Abstract

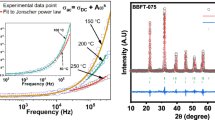

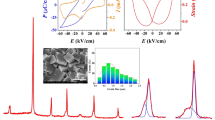

Nb5+ doped 0.63Bi(Mg1/2Ti1/2)O3–0.37PbTiO3 (0.63BMT–0.37PT + xNb5+) ceramics have been fabricated by means of citrate sol–gel method and ordinary sintering. Effects of Nb5+ doping on the densification and various electrical properties were studied. The results indicated that the addition of a small amount of Nb5+ gradually changes the crystal structure from a typical rhombohedral-tetragonal coexisted structure to a nearly pure rhombohedral structure. A slight amount of secondary phases start to appear as the doping content of Nb5+ is more than 1.5 mol%, indicating that the solubility limit of Nb5+ in the matrix composition is reached. Moreover, electrical properties of the sintered ceramics were obviously changed based on the effect of densification and ionic substitution. 0.63BMT–0.37PT + 0.005Nb5+ ceramics sintered at 1,020 °C exhibit optimum properties of piezoelectric constant d33 ~ 245 pC/N, planar electromechanical coupling factor kp ~ 30 %, \( \varepsilon_{33}^{\text{T}} /\varepsilon_{\text{o}} \) ~ 1,220, and Tc ~ 460 °C.

Similar content being viewed by others

References

C.A. Randall, R. Eitel, B. Jones, T.R. Shrout, J. Appl. Phys. 95, 3633 (2004)

Q. Zhang, Z.R. Li, F. Li, Z. Xu, X. Yao, J. Am. Ceram. Soc. 93, 3330 (2010)

J. Chen, X.L. Tan, W. Jo, J. Rödel, J. Appl. Phys. 106, 034109 (2009)

M.D. Snel, W.A. Groen, G. de With, J. Eur. Ceram. Soc. 25, 3229 (2005)

S. Sharma, D.A. Hall, J. Mater. Sci.: Mater. Electron. 21, 405 (2010)

A. Moure, M. Alguer′o, L. Pardo, E. Ringgaard, A.F. Pedersen, J. Eur. Ceram. Soc. 27, 237 (2007)

S.H. Yu, Y. Ye, H.T. Huang, L.M. Zhou, Z.Q. Wang, Proc. of SPIE 6423, 64234H (2007)

S.M. Ke, H.T. Huang, S.H. Yu, L.M. Zhou, J. Appl. Phys. 107, 084112 (2010)

M. Villegas, C. Moure, J.R. Jurado, P. Durán, J. Mater. Sci. 29, 4975 (1994)

S.J. Yoon, A. Joshi, K. Uchino, J. Am. Ceram. Soc. 80, 1035 (1997)

R.B. Atkin, R.M. Fulrath, J. Am. Ceram. Soc. 54, 265 (1971)

R.B. Atkin, R.L. Holman, R.M. Fulrath, J. Am. Ceram. Soc. 54, 113 (1971)

E.S. Machlin, Trans. AIME 224, 1153 (1962)

P. Gordon, R.A. Vandermeer, Trans. AIME 224, 917 (1962)

C.A. Randall, S.A. Markgraf, A.S. Bhalla, K. Baba-Kishi, Phys. Rev. B 40, 413 (1989)

Acknowledgments

This work was financially supported by a project of Natural Science Foundation of Anhui Province (1108085J14), the National Natural Science Foundation of China (50972035), a Program for New Century Excellent Talents in University, State Education Ministry (NCET-08-0766) and 973 Program (No. 2009CB623301).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, X., Zuo, R., Zuo, W. et al. Sintering and electrical properties of Nb5+ doped 0.63Bi(Mg1/2Ti1/2)O3–0.37PbTiO3 piezoelectric ceramics. J Mater Sci: Mater Electron 23, 2162–2166 (2012). https://doi.org/10.1007/s10854-012-0733-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0733-6