Abstract

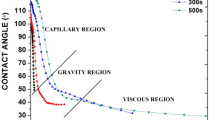

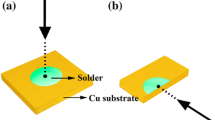

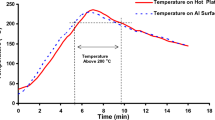

Eliminating lead in electronics is an environmental consciousness that is taken prior to manufacturing. Lead-free solder has recently been developed to advance that goal. One of the most common types of lead-free solder is Sn–Ag–Cu(SAC). Adding alloying elements can modify the properties of SAC. The present study is devoted to the research and development of SAC for microelectronic packaging applications. The effects of iron and indium addition to SAC were investigated. Four different samples were fabricated by casting: Sn–3.6Ag–0.9Cu, Sn–3.6Ag–0.9Cu–0.2Fe, Sn–3.6Ag–0.9Cu–0.6Fe, and SAC-InCe. Reliability tests were done on Cu and Ni–P substrate. The shear strength of the joint was improved by decreasing the intermetallic compound (IMC) thickness; so the IMCs thickness must be controlled, because the formation of IMC leads to joint embrittlement at the interface. In conclusion, the addition of In and Fe can improve mechanical properties, such as shear strength, but the addition of In appears to be more effective for increasing the fracture toughness. The addition of Fe lowers the wetting angle and it can effectively improve the solder reliability, this improvement in shear behavior for the samples, which were reflowed on Cu substrate, is enhanced compared with the Ni substrate, but 0.6% Fe addition for the Cu substrate illustrates an decrease in fracture strain, because of abnormal growth of Cu6Sn5Whiskers in this case.

Similar content being viewed by others

References

A.D. Althouse., C.H. Turnquist, and W.A. Bowditch, Modern Welding. Goodheart-wilcox (2003)

I. Anderson, et al., Development of Eutectic and Near-eutectic Sn-Ag-Cu Solder Alloys for Lead-free Electronic Assemblies. Proceedings of 1PC Works’ 99 IPC, (2001) pp. 03–5

C.M.L. Wu et al., Properties of lead-free solder alloys with rare earth element additions. Mater. Sci. Eng. R. Rep. 44(1), 1–44 (2004)

R. Ciocci, M. Pecht and S. Ganesan, Lead-free electronics: overview. Lead-free Electron. (2006)

I. Anderson et al., Microstructural modifications and properties of Sn–Ag–Cu solder joints induced by alloying. J. Electron. Mater. 31(11), 1166–1174 (2002)

L. Gao et al., Effect of alloying elements on properties and microstructures of SnAgCu solders. Microelectron. Eng. 87(11), 2025–2034 (2010)

T. Laurila, V. Vuorinen, M. Paulasto-Kröckel, Impurity and alloying effects on interfacial reaction layers in Pb-free soldering. Mater. Sci. Eng. R. Rep. 68(1–2), 1–38 (2010)

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. Mater. Sci. Eng. R. Rep. 27(5–6), 95–141 (2000)

M. Erinç et al., Microstructural damage analysis of SnAgCu solder joints and an assessment on indentation procedures. J. Mater. Sci. Mater. Electron. 16(10), 693–700 (2005)

K.S. Kim, S.H. Huh, K. Suganuma, Effects of intermetallic compounds on properties of Sn–Ag–Cu lead-free soldered joints. J. Alloys Compd. 352(1–2), 226–236 (2003)

B.I. Noh et al., Effects of number of reflows on the mechanical and electrical properties of BGA package. Intermetallics 14(10–11), 1375–1378 (2006)

H. Ma, J. Suhling, A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 44(5), 1141–1158 (2009)

W. Yang, L. Felton, R. Messler, The effect of soldering process variables on the microstructure and mechanical properties of eutectic Sn–Ag/Cu solder joints. J. Electron. Mater. 24(10), 1465–1472 (1995)

B. Dompierre et al., Cyclic mechanical behaviour of Sn–3.0Ag–0.5Cu alloy under high temperature isothermal ageing. Mater. Sci. Eng. A. 528(13–14), 4812–4818 (2011)

Y.C. Chan, A.C.K. So, J.K.L. Lai, Growth kinetic studies of Cu–Sn intermetallic compound and its effect on shear strength of LCCC SMT solder joints. Mater. Sci. Eng. B. 55(1–2), 5–13 (1998)

J.H.L. Pang et al., Thermal cycling aging effects on Sn–Ag–Cu solder joint microstructure, IMC and strength. Thin Solid Films 462–463, 370–375 (2004)

P. Sebo et al., Effect of indium on the microstructure of the interface between Sn–3.13Ag–0.74Cu–In solder and Cu substrate. J. Alloys Compd. 480(2), 409–415 (2009)

S. Kang et al., Studies of the mechanical and electrical properties of lead-free solder joints. J. Electron. Mater. 31(11), 1292–1303 (2002)

D.H. DeSousa, L. Patry, S. Kang and D.-Y. Shih, In: 56th electronic components and technology conference (ECTC) (San Diego, 2006), p. 1454

Y.W. Wang et al., Effects of minor Fe, Co., and Ni additions on the reaction between SnAgCu solder and Cu. J. Alloys Compd. 478(1–2), 121–127 (2009)

T. Laurila et al., Effect of Ag, Fe, Au and Ni on the growth kinetics of Sn–Cu intermetallic compound layers. Microelectron. Reliab. 49(3), 242–247 (2009)

A. Sharif, Y.C. Chan, R.A. Islam, Effect of volume in interfacial reaction between eutectic Sn–Pb solder and Cu metallization in microelectronic packaging. Mater. Sci. Eng. B. 106(2), 120–125 (2004)

J. Hong, and M. Chason, X-ray diffraction study of copper-time intermetallic compounds on solder-coated PC boards. In: Electronic manufacturing technology symposium, 1988, ‘Design-to-manufacturing transfer cycle’. Fifth IEEE/CHMT International (1988)

G. Herrick, Method of Securing Metallic Members Together. (1988), Google Patents

K.S. Kim, S.H. Huh, K. Suganuma, Effects of fourth alloying additive on microstructures and tensile properties of Sn-Ag-Cu alloy and joints with Cu. Microelectron. Reliab. 43(2), 259–267 (2003)

K. Kanlayasiri, M. Mongkolwongrojn, T. Ariga, Influence of indium addition on characteristics of Sn-0.3Ag-0.7Cu solder alloy. J. Alloys Compd. 485(1–2), 225–230 (2009)

D.Q. Yu, J. Zhao, L. Wang, Improvement on the microstructure stability, mechanical and wetting properties of Sn–Ag–Cu lead-free solder with the addition of rare earth elements. J. Alloys Compd. 376(1–2), 170–175 (2004)

H. Fallahi, M.S. Nurulkamal, A. Fallahi, J. Abdullah, Effect of iron and indium on IMC formation and mechanical properties of lead-free solder. To be submitted to Material Science Engineering A (Feb 2012)

J.-W. Kim, S.-B. Jung, Reexamination of the solder ball shear test for evaluation of the mechanical joint strength. Int. J. Solids Struct. 43(7–8), 1928–1945 (2006)

L. Ty, and M. Velderrain, Calculated shear stress produced by silicone and epoxy thermal interface materials (TIMS) during thermal cycling. In: Electronics packaging technology conference, 2007. EPTC 2007. 9th. (2007)

Y.-D. Jeon et al., Studies of electroless nickel under bump metallurgy—solder interfacial reactions and their effects on flip chip solder joint reliability. J. Electron. Mater. 31(5), 520–528 (2002)

J. Young-Doo, L. Yong-Bin and C. Young-Sik, Thin electroless Cu/OSP on electroless Ni as a novel surface finish for flip chip solder joints. In: Electronic components and technology conference, 2006. Proceedings. 56th (2006)

B.S.S.C. Rao et al., Tensile deformation behavior of nano-sized Mo particles reinforced SnAgCu solders. Mater. Sci. Eng. A. 528(12), 4166–4172 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fallahi, H., Nurulakmal, M.S., Fallahi, A. et al. Modifying the mechanical properties of lead-free solder by adding iron and indium and using a lap joint test. J Mater Sci: Mater Electron 23, 1739–1749 (2012). https://doi.org/10.1007/s10854-012-0656-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0656-2