Sci. Mater. Electron. 23, 4166 (2013). doi:10.1007/s10854-013-1377-x

X.G. Huang, J. Zhang, S.R. Xiao, T.Y. Sang, G.S. Chen, Mater. Lett. 124, 126–128 (2014). doi:10.1016/j.matlet.2014.03.049

D. Micheli, A. Vricella, R. Pastore, M. Marchetti, Carbon 77, 756–774 (2014). doi:10.1016/j.carbon.2014.05.080

J. Zhang, L.X. Wang, M.P. Liang, Q.T. Zhang, T. Nonferr. Metal. Soc. 24(1), 131–135 (2014). doi:10.1016/S1003-6326(14)63038-7

Q.C. Ling, J.Z. Sun, Q. Zhao, Q.Y. Zhou, Mater. Sci. Eng. B 162(3), 162–166 (2009). doi:10.1016/j.mseb.2009.03.023

D.A. Makeiff, T. Huber, Synth. Met. 156, 497–505 (2006). doi:10.1016/j.synthmet.2005.05.019

E.J. Vanzura, J.R. Baker-jarvis, J.H. Grosvenor, IEEE Trans. Microw. Theory Tech. 42(11), 2063–2069 (1994). doi:10.1109/22.330120

A. Paul, S. Thomas, J. Appl. Polym. Sci. 63, 247–266 (1997). doi:10.1002/(SICI)1097-4628(19970110

K.S. Moon, H.D. Cho, A.K. Lee, K.Y. Cho, H.G. Yoon, K.S. Suh, J. Appl. Polym. Sci. 77, 1294–1302 (2000). doi:10.1002/1097-4628(20000808)77:6<1294:AID-APP14>3.0.CO;2-E

S. Sugimoto, S. Kondo, K. Okayama, H. Nakamura, IEEE Trans. Magn. 35(5), 3154–3160 (1999). doi:10.1109/20.801112

T. Maeda, S. Sugimoto, T. Kagotani, N. Tezuka, K. Inomata, J. Magn. Magn. Mater. 281, 195–205 (2004). doi:10.1016/j.jmmm.2004.04.105

Acknowledgments

This work was financially supported by the National Natural Science Foundation (51202111), and Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Zhang, J. & Zhang, Q. The effect of MWCNTs on the microwave electromagnetic properties of ferrite–MWCNTs composites. J Mater Sci: Mater Electron 26, 1895–1899 (2015). https://doi.org/10.1007/s10854-014-2626-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2626-3