Abstract

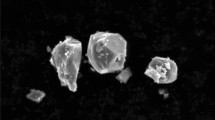

The effect of Ti on the solid state reactions between Sn and Ni has been investigated in this work. Based on the experimental results the following statements can be made: Firstly, the presence of Ti does not have measurable effects on the thickness evolution of Ni3Sn4 during solid state annealing. Secondly, the results from long term heat treatments show that there is no marked solubility of Ti to Ni3Sn4. Rather Ti reacts with Sn to form large Ti2Sn3 platelets inside the solder matrix. The Sn-rich part of the Ni–Sn–Ti phase diagram was assessed in order to rationalize the experimental results. By utilizing this information, the absence of any marked effects of Ti on the growth of Ni–Sn intermetallic compounds (IMC) was analysed. As there is no solubility of Ti to SnAg solder or to Ni–Sn IMC’s, Ti cannot change activities of components in the solder nor influence the stability of the IMC layers. Hence, these results throw significant doubts over the concept of trying to influence the Ni–Sn IMC layer thickness or quality by Ti alloying.

Similar content being viewed by others

References

Z. Huang, P. Conway, R. Thompson, Microelectron. Reliab. 47, 1997 (2007)

C. Ho, S. Yang, C.R. Kao, J. Mater. Sci.: Mater. Electron. 18, 155 (2007)

X. Zhang, Y. Zhan, Q. Guo, G. Zhang, J. Hu, J. Alloys Compd. 480(2), 382 (2009)

T. Laurila, V. Vuorinen, M. Paulasto-Kröckel, Mater. Sci. Eng. R R68, 1–38 (2010)

T. Takemoto, T. Yamamoto, J. JCBRA 40(1), 309 (2001)

K. Kim, S. Huh, K. Suganuma, Microelectr. Reliab. 43, 259 (2003)

V. Vuorinen, H.Q. Dong, T. Laurila, J. Mater. Sci. Mater. Electron. 23(16), 68 (2012)

W. Liu, P. Bachorik, N.-C. Lee, in Proceedings of the 10th Electronics Packaging Conference, (EPTC, Singapore, 2008), pp. 9–12.12

K. Santhy, K.C. Hari Kumar, Intermetallics 18, 1713–1721 (2010)

G. Ghosh, Metall. Mater. Trans. A 30A, 1481–1494 (1991)

J. Wang, C. Liu, C. Leinenbach, U.E. Klotz, P.J. Uggowitzer, CALPHAD 35, 82–94 (2011)

Y.V. Stadnyk, R.V. Skolozdra, Izvestiya Akademii Nauk SSSr, Neorganichesjie Materialy, 27, 2209–2210 (1991)

D.-Y. Jung, K. Kurosaki, C.-E. Kim, H. Muta, S. Yamanaka, J. Alloys Compd. 489, 328–331 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Laurila, T., Hongqun, D. & Vuorinen, V. Interfacial reactions between SnAg1.0Ti and Ni metallization. J Mater Sci: Mater Electron 23, 2030–2034 (2012). https://doi.org/10.1007/s10854-012-0698-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0698-5