Abstract

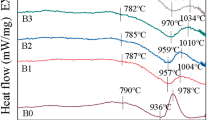

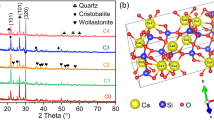

The influences of addition of ZnO on sintering, crystallization behavior and properties of cordierite-based glass-ceramics were investigated. Results show that with increasing ZnO content, the batch melting temperature, glass transition temperature and crystallization temperature all decrease. Addition of ZnO can greatly improve the sinterability of the glass powders and alter the type of the crystalline phases. Addition of 1.5 wt% ZnO seems to be reasonable. Thermal expansion coefficients (TCEs) of samples increase with increasing ZnO contents. The density was found to be an important factor affecting the dielectric loss of the samples. Dielectric constant and TCEs of the sintered bulk samples were found to depend on their relative densities and crystalline phases. The samples doped with 1.5–3.0 wt% ZnO sintered at 950 °C has a low dielectric constant (5.0–5.2), a low dielectric loss (≤0.0018) and a low thermal expansion coefficient (3.6–4.8 × 10−6 K−1), which are promising electronic packaging materials.

Similar content being viewed by others

References

A.H. Kumar, P.W. McMillan, R.R. Tummala, US Pat. 4301324, November 1981

S.H. Knickerbocker, A.H. Kumar, L.W. Herron, Am. Ceram. Soc. Bull. 72, 90 (1993)

R.R. Tummala, J. Am. Ceram. Soc. 74, 905 (1991)

Y. Shimade, K. Utsumi, M. Suzuki, H. Takamizawa, M. Nitta, T. Watari, IEEE Trans. Compon. Hybrids Manuf. Technol. 6, 382 (1983)

D.R. Bridged Holland, P.W. McMillan, Glass Technol. 26, 286 (1985)

H.K. Sarah, H.K. Ananda, L.W. Herron, Am. Ceram. Soc. Bull. 72, 90 (1993)

M. Okuyama, T. Fukui, C. Sakurai, J. Mater. Sci. 28, 4465 (1993)

Mei S., Yang J., Ferreira J.M.F, Meter. Lett. 47, 205 (2001)

W. Zdaniewski, J. Am. Ceram. Soc. 58, 163 (1975)

S.B. Sohn, S.Y. Choi, J. Non-Cryst. Solids 282, 221 (2001)

Y. Hu, H.T. Tsai, J. Mater. Sci. 36, 123 (2001)

C.F. Yang, C.M. Cheng, Ceram. Int. 25, 383 (1999)

G.H. Chen, X.Y. Liu, J. Mater. Sci: Mater. Elelc. 15, 595 (2004)

C. Wang, W. Xu, J. Non-Cryst. Solids 80, 237 (1986)

A.A. Omar, A.W.A. El-Shennavi, A.R. El-Ghannam, J. Mater. Sci. 26, 6049 (1991)

Northwest Institute of Light Industry, Glass Technology (in Chinese) (China Light Industry Press, Beijing, 1982)

J.H. Jean, T.K. Gupta, J. Am. Ceram. Soc. 76, 2010 (1993)

A.A. EI-Kheshen, Br. Ceram. Trans. 102, 205 (2003)

L.S. Chen, S.L. Fu, Jpn. J. Appl. Phys. 31, 3917 (1992)

S.J. Penn, N.M. Alford, A. Templeton, J. Am. Ceram. Soc. 80, 1885 (1997)

L.R. Pinckney, J. Non-Cryst. Solids 255, 171 (1999)

Acknowledgement

This work was supported by the Natural Science Foundation of Guangxi Province, China, under contract No.: 0339066.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Gh. Effect of ZnO addition on properties of cordierite-based glass-ceramics. J Mater Sci: Mater Electron 18, 1253–1257 (2007). https://doi.org/10.1007/s10854-007-9283-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-007-9283-8