Abstract

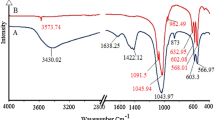

Novel hydroxyapatite-based hybrid materials with controlled porosity and good adhesion to silicon surfaces were designed as bio-package for MEMS with potential application for implants in the human body. These materials were prepared using synthetic Hydroxyapatite (HAp) powder with three different polymeric agglutinants. These porous materials have high ceramic content (up to 60 wt.% respect to resin) with a pore size between 100 and 350 microns and a pore volume fraction in the 25–60% range. These hybrid materials have high wearing resistance and hydrolytic stability. The samples were characterized mechanical and morphologically using XRD, SEM, densitometry, abrasion and mechanical tests.

Similar content being viewed by others

References

Z.W. Zhong, Z.F. Wang, Y.H. Tan, Chemical mechanical polishing of polymeric materials for MEMS applications. Microelectron. J. 37, 295–301 (2006)

S. Xiao, L. Che, X. Li, Y. Wang, A cost-effective flexible MEMS technique for temperature sensing. Microelectron. J. 38, 360–364 (2007)

B. Bhattacharyya, M. Malapati, J. Munda, A. Sarkar, Influence of tool vibration on machining performance in electrochemical micro-machining of copper. Int. J. Mach. Tools Manuf. 47, 335–342 (2007)

C. Lie, Y. Zhou, X.-Y. Gao, W. Ding, Y. Cao, Z.-M. Zhou, H. Choi, Fabrication of 3D MEMS toroidal micoinductor for high temperature application. Microelectron. J. 37, 1347–1351 (2006)

Y.I. Rozenberg, Y. Rosenberg, V. krylov, G. Belitsky, Y. Shacham-Diamand, Resin-bonded permanent magnetic films with uot-of-plane magnetization for MEMS applications. J. Magn. Magn. Mater. 305, 357–360 (2006)

D.-Y. Qiao, W.-Z. Yuan, X.-Y. Li, A two-beam method for extending the working range of electrostatic parallel-plate micro-actuators. J. Electrostat. 65, 256–262 (2007)

A. Sing, R. Mukherjee, K. Tuner, S. Shaw, MEMS implementation of axial and follower end forces. J. Sound Vib. 286, 637–644 (2005)

C. Roman, S. Mir, B. Charlot, Building an analogue fault simulation tool and its applications to MEMS. Microelectron. J. 34, 897–906 (2003)

P. Cooley, D. Wallace, B. Antohe, Applicatons of ink-jet printing technology to BioMEMS and microfluidic systems. J. Assoc. Lab. Automat. 7, 33–39 (2002)

M.C. Song, Z. Liu, M.J. Wang, T.M. Yu, D.Y. Zhao, Research on effects of injection process parameters on the molding process for ultra-thin wall plastic parts. J. Mater. Proce. Technol. 187, 668–667 (2007)

M. Barbic, Magnetic wires in MEMS and bio-medical applications. J. Magn. Magn. Mater. 249, 357–367 (2002)

G.S.P. Castle, Industrial applications of electrostatics: the past, present and future. J. Electrostat. 51, 1–7 (2001)

M.G. Alonso-Amigo, Polymer microfabrication for microarrays, microreactors and microfluidics. J. Assoc. Lab. Automat. 5, 96–101 (2000)

A. Cosijns, C. Vervaet, J. Luyten, S. Mullens, F. Siepmann, L. Van Hoorebeke, B. Masschaele, V. Cnudde, J.P. Remon, Porous hydroxyapatite tablets as carriers for low-dosed drugs. Eur. J. Pharm. Biopharm. (In Press), Corrected Proof, Available online 28 February 2007

T. Pichonat, B. Gauthier-Manuel, A new process s for the manufacturing of reproducible mesoporous silicon membranes. J. Membrane Sci. 280, 494–500 (2006)

V.J. P. Lim, K.A Khor, L. Fu, Hydroxyapatite—zirconia composite coatings via the plasma spraying process. J. Mater. Proce. Technol. 89, 491–496 (1999)

A. Kundu, J.H. Jang, H.R. Lee, S.-H. Kim, J.H. Gil, C.R. Jung, Y. Soo Oh, MEMS-based micro-fuel processor for application in a cell phone. J. Power Sour. 162, 572–578 (2006)

P.H.F. Caria, E.Y. Kawachi, C.A. Bertran, J.A. Camilli, Biological assessment of porous-implant hydroxyapatite combines with periosteal grafting in maxillary defects. J. Oral Maxill. Surg. 65, 847–854 (2007)

F. Tancret, J.-M. Bouler, J. Chamousset, L.-M. Minois, Modelling the mechanical properties of microporous and macroporous biphasic calcium phosphate bioceramics. J. Eur. Ceram. Soc. 26, 3647–3656 (2006)

I. Mobasherpour, M. Soulati Heshajin, A. Kazemzadeh, M. Zakeri, Synthesis of nanocrystalline hydroxyapatite by using precipitation method. J. Alloys Comp. 430, 330–333 (2007)

P.S. Uskokovic, C.Y. Tang, C.P. Tsui, N. Ignjatovic, D.P. Uskokovic, Micromechanical properties of a hydroxyapatite/poly-l-lactide biocomposite using nanoindentation and modulus mapping. J. Eur. Ceram. Soc. 27, 1559–1564 (2007)

C. Balázsi, F. Wéber, Z. kövér, E. Horváth, C. Németh, Preparation of calcium-phosphate bioceramics from natural resources. J. Eur. Ceram. Soc. 27, 1601–1606 (2007)

T. Katagiri, N. Takahashi, Regulatory mechanisms of osteoblast and osteoclast differentiation. Oral Dis. 8(3), 147–159 (2002)

J.P. Paul, Strength requirements for internal and external prostheses. J. Biomech. 32, 381–393 (1999)

M.H. Prado da Silva, A. Fernández Lemos, J.M. Fonte Ferreira, J. Domingos Santos, Mechanical characterization of porous glass reinforced hydroxyapatite ceramics–Bonelike. Mat. Res. 6(3), 321–325 (2003)

See for example: S. Susuki, E. Ando, Abrasion of thin films deposited onto glass by the Taber test. Thin Solid Films 340, 194–200 (1999)

E. Rivera-Muñoz, R. Velázquez, R. Rodríguez, Improvement in mechanical properties of hydroxiapatite objects with controlled porosity made by modified gelcasting process. Mater. Sci. Forum 426–432, 4489–4494 (2003)

Acknowledgments

The authors are in debt to Alicia del Real by her valuable help in SEM analysis and Maribel Presa for the determination of the mechanical properties.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodriguez, R., Estevez, M., Vargas, S. et al. Hap-based porous material with potential application as bio-packages for MEMS. J Mater Sci: Mater Electron 19, 646–652 (2008). https://doi.org/10.1007/s10854-007-9413-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-007-9413-3