Abstract

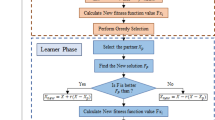

In the realm of welding production, optimizing parameters for enhanced quality and efficiency remains a challenge. This study introduces a novel approach using ABAQUS for simulating the thermal–mechanical behavior in T-shaped double-sided welded joints of Q345 steel. Initial simulations were experimentally validated. A range of welding parameters was then established, and the “Unifrnd” function helped sample within this range. This study considers eight welding parameters as input variables for an artificial neural network (ANN), trained to predict residual stress and deformation. Optimization algorithms NSGA-II (non-dominated sorting genetic algorithm-II) and MOPSO (multi-objective particle swarm optimization) algorithm were employed to refine the ANN's outputs. Notably, the Pareto front revealed an optimal balance between minimizing residual stress and deformation. While single optimization achieved up to 5.12% reduction in residual stress and over 50% in deformations, the tri-objective optimization resulted in a more balanced reduction (about 1.88% in residual stress and over 20% in deformations). This highlights the need for parameters weighting in decision-making. The findings demonstrate the effectiveness of integrating ANN with optimization algorithms for welding parameter optimization, with implications for improved welding practices.

Graphical abstract

Similar content being viewed by others

Data and code availability

Data and code will be available upon request.

References

Pan B, Zhang H, Liu S et al (2023) Dynamic responses of semi-flexible pavements used for the autonomous rail rapid transit. Appl Sci Basel 13:3673. https://doi.org/10.3390/app13063673

Yuan G, Shu Q, Huang Z et al (2016) An experimental investigation of properties of Q345 steel pipe at elevated temperatures. J Construct Steel Res 118:41–48. https://doi.org/10.1016/j.jcsr.2015.10.022

Rajesh PV, Gupta KK, Čep R et al (2022) Optimizing friction stir welding of dissimilar grades of aluminum alloy using WASPAS. Materials 15:1715. https://doi.org/10.3390/ma15051715

Xie W, Tu H, Nian K et al (2024) Microstructure and mechanical properties of Flexible Ring Mode laser welded 304 stainless steel. Opt Laser Technol 174:110563. https://doi.org/10.1016/j.optlastec.2024.110563

Zhao S, Yu G, He X et al (2012) Microstructural and mechanical characteristics of laser welding of Ti6Al4V and lead metal. J Mater Process Technol 212:1520–1527. https://doi.org/10.1016/j.jmatprotec.2012.02.014

Chen S, Wu Y, Li Y et al (2020) Study on 2219 Al-Cu alloy T-joint used dual laser beam bilateral synchronous welding: parameters optimization based on the simulation of temperature field and residual stress. Opt Laser Technol 132:106481. https://doi.org/10.1016/j.optlastec.2020.106481

Xia P, Xiong L, Hu Y et al (2023) Effect of laser oscillation and beam incident angle on porosity in double-sided filler welding of 2219 aluminum alloy T joint. Opt Laser Technol 166:109581. https://doi.org/10.1016/j.optlastec.2023.109581

Zhang H, Wang C, Lin S (2021) Molten pool behaviors in double-sided pulsed gmaw of t-joint: a numerical study. Metals 11:1594. https://doi.org/10.3390/met11101594

Jie Y, Zhang J-m, Cao S-f et al (2019) Effect of welding sequence on residual stress and deformation of 6061–T6 aluminium alloy automobile component. Trans Nonferrous Met Soc China 29:287–295. https://doi.org/10.1016/S1003-6326(19)64938-1

Knoedel P, Gkatzogiannis S, Ummenhofer T (2017) Practical aspects of welding residual stress simulation. J Constr Steel Res 132:83–96. https://doi.org/10.1016/j.jcsr.2017.01.010

Liu S, Wu Z, Zhou W et al (2023) A review of welding simulation methods for large components. Prog Nat Sci. https://doi.org/10.1016/j.pnsc.2023.12.004

She L, Wei Y, Wang S et al (2018) Welding parameter optimization of electron beam welded GH4169 superalloy based on orthogonal experiment and numerical simulation. Mater Res Exp 6:026567. https://doi.org/10.1088/2053-1591/aaf18f

Sada SO (2020) The use of multi-objective genetic algorithm (MOGA) in optimizing and predicting weld quality. Cogent Eng. 7:1741310. https://doi.org/10.1080/23311916.2020.1741310

Venkata Rao K, Parimi S, Suvarna Raju L et al (2022) Modelling and optimization of weld bead geometry in robotic gas metal arc-based additive manufacturing using machine learning, finite-element modelling and graph theory and matrix approach. Soft Comput. https://doi.org/10.1007/s00500-022-06749-x

Kelly MR, Schmid SR, Adams DC et al (2019) Experimental investigation of linear friction welding of AISI 1020 steel with pre-heating. J Manuf Process 39:26–39. https://doi.org/10.1016/j.jmapro.2019.01.038

Huang Y, Hu Y, Zhang M et al (2022) Multi-objective optimization of process parameters in laser cladding CoCrCuFeNi high-entropy alloy coating. J Therm Spray Technol. 31:1985–2000. https://doi.org/10.1007/s11666-022-01408-x

Wu C, Wang C, Kim J-W (2022) Welding sequence optimization to reduce welding distortion based on coupled artificial neural network and swarm intelligence algorithm. Eng Appl Artif Intell 114:105142. https://doi.org/10.1016/j.engappai.2022.105142

Ansaripour N, Heidari A, Eftekhari SA (2020) Multi-objective optimization of residual stresses and distortion in submerged arc welding process using Genetic Algorithm and Harmony Search. Proc Inst Mech Eng Part C-J Eng Mech Eng Sci 234:862–871. https://doi.org/10.1177/0954406219885977

Shao Q, Tan F, Li K et al (2021) Multi-objective optimization of MIG welding and preheat parameters for 6061–T6 Al alloy T-joints using artificial neural networks based on FEM. Coatings 11:998. https://doi.org/10.3390/coatings11080998

Li Y, Xiong M, He Y et al (2022) Multi-objective optimization of laser welding process parameters: The trade-offs between energy consumption and welding quality. Opt Laser Technol 149:107861. https://doi.org/10.1016/j.optlastec.2022.107861

Zhou K, Wang G, Ren B et al (2023) Process optimization of aluminum/steel resistance spot welding based on dynamic resistance analysis. J Mater Sci 58:17908–17929. https://doi.org/10.1007/s10853-023-09157-0

Tian L, Luo Y, Wang Y et al (2014) Prediction of transverse and angular distortions of gas tungsten arc bead-on-plate welding using artificial neural network. Mater. Des. 54:458–472. https://doi.org/10.1016/j.matdes.2013.08.082

Joshi M, Ghadai RK, Madhu S et al (2021) Comparison of NSGA-II, MOALO and MODA for multi-objective optimization of micro-machining processes. Materials 14:5109. https://doi.org/10.3390/ma14175109

Pereira JLJ, Oliver GA, Francisco MB et al (2022) A review of multi-objective optimization: methods and algorithms in mechanical engineering problems. Arch Comput Method Eng 29:2285–2308. https://doi.org/10.1007/s11831-021-09663-x

Hammad A, Churiaque C, Sánchez-Amaya JM et al (2021) Experimental and numerical investigation of hybrid laser arc welding process and the influence of welding sequence on the manufacture of stiffened flat panels. J Manuf Process 61:527–538. https://doi.org/10.1016/j.jmapro.2020.11.040

Bagheri B, Abbasi M, Abdolahzadeh A et al (2020) Numerical analysis of cooling and joining speed effects on friction stir welding by smoothed particle hydrodynamics (SPH). Arch Appl Mech 90:2275–2296. https://doi.org/10.1007/s00419-020-01720-4

Liu F, Tao C, Dong Z et al (2021) Prediction of welding residual stress and deformation in electro-gas welding using artificial neural network. Mater Today Commun 29:102786. https://doi.org/10.1016/j.mtcomm.2021.102786

Lin R, Feng B, Liu L et al (2023) Effect of welding inclination angle on strain distribution of X80 pipeline steel welded joint in mountain environment. J Mater Eng Perform. https://doi.org/10.1007/s11665-023-08805-5

Wang Y, Feng G, Pu X et al (2021) Influence of welding sequence on residual stress distribution and deformation in Q345 steel H-section butt-welded joint. J Mater Res Technol JMRT 13:144–153. https://doi.org/10.1016/j.jmrt.2021.04.059

Hu L, Luo W, Lu F et al (2024) FE analysis of residual stress and welding deformation of a low-alloy UHS quenched steel fillet joint. J Mater Res Technol JMRT 29:5693–5712. https://doi.org/10.1016/j.jmrt.2024.02.212

Perić M, Tonković Z, Rodić A et al (2014) Numerical analysis and experimental investigation of welding residual stresses and distortions in a T-joint fillet weld. Mater Des 53:1052–1063. https://doi.org/10.1016/j.matdes.2013.08.011

Gao X, Shao Y, Chen C et al (2023) Investigation on residual stress of EQ56 high strength steel butt weld. Ocean Eng 279:114405. https://doi.org/10.1016/j.oceaneng.2023.114405

Zhao S, Li Y, You H et al (2023) Finite element simulation of multi-pass welding of AA6061-T6 plate-sleeve: effect of different yield strengths of weld and base metals. Trans Indian Inst Met 76:1915–1927. https://doi.org/10.1007/s12666-023-02902-8

Zubairuddin M, Albert S, Vasudevan M et al (2017) Numerical simulation of multi-pass GTA welding of grade 91 steel. J Manuf Process 27:87–97. https://doi.org/10.1016/j.jmapro.2017.04.031

Flint T, Francis J, Smith M et al (2017) Extension of the double-ellipsoidal heat source model to narrow-groove and keyhole weld configurations. J Mater Process Technol 246:123–135. https://doi.org/10.1016/j.jmatprotec.2017.02.002

Sun J, Dilger K (2023) Influence of preheating on residual stresses in ultra-high strength steel welded components. J Mater Res Technol JMRT. https://doi.org/10.1016/j.jmrt.2023.06.181

Kim K-H, Bang H-S, Ro C-S et al (2017) Influence of preheating source on mechanical properties and welding residual stress characteristics in ultra thin ferritic stainless steel hybrid friction stir welded joints. Int J Precis Eng Anuf Gr Tech. 4:393–400. https://doi.org/10.1007/s40684-017-0044-8

Allahkarami M, Hanan JC (2014) Three-dimensional x-ray diffraction detection and visualization. Meas Sci Technol 25:055604. https://doi.org/10.1088/0957-0233/25/5/055604

Li Y, Lee TH, Banu M et al (2020) An integrated process-performance model of ultrasonic composite welding based on finite element and artificial neural network. J Manuf Process 56:1374–1380. https://doi.org/10.1016/j.jmapro.2020.04.033

Pareek C, Tewari V, Machavaram R (2023) Multi-objective optimization of seeding performance of a pneumatic precision seed metering device using integrated ANN-MOPSO approach. Eng Appl Artif Intell 117:105559. https://doi.org/10.1016/j.engappai.2022.105559

Damavandi MD, Mousavi SM, Safikhani H (2017) Pareto optimal design of swirl cooling chambers with tangential injection using CFD, GMDH-type of ANN and NSGA-II algorithm. Opt Laser Technol 122:102–114. https://doi.org/10.1016/j.ijthermalsci.2017.08.016

Muránsky O, Smith MC, Bendeich PJ, et al. (2012) Comprehensive numerical analysis of a three-pass bead-in-slot weld and its critical validation using neutron and synchrotron diffraction residual stress measurements. Int J Solids Struct 49: 1045–1062. https://doi.org/10.1016/j.ijsolstr.2011.07.006

Zhu K, Mu L, Yu R et al (2023) Probabilistic modelling of surface drift prediction in marine disasters based on the NN–GA and ARMA model. Ocean Eng 281:114804. https://doi.org/10.1016/j.oceaneng.2023.114804

Tazik M, Dehghani MH, Yaghmaeian K et al (2023) 4-Chlorophenol adsorption from water solutions by activated carbon functionalized with amine groups: response surface method and artificial neural networks. Sci Rep 13:7831. https://doi.org/10.1038/s41598-023-35117-4

Hosseini S, Abdollah-Zadeh A, Naffakh-Moosavy H et al (2019) Elimination of hot cracking in the electron beam welding of AA2024-T351 by controlling the welding speed and heat input. J Manuf Process 46:147–158. https://doi.org/10.1016/j.jmapro.2019.09.003

