Abstract

The remediation of water from organic pollutants, such as dyes and related compounds and the reuse of discarded glasses, represents fundamental challenges in highly industrialized countries. Porous glass microspheres have been proposed as efficient adsorbents in wastewater treatment, but their real application is problematic, especially from the perspective of their reuse and recycling. For the first time, the present paper describes the process of preparation and use of highly porous bodies with a specific surface area of nearly 20 m2/g fabricated from alkali activated glass microspheres and applicable for the removal of methylene blue as a model organic dye from wastewater. Alkali activation is applied both as an intermediate step (using 9 M KOH) for the conversion of waste glass into porous microspheres by flame spheroidization process, and as a final step (using 2.5 M NaOH), facilitating low temperature consolidation of the microspheres, and their transformation into porous structures. The experimental adsorption capacity of porous glass microspheres pellet was 122 mg/g. The high correlation coefficient indicates the applicability of Langmuir isotherm adsorption model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Glass microspheres are spherical particles which typically range from 1 to 200 μm in diameter and can be classified into three categories: solid, hollow and porous [1]. Solid microspheres are usually fully dense; hollow microspheres feature a relatively large void surrounded by thin solid walls and finally, porous microspheres exhibit a multitude of holes in the walls, so that the porosity is completely open [2].

Vast amounts of glass waste are generated in industrial sectors around the world. Most of this glass waste is landfilled. Landfilling of unrecycled glass is one of the main reasons for ecological problems. The fabrication of one ton of glass from raw materials results in 0.39 metric tons of CO2: recycling glass waste can decrease greenhouse gas emissions from glass production by around 37% [3]. Reusing turns into ‘upcycling’ if waste glass-derived articles have a high added value. In this respect, transforming glass waste into porous glass microspheres represents an interesting option with high added value [4].

The value of waste glass-derived materials relies on the application. Glass microspheres present unique features such as high surface area, reactivity and hydrophilicity, which makes them interesting for purification technologies and environmental remediation [5]. In the latter field, the remediation of waters from organic contamination is of utmost importance. Synthetic dyes are released into wastewater from different industrial outlets, such as food coloring, cosmetics, leather, textile industries, etc. Most of these industries utilize large quantities of dyes and release them as contaminants into the environment as wastewater effluents. The industrial dyes and dyes-related compounds have a profound impact on aquatic life and ecosystems [6, 7]. They are extremely toxic to microbial populations and often carcinogenic, requiring thorough removal from wastewater [8]. Methylene blue, used in a wide range of textile and printing materials [9], is particularly difficult to be extracted from water, due to the complex aromatic ring in its structure [10].

In general, dyes are categorized as anionic, cationic and neutral species, and their remediation by adsorption and/or photodegradation processes [11] are studied extensively [12]. Adsorption is considered an affordable and reproducible process for the removal of water contaminants. It is a surface phenomenon utilizing, in addition to chemical interactions, mainly surface physical interactions. A significant benefit of the adsorption is that it does not require any additional chemicals or UV radiation and is therefore recommended in water purification technologies [7, 13]. When a solution containing an adsorbable solute comes into contact with a porous solid structure (adsorbent), liquid–solid attractive intermolecular forces lead to the solute being accumulated at the solid surface.

Currently established approaches of sorbent synthesis, such as sol gel, spray drying and solvent evaporation and polymerization, are often time-consuming and sometimes require a toxic solvent. The current work is for the first time dedicated to the exploitation of a simple, double alkali activation approach applied to waste glass from the manufacturing of insulating glass fibers, to produce highly porous sorbent materials. As reported recently [4], suspensions of fine glass powders in alkaline solutions undergo gelation at nearly room temperature, owing to the partial dissolution of glass and condensation of reaction products. Powders from crushed dried suspensions are easily converted into hollow glass microspheres by flame synthesis: droplets of softened glass are foamed by the gases released by the decomposition of hydrated compounds responsible for hardening. We will show that the activation/gelation approach can be duplicated for the easy manufacturing of pellets: the binding of glass microspheres is achieved without compromising the adsorption capability.

