Abstract

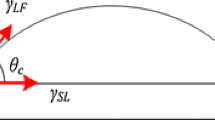

The research in lead(Pb)-free solder alloy has been a popular topic in recent years, and has led to commercially available Pb-free alloys. Further research in certain properties to improve aspects such as manufacturability and long term reliability in many Pb-free alloys are currently undertaken. It was found by researchers that popular Pb-free solders such as Sn–Ag, Sn–Cu, Sn–Zn and Sn–Ag–Cu had improved their properties by doping with trace amounts of rare earth (RE) elements. The improvements include better wettability, creep strength and tensile strength. In particular, the increase in creep rupture time in Sn–Ag–Cu–RE was 7 times, when the RE elements were primarily Ce and La. Apart from these studies, other studies have also shown that the addition of RE elements to existing Pb-free could make it solderable to substrates such as semiconductors and optical materials. This paper summarizes the effect of RE elements on the microstructure, mechanical properties and wetting behavior of certain Pb-free solder alloys. It also demonstrates that the addition of RE elements would improve the reliability of the interconnections in electronic packaging. For example, when Pb-free-RE alloys were used as solder balls in a ball grid array (BGA) package, the intermetallic compound layer thickness and the amount of interfacial reaction were reduced.

Similar content being viewed by others

References

K.N. Tu, K. Zeng, Mater. Sci. Eng. R 34(1), 1 (2001)

International Printed Circuit Association Solder Products Value Council, “White Paper: IPC-SPVC-WP-006 Round Robin Testing and Analysis, Lead Free Alloys: Tin, Silver, Copper”, 12 August 03

M. Abtew, G. Selvaduray, Mater. Sci. Eng. R 27(5/6), 95 (2000)

Z.G. Yu, M.B. Chen, in Rare earth elements and their applications (Metallurgical Industry Press, China, 1995), pp. 138

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, J. Mater. Res. 31(9), 3146 (2002)

H. Mavoori, A.G. Ramirez, S. Jin, Appl. Phys. Lett. 78(19), 2976 (2001)

C.M.T. Law, PhD Thesis on “Reliability and Interfacial Reaction of Lead-free Solder Alloys Doped with Rare Earth Elements”, Department of Physics and Materials Science, City University of Hong Kong (2004)

Z.G. Chen, Y.W. Shi, Z.D. Xia, Y.F. Yan, J. Electron. Mater. 32(4), 235 (2003)

J. Glazer, J. Electron. Mater. 23(8), 693 (1994)

K. Suganuma, Curr. opin. solid mater. sci. 5, 55 (2001)

C.M.T. Law, C.M.L. Wu, D.Q. Yu, L. Wang, J.K.L. Lai, J. Electron. Mater. 35(1), 89 (2006)

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, J. Electron. Mater. 31(9), 921 (2002)

K. Suganuma, K. Niiara, J. Mater. Res. 13(10), 2859 (1998)

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, J. Electron. Mater. 31(9), 928 (2002)

H. Baker et al., (ed.), Alloy phase diagrams, ASM Handbook 3, Materials Park, OH, 1990, pp. 137

H. Baker et al., (ed.), Alloy phase diagrams, ASM Handbook 3, Materials Park, OH, 1990, pp. 275

X. Ma, F. Yoshida, Mater. Lett. 56(4), 441 (2002)

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, J. Electron. Mater. 32(29), 63 (2003)

Z.D. Xia, Z.G. Chen, Y.W. Shi, N. Mu, N. Sun, J. Electron. Mater. 31(6), 564 (2002)

Z.G. Chen, Y.W. Shi, Z.D. Xia, Y.F. Yan, J. Electron. Mater. 31(10), 1122 (2002)

E. Gebhardt, G. Petzow, 50, 597 (1959)

Q.J. Zhai, S.K. Guan, Q.Y. Shang, Alloy Thermo-Mechanism: Theory and Application (Metallurgy Industry Press, Beijing, 1999)

D.Q. Yu, J. Zhao, L. Wang, J. Alloys Compd. 376, 170 (2004)

R.J. Mccabe, M.E. Fine, JOM 52(6), 33 (2000)

