Abstract

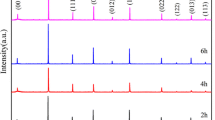

Plate-like BaBi4Ti4O15 powders were used to fabricate 0.952[Ba(Zr0.2Ti0.8)O3–(Ba0.7Ca0.3)TiO3]–0.048BaBi4Ti4O15(abbr. BZCT-BBT) ceramics by tape casting. The microstructure and dielectric relaxor behaviors of BZCT-BBT ceramics were investigated. BZCT-BBT ceramics can be sintered well at 1,100 °C and mainly consisted of tetragonal perovskite phase and BaBi4Ti4O15 (abbr. BBT) phase. The lattice constants decrease as the sintering temperature increases due to substitution of Bi3+ for the A-site atoms of the perovskite structure. There is no obvious difference between the structure in the perpendicular and parallel directions, however, an evident difference of dielectric properties in the two directions is observed. Comparing with Ba(Zr0.2Ti0.8)O3–(Ba0.7Ca0.3)TiO3(abbr. BZCT) ceramics, BZCT-BBT ceramics show obvious relaxor characteristics which are evidenced by the degree of diffuseness γ calculated using the modified Curie–Weiss law. Meanwhile, the addition of BBT decreases Tm, which results from the decrease of grain size. The reduction of εm is mainly caused by phase structure deviation from the coexisting rhombohedral and tetragonal structure to single tetragonal.

Similar content being viewed by others

References

E.M. Sabolsky, L. Maldonado, M.M. Seabaugh, S.L. Swartz, J. Electroceram. 25, 77 (2010)

L.A. Schmitt, J. Kling, M. Hinterstein, M. Hoelzel, W. Jo, H.J. Kleebe, H. Fuess, J. Mater. Sci. 46, 4368 (2011)

T. Takenaka, H. Nagata, J. Eur. Ceram. Soc. 25, 2693 (2005)

F. Gao, C.S. Zhang, X.C. Liu, L.H. Cheng, C.S. Tian, J. Eur. Ceram. Soc. 27, 3453 (2007)

S. Danwittayakul, N. Vaneesorn, S. Jinawath, A. Thanaboonsombut, Ceram. Int. 34, 765 (2008)

F. Gao, L.H. Cheng, R.Z. Hong, J.J. Liu, Y.H. Yao, C.S. Tian, J. Mater. Sci. Mater. Electron. 19, 1228 (2008)

Y.Q. Huang, Y.X. Liu, L.F. Gao, T.T. Liu, G.X. Zhang, J. Mater. Sci. Mater. Electron. 21, 1055 (2010)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Nature 432, 84 (2004)

Y.P. Guo, K. Kakimoto, H. Ohsato, Appl. Phys. Lett. 85, 4121 (2004)

D.J. Gao, K.W. Kwok, D.M. Lin, H.L.W. Chan, J. Phys. D Appl. Phys. 42, 035411 (2009)

T.A. Skidmore, T.P. Comyn, S.J. Miline, J. Am. Ceram. Soc. 93, 624 (2010)

D.M. Lin, K.W. Kwok, J. Mater. Sci. Mater. Electron. (2011). doi:10.1007/s10854-011-0425-7

B. Shao, J.H. Qiu, K.J. Zhu, X.M. Pang, Q.H. Meng, J. Mater. Sci. Mater. Electron. (2011). doi:10.1007/s10854-011-0504-9

S.W. Zhang, H.L. Zhang, B.P. Zhang, G.L. Zhao, J. Eur. Ceram. Soc. 29, 3235 (2009)

W.F. Liu, X.B. Ren, Phys. Rev. Lett. 103, 257602 (2009)

S.W. Zhang, H.L. Zhang, B.P. Zhang, S. Yang, J. Alloy. Compd. 506, 131 (2010)

P. Wang, Y.X. Li, Y.Q. Lu, J. Eur. Ceram. Soc. 31, 2005 (2011)

W. Li, Z.J. Xu, R.Q. Chu, P. Fu, G.Z. Zang, Mater. Sci. Eng., B 176, 65 (2011)

R.Z. Hong, F. Gao, J.J. Liu, Y.H. Yao, C.S. Tian, J. Mater. Sci. 43, 6126 (2008)

F. Gao, R.Z. Hong, J.J. Liu, Y.H. Yao, C.S. Tian, J. Eur. Ceram. Soc. 28, 2063 (2008)

S. Kumar, K.B.R. Varma, Curr. Appl. Phys. 11, 203 (2011)

A. Chakrabarti, J. Bera, J. Alloy. Compd. 505, 668 (2010)

F. Gao, L.H. Cheng, R.Z. Hong, J.J. Liu, Y.H. Yao, C.S. Tian, J. Mater. Sci. Mater. Electron. 19, 1228 (2008)

H. Yilmaz, G.L. Messing, S.T. Mckinstry, J. Electroceram. 11, 207 (2003)

A. Chakrabarti, J. Bera, Curr. Appl. Phys. 10, 574 (2010)

J.D. Bobić, M.M. Vijatović, S. Greičius, J. Banys, B.D. Stojanović, J. Alloy. Compd. 499, 221 (2010)

L.E. Cross, Ferroelectrics 76, 241 (1987)

V.V. Shvartsman, D.C. Lupascu, J. Am. Ceram. Soc. 95, 1 (2012)

Acknowledgments

This work was supported by Aviation Science Foundation of China (2009ZF53061), Xi’an Applied Materials Innovation Fund Application (XA-AM-200808) and Postgraduate Starting Seed Foundation of Northwestern Polytechnical University (Z2011003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, B., Gao, F., Cao, X. et al. Microstructure and dielectric relaxor behavior of Ba(Zr0.2Ti0.8)O3–(Ba0.7Ca0.3)TiO3–BaBi4Ti4O15 ceramics by tape casting. J Mater Sci: Mater Electron 23, 1809–1816 (2012). https://doi.org/10.1007/s10854-012-0667-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0667-z