Abstract

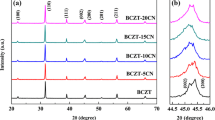

Lead-free (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3-xwt.%Y2O3 (BCZT-xY) piezoelectric ceramics have been synthesized using solid-state reaction technique and the effects of Y2O3 addition on the phase structure and piezoelectric properties of the ceramics have been studied. The results reveal that the addition of Y2O3 significantly improves the sinterability of BCZT ceramics, resulting in a reduction of sintering temperature from 1,540 to 1,350 °C, and an increase of the Curie temperature T C from 85 to 95 °C. X-ray diffraction data shows that Y2O3 diffuses into the lattice of BCZT-xY ceramics and a pure perovskite phase forms in the ceramics. Scanning electron microscopy images indicate that a small amount of Y2O3 addition affects the microstructure, obviously. Main piezoelectric parameters of these ceramics are optimized around x = 0.06 wt % with a large piezoelectric coefficient (d 33 = 560 pC/N), a high planar electromechanical coefficient (k p = 53 %) and a low dissipation factor (tan δ = 0.9 %) at 1 kHz. The results indicate that the BCZT-xY ceramics are promising lead-free materials for practical applications.

Similar content being viewed by others

References

B. Noheda, D.E. Cox, G. Shirane, R. Guo, B. Jones, L.E. Cross, Phys. Rev. B 63, 14103 (2000)

C. Eric, Nature 432, 24 (2004)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Nature 432, 84 (2004)

M. Jiang, Y. Liu, G. Chen, J. Chen, J. Mater. Sci.: Mater. Electron. 22, 876 (2011)

C. Zhou, Y. Liu, W. Li, C. Yuan, J. Mater. Sci.: Mater. Electron. 21, 364 (2010)

K. Ramam, M. Lopez, Mater. Sci. Eng. B 145, 41 (2007)

W.F. Liu, X.B. Ren, Phys. Rev. Let. 103, 257602 (2009)

P. Wang, Y.X. Li, Y.Q. Lu, J. Eur. Ceram. Soc. 31, 2005 (2011)

S.W. Zhang, H.L. Zhang, B.P. Zhang, S. Yang, J. Alloys. Comp. 506, 131 (2010)

W. Li, Z.J. Xu, R.Q. Chu, P. Fu, G.Z. Zang, J. Am. Ceram. Soc. 94, 3181 (2011)

S.W. Zhang, H.L. Zhang, B.P. Zhang, G.L. Zhao, J. Eur. Ceram. Soc. 29, 3235 (2009)

W. Li, Z.J. Xu, R.Q. Chu, P. Fu, G.Z. Zang, J. Am. Ceram. Soc. 93, 2942 (2010)

C. Zhou, X. Liu, W. Li, C. Yuan, Mater. Res. Bull. 44, 724 (2009)

Acknowledgments

The authors wish to acknowledge the financial support of the National Nature Science Foundations, grant No. 51102055, and Guangxi Nature Science Foundations, grant No.2010GXNSFD013007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, Y., Yuan, C., Liu, X. et al. Lead-free (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3-Y2O3 ceramics with large piezoelectric coefficient obtained by low-temperature sintering. J Mater Sci: Mater Electron 24, 654–657 (2013). https://doi.org/10.1007/s10854-012-0785-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0785-7