Villani G (2021) A neural network approach to value R&D compound American exchange option. Comput Econ. https://doi.org/10.1007/s10614-021-10150-5

Lou Y, Wu R, Li J et al (2023) Classification-based prediction of network connectivity robustness. Neural Netw 157:136–146. https://doi.org/10.1016/j.neunet.2022.10.013

Ajbar W, Parrales A, Cruz-Jacobo U et al (2021) The multivariable inverse artificial neural network combined with GA and PSO to improve the performance of solar parabolic trough collector. Appl Therm Eng 189:116651. https://doi.org/10.1016/j.applthermaleng.2021.116651

RezaeiAshtiani H, Shayanpoor A (2021) Hot deformation characterization of pure aluminum using artificial neural network (ANN) and processing map considering initial grain size. Met Mater Int. https://doi.org/10.1007/s12540-020-00943-y

Dey K, Kalita K, Chakraborty S (2023) Prediction performance analysis of neural network models for an electrical discharge turning process. Int J Interact Des Manuf IJIDeM 17:827–845. https://doi.org/10.1007/s12008-022-01003-y

Behera RR, Ghadai RK, Kalita K et al (2016) Simultaneous prediction of delamination and surface roughness in drilling GFRP composite using ANN. Int J Plast 20:424–450. https://doi.org/10.1007/s12588-016-9163-2

Qin L, Huang W, Du Y et al (2020) Correction to: genetic algorithm-based inverse design of elastic gridshells. Struct Multidiscip Optim 62:2709–2710. https://doi.org/10.1007/s00158-020-02711-3

El Mrabti I, Touache A, ElHakimi A et al (2021) Springback optimization of deep drawing process based on FEM-ANN-PSO strategy. Struct Multidiscip Optim 64:321–333. https://doi.org/10.1007/s00158-021-02861-y

Wang J, Chen X, Yang L (2022) Reliability-based multi-objective optimization incorporating process–property–performance relationship of double-pulse MIG welding using hybrid optimization strategy. Struct Multidiscip Optim 65:148. https://doi.org/10.1007/s00158-021-03103-x

Darvish Damavandi M, Safikhani H, Yahyaabadi M (2017) Multi-objective optimization of asymmetric v-shaped ribs in a cooling channel using CFD, artificial neural networks and genetic algorithms. J Braz Soc Mech Sci Eng 39:2319–2329. https://doi.org/10.1007/s40430-016-0698-0

Hajihassani M, Jahed Armaghani D, Kalatehjari R (2018) Applications of particle swarm optimization in geotechnical engineering: a comprehensive review. Geotech Geol Eng 36:705–722. https://doi.org/10.1007/s10706-017-0356-z

Shivaie M, Sepasian MS, Sheikh-El-Eslami MK (2013) Multi-objective transmission expansion planning based on reliability and market considering phase shifter transformers by fuzzy-genetic algorithm. Int Trans Electr Energy Syst 23:1468–1489. https://doi.org/10.1002/etep.1672

Faghiri S, Poureslami P, Partovi Aria H et al (2023) Multi-objective optimization of multiple droplet impacts on a molten PCM using NSGA-II optimizer and artificial neural network. Sci Rep 13:10543. https://doi.org/10.1038/s41598-023-37712-x

Acknowledgements

This study was supported by Jilin Provincial Department of Science and Technology (Grant No. 20170204071GX).

Author information

Authors and Affiliations

Contributions

Yunjie Tan contributed to writing—original draft, conceptualization, investigation, software, validation, and methodology. Guoren Zhu and Bosen Chai contributed to methodology, validation, investigation, and revision. Fengjun Tian contributed to validation, investigation, and revision. Zhonghao Zhao contributed to software, validation, investigation, and revision.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no financial or personal relationships that could have influenced the work presented in this paper.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tan, Y., Zhu, G., Tian, F. et al. Multi-objective optimization of T-shaped bilateral laser welding parameters based on NSGA-II and MOPSO. J Mater Sci 59, 9547–9573 (2024). https://doi.org/10.1007/s10853-024-09727-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09727-w