Abstract

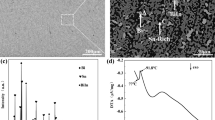

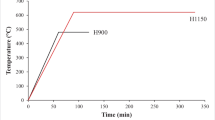

Charpy impact specimens of eutectic Sn37Pb and Sn3.8Ag0.7Cu solder joints with U-type notch were prepared to investigate the joint impact strength. The gap sizes of the butt joint were selected at 0.3 and 0.8 mm. Compared with the values of 0.3 mm joint gap, the impact absorbed energies of two solder joints were increased at the joint gap of 0.8 mm. The impact strengths of Sn37Pb joints were higher than those of Sn3.8Ag0.7Cu joints in both cases. From the macrographic observation of the fracture path, when the gap was 0.3 mm, the crack initiation of two solder joints located at the root of U-type notch then propagated along one interface of the joint. For the Sn37Pb joints, the fracture path was not changed at 0.8 mm gap size. However, the fracture path of Sn3.8Ag0.7Cu joint was totally changed and the fracture occurred not at the root of pre-U notch but from one side of the solder/Cu interfaces. From the micrographic observation, the crack of the Sn37Pb joints was concentrated on the Pb-rich layer in the vicinity of interfacial intermetallic (IMC) layer and the fracture morphology mainly appeared to be a ductile-like structure. Meanwhile, the fracture of Sn3.8Ag0.7Cu joints propagated along either the interface of IMC/solder or within the IMC layer and showed a brittle failure mode.

Similar content being viewed by others

References

K.N. Tu, A.M. Gusak, M. Li, J. Appl. Phys. 93(3), 1335–1353 (2003). doi:10.1063/1.1517165

Directive 2002/95/EC. The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment. The European Parliament and of the Council of the European Union, 27 January 2003

J.J. Sundelin, S.T. Nurmib, T.K. Lepistö, E.O. Ristolainen, Mater Sci Eng A 420, 55–62 (2006). doi:10.1016/j.msea.2006.01.065

N. Bonda, I. Noyan, IEEE Trans. Comp. Pack. Manufact. Technol. 19A, 208 (1996). doi:10.1109/95.506106

H. Lee, H. Lin, C. Lee, P. Chen, Mater. Sci. Eng. A 407, 36 (2005). doi:10.1016/j.msea.2005.07.049

M. Nishiura, A. Nakayama, S. Sakatani, Y. Kohara, K. Uenishi, K.F. Kobayashi, Mater. Trans. 43, 1802 (2002). doi:10.2320/matertrans.43.1802

W. Plumbridge, R. Matela, A. Westwater, Structural Integrity and Reliability in Electronics (Kluwer Academic Publishers, London, 2003)

C.M.L. Wu, M.L. Huang, Y.C. Chan, J.K.L. Lai, J. Electron. Mater. 29, 1015 (2000). doi:10.1007/s11664-000-0166-5

J. Glazer, J. Electron. Mater. 23, 693 (1994). doi:10.1007/BF02651361

J.H. Vincent, G. Humpston, GEC J. Res. 11, 76 (1994)

M. Date, T. Shoji, M. Fujiyoshi, K. Sato, K.N. Tu, Scripta Mater. 51, 641–645 (2004). doi:10.1016/j.scriptamat.2004.06.027

D. Suh, D.W. Kim, P. Liu, H. Kim, J.A. Weninger, C.M. Kumar et al., Mater. Sci. Eng. A 460–461, 595–603 (2007). doi:10.1016/j.msea.2007.01.145

W. Peng, M.E. Marques, J. Electron. Mater. 36, 1679–1690 (2007). doi:10.1007/s11664-007-0260-z

C.M. Kumar, Internal Report, Intel Corporation, 2006

Y.-S. Lai, P.-F. Yang, C.-L. Yeh, Microelectron. Reliab. 46, 645–650 (2006). doi:10.1016/j.microrel.2005.07.005

P. Zimprich, A. Betzwar-Kotas, G. Khatibi, B. Weiss, H. Ipser, J. Mater. Sci. Mater. Electron 19, 383–388 (2008). doi:10.1007/s10854-007-9349-7

P. Ratchev, B. Vandevelde, B. Verlinden, B. Allaert, D. Werkhoven, IEEE Trans. Comp. Pack. Technol. 30 (2007) 416–423

H.-T. Lee, M.-H. Chen, H.-M. Jao, T.-L. Liao. Mater. Sci. Eng. A 358, 134–141 (2003). doi:10.1016/S0921-5093(03)00277-6

Acknowledgements

The present work was performed under the financial support of the National 863 Hi-Tech Scheme (No. 2002AA322040) and the key program for the 11th five-Year Plan (No. 2006BAE03B02) of the China Department of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, N., Shi, Y., Xia, Z. et al. Investigation on impact strength of the as-soldered Sn37Pb and Sn3.8Ag0.7Cu solder joints. J Mater Sci: Mater Electron 20, 499–506 (2009). https://doi.org/10.1007/s10854-008-9757-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-008-9757-3