Abstract

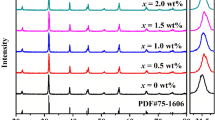

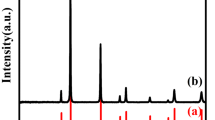

(1 − x) BaTiO3/xCuO ceramic pellets with x = 0, 0.2, 0.4, 0.6, and 0.8% respectively were prepared by the traditional solid-state reaction method. The effect of CuO doping on the microstructure and dielectric properties of BaTiO3 ceramics has been investigated. SEM and XRD results at room temperature show that the grain size grows with the increase of CuO content under the same sintering conditions and the crystal structure undergoes the mixed phases (pseudocubic/tetragonal) to tetragonal phase transition with the growth of grain size. Regular shape grains with average grain size ~2 μm are detectable in the specimens as CuO dopant content adds up to 0.8% and the crystal structure has completely changed into tetragonal phase. The permittivity increases markedly for CuO dopant content x = 0.2 ~ 0.4% and the dielectric loss decreases significantly after being doped by CuO and down to a minimum value for x = 0.8%. In addition, the permittivity and dielectric loss display a good stability in a broad frequency range comparing that of pure BaTiO3 ceramics.

Similar content being viewed by others

References

G.V. Lewis, C.R.A. Catlow, J. Casselton, J. Am. Ceram. Soc. 68, 555–561 (1985)

J.H. Han, D.Y. Kim, Acta Mater. 46, 2021–2028 (1998)

W.S. Cho, J. Phys. Chem. Solids 59, 659–666 (1998)

F.J. Gotor, L.A. Perez-Maqueda, J.M. Criado, J. Eur. Ceram. Soc. 23, 505–512 (2003)

Y. Liu, A.R. West, J. Eur. Ceram. Soc. 29, 3249–3257 (2009)

A. Shukla, R.N.P. Choudhary, A.K. Thakur, D.K. Pradhan, Physica B 405, 99–106 (2010)

R. Köerstein, L. Jäer, M. Zenkner, S.G. Ebbinghaus, Mater. Chem. Phys. 119, 118–122 (2010)

H.-P. Jeon, S.-K. Lee, S.-W. Kim, D.-K. Choi, Mater. Chem. Phys 94, 185–189 (2005)

G. Liu, R.D. Roseman, J. Mater. Sci. 34, 4439–4445 (1999)

F.-C. Yang, Ceram. Int 24, 341–346 (1998)

Y.C. Lee, W. Lu, S.H. Wang, C.H.W. Lin, Int. J. Miner. Metall. Mater. 16, 124–127 (2009)

S. Derling, Th. Müller, H.-P. Abicht, K.-H. Felgner, H.T. Langhammer, J. Mater. Sci. 36, 1425–1431 (2001)

C.-Y. Chen, W.-H. Tuan, J. Am. Ceram. Soc. 83, 2988–2992 (2000)

W. Luan, L. Gao, J. Guo, Ceram. Int 25, 727–729 (1999)

T.T. Fang, H.L. Hsieh, F.S. Shiau, J. Am. Ceram. Soc. 76, 1205–1211 (1993)

M.H. Frey, D.A. Payne, Phys. Rev. B 54, 3158–3168 (1996)

Acknowledgments

This work was supported by National Natural Science Foundation of China (Project No. 10875107), The Natural Science Foundation of Henan (Project No. 82300440080), The Basic Research Plan on Natural Science of the Education Department of Henan Province (Grant No. 2008A140014) and (Grant No. 2010B140016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, T., Yang, K., Xue, R. et al. The effect of CuO doping on the microstructures and dielectric properties of BaTiO3 ceramics. J Mater Sci: Mater Electron 22, 838–842 (2011). https://doi.org/10.1007/s10854-010-0222-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-010-0222-8