Materials and methods

Fabrication of porous glass microspheres

Residues from the production of fiber glass were supplied by Johns Manville (Trnava, Slovakia). They consisted of calcium alumino-boro-silicate glass, with the composition of (55.2 SiO2, 23.0 CaO, 13.6 Al2O3, 5.1 B2O3, 0.4 Na2O, 0.6 K2O, 0.9 MgO, 0.4 TiO2, 0.2 Fe2O3 and 0.01 SO3 in wt%.), as determined by X-ray fluorescence (XRF) analysis using a wavelength dispersive spectrometer (S8 TIGER 4 kW, Bruker, Billerica, MA, USA) equipped with an X-ray tube with Rh anode (30 kV and 100 mA). The fiber glass was crushed and sieved below 75 μm. Afterward, the fine powder was axially pressed into a pellet which was then used for chemical analysis.

For the alkali activation, the glass fiber waste was first crushed and sieved below 40 µm. In the subsequent step, the glass powder was suspended in an aqueous solution (9 M) of KOH (Penta, Bratislava, Slovakia), at a solid loading of 65 wt%, under mechanical stirring (1 h at 500 rpm). The formed gel was poured into plastic containers (diameter 10 mm) and left to dry at 75 °C for one day. The consolidation procedure was based on the results of our previous research [4]. The hardened dry gel was crushed into fine powder and was characterized by X-ray powder diffraction to analyze the phase composition.

The sieved alkali activated powders (40–80 µm) were fed into a methane-oxygen flame at the pressure of 1.6 hPa, using O2 as a carrier gas. Spherical molten droplets formed in a flame with estimated maximum temperatures in the range of 1500–1600 °C were quenched by deionized water to form porous glass microspheres. The produced microspheres were collected in a sedimentation tank and then filtrated by a ceramic filter with the pore size < 3 μm.

Fabrication of sorbent pellets

The obtained glass microspheres were used for the fabrication of sorbent pellets applicable as stationary filters, by applying a second alkali activation in a 2.5 M NaOH solution (Penta, Bratislava, Slovakia). The same solid loading of 65 wt% was used. The suspension of glass was mixed in polystyrene (PS) cylindrical tube (10 mm diameter) and dried at 75 °C for 24 h, before demolding. The obtained pellets were immersed in a methylene blue aqueous solution with the initial concentrations of 50–500 ppm for different contact times (0.5–12 h). The removal efficiency of methylene blue was investigated by measuring the absorbance of the residual dye solution after different contact times. The prepared pellets were also studied in terms of their recyclability. After the adsorption step, the pellets were heated up to 150 °C for 3 h, and the phase composition was studied by XRD. The adsorption tests were repeated for five consecutive cycles, with each cycle being run four times to ensure the reproducibility of the obtained results. Figure 1 shows the schematic diagram of the preparation process of porous glass microsphere pellets from waste glass and its applicability for methylene blue adsorption.

Characterization of the sorbent pellets

The obtained materials after the first and second alkali activation were finely ground and analyzed using X-ray diffractometer Bruker AXS at room temperature, using Cu Kα radiation (λ = 1.5405 Å), in the 2θ range from 10 to 70°, 0.02°/step, 2 s/step and 40 kV/40 mA to analyze the phase composition. The morphology and the microstructure of the porous glass microspheres were examined before and after applying alkali activation, using optical stereomicroscopy (Carl Zeiss Microscopy, Thornwood, New York, US) and a scanning electron microscopy (SEM, FEI Quanta 200 ESEM, Eindhoven, The Netherlands).

Absorption infrared spectra of glass particles were recorded using an FT/IR-4200 Fourier transform infrared spectrometers (JASCO, USA). The absorption spectