Abstract

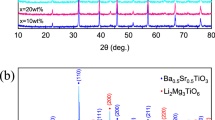

(1−x) Ba0.5Sr0.5TiO3–xMgMoO4 (x = 0, 5, 10, 20 and 30 wt%) composite ceramics were prepared via solid state reaction processing. Their structure and dielectric properties were systematically characterized. The introduction of MgMoO4 resulted in a change in lattice constant of the perovskite phase and partial reaction between MgMoO4 and Ba0.5Sr0.5TiO3 occurred in the sintering process. Both X-Ray Diffraction (XRD) and Back-scattered Electron Images (BEI) analysis show the co-existence of three phase structures of BST, MgMoO4 and BaMoO4. With increasing of MgMoO4 content, the tunability of the composite ceramics was decreased due to the increase of the amount of non-ferroelectric phases. The Curie temperature Tc of the samples gradually shifted to low temperatures with increasing of MgMoO4 content. Dielectric constant can be adjusted in the range from 2035 to 150, meanwhile maintain a relatively high tunability and Q values. The sample with 20 wt% MgMoO4 possesses a tunability of 10 %, a low dielectric constant of 111 and an appropriate Q value of 183 (2.240 GHz), which meet the requirements of high power and impedance matching, thus making it a promising candidate for applications as electrically tunable microwave devices.

Similar content being viewed by others

References

A.K. Tagantsev, V.O. Sherman, K.F. Astafiev, J. Venkatesh, N. Setter, J. Electroceram. 11, 5 (2003)

E.A. Nenasheva, A.D. Kanareykin, N.F. Kartenko, A.I. Dedyk, S.F. Karmanenko, J. Electroceram. 13, 235 (2004)

L.C. Sengupta, S. Sengupta, Mater. Res. Innov. 2, 278 (1999)

E.A. Nenasheva, A.D. Kanareĭkin, A.I. Dedyk, Y.V. Pavlova, Phys. Solid State 51, 1557 (2009)

S. Wu, S. Wang, L. Chen, X. Wang, J. Mater. Sci. sMater. Electron. 19, 505 (2008)

U.C. Chung, C. Elissalde, M. Maglione, C. Estournes, M. Pate, J.P. Ganne, Appl. Phys. Lett. 92, 042902 (2008)

Y. Chen, X.-L. Dong, R.-H. Liang, J.-T. Li, Y.-L. Wang, J. Appl. Phys. 98, 064107 (2005)

X. Chou, J. Zhai, X. Yao, Appl. Phys. Lett. 91, 122908 (2007)

G. Hu, F. Gao, L. Liu, X. Cao, Z. Liu, Ceram. Int. 37, 1321 (2011)

G.-K. Choi, J.-R. Kim, S.H. Yoon, K.S. Hong, J. Eur. Ceram. Soc. 27, 3063 (2007)

J. Zhang, J. Zhai, X. Chou, X. Yao, J. Am. Ceram. Soc. 91, 3258 (2008)

G. Burns, F.H. Dacol, Phys. Rev. B. 28, 2527 (1983)

D. Viehland, S.J. Jang, L.E. Cross, M. Wuttig, Phys. Rev. B 46, 8003 (1992)

H. Yu, Z.-G. Ye, J. Appl. Phys. 103, 034114 (2008)

T. Teranishi, T. Hoshina, H. Takeda, T. Tsurumi, J. Appl. Phys. 105, 054111 (2009)

J. Zhang, J. Zhai, X. Chou, X. Yao, Solid State Commun. 147, 392 (2008)

Acknowledgments

This research was supported by the Ministry of Sciences and Technology of China through 973-project under Grant 2009CB623302, the Cultivation Fund of the Key Scientific and Technical Innovation Project, Ministry of Education of China (No.707024).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, L., Wang, J., Zhai, J. et al. Dielectric tunable properties of Ba0.5Sr0.5TiO3–MgMoO4 composite ceramics for microwave applications. J Mater Sci: Mater Electron 24, 2576–2580 (2013). https://doi.org/10.1007/s10854-013-1136-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1136-z