M.L. Huang, L. Wang, C.M.L. Wu, J. Mater. Res. 17(11), 2897 (2002)

V.I. Igoshev, J.I. Kleiman, D. Shanguan, C. Lock, S. Wong, J. Electron. Mater. 27(12), 1367 (1998)

W.C. Oliver, W.D. Nix, Acta Metall. 30(7), 1335 (1982)

Z.G. Chen, Y.W. Shi, Z.D. Xia, J. Electron. Mater. 33(9), 964 (2004)

P.T. Vianco, A.C. Claghorn, Solder. Surf. Mt. Technol. 8(3), 12 (1996)

C.C. Tu, M.E. Natishan, Solder. Surf. Mt. Technol. 12(2), 10 (2000)

P.T. Vianco, D.R. Frear, JOM, 23(7), 14 (1993)

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, Materials Science and Engineering Reports, R44/1 pp. 1, April 2004

H.C.B Woo, in MSc Thesis of “Solderability & Microstructure of Lead-free Solder in Leadframe Packaging”, Department of Physics and Materials Science, City University of Hong Kong (2005)

P. Nash, A. Nash, H. Baker et al., (ed.), Alloy phase diagrams, ASM Handbook 3, Materials Park, OH, 1990, Section 2, p. 32

IPC, IPC Roadmap on Lead-free soldering, 3rd draft, (2003)

D.R. Frear, JOM 48(5), 49 (1996)

J.K. Shang, D. Yao, J. Electron. Packag. 118(3), 170 (1996)

C.M.T. Law, C.M.L. Wu, D.Q. Yu, K.Y. Lee, M. Li, in Proceedings of the Materials Science & Technology 2003 “Solderability and Growth of Intermetallic Compounds upon Aging of Sn–Ag–RE and Sn–Cu–RE Lead-free Alloys” Conf., Chicago, 9–12 Nov (2003)

D.R. Flanders, E.G. Jacobs, R.F. Pinizzotto, J. Electron. Mater. 26, 883 (1997)

S. Choi, T.R. Bieler, J.P. Lucas, K.N. Subramanian, J. Electron. Mater. 28, 1209 (1999)

K.N. Tu, R.D. Thompson, Acta Metall. 30, 947 (1982)

K.N. Tu, Phys. Rev. B 49, 2030 (1994)

H. Mavoori, A.G. Ramirez, S. Jin, J. Electron. Mater. 31(11), 1160 (2002)

A.G. Ramirez, H. Mavoori, S. Jin, Appl. Phys. Lett. 80(3), 398 (2002)

C.M.T. Law, C.M.L. Wu, in Proceedings of the 6th IEEE CPMT Conference on High Density Microsystem Design and Packaging and Component Failure Analysis, 30 June–3 July 2004, Shanghai, pp. 60–65

C.M.L. Wu, C.M.T. Law, in Proceedings of the “Microstructure and Shear Strength of Aged Sn–Cu–RE BGA Solder Bumps”, Conf. Materials Science & Technology, Chicago, 9–12 Nov, (2003)

C.M.T. Law, C.M.L. Wu, D.Q. Yu, M. Li, D.Z. Chi, IEEE Trans. Adv. Pack. 28(2), 252 (2005)

A. Zribi, A. Clark, L. Zavalij, P. Borgesen, E.J. Cotts, J. Electron. Mater. 30, 1157 (2001)

W.T. Chen, C.E. Ho, C.R. Kao, J. Mater. Res. 17, 263 (2002)

C.E. Ho, R.Y. Tsai, Y.L. Lin, C.R. Kao, J. Electron. Mater. 31, 584 (2002)

B. Li, Y. Shi, Y. Lei, F. Guo, Z. Xia, B. Zong, J. Electron. Mater. 34, 217 (2005)

Acknowledgements

The work described in this report was fully supported by a grant from the Research Grants Council of the Hong Kong Special Administrative Region, P. R. China [Project No. CityU 1026/04P].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, C.M.L., Wong, Y.W. Rare-earth additions to lead-free electronic solders. J Mater Sci: Mater Electron 18, 77–91 (2007). https://doi.org/10.1007/s10854-006-9022-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-006-9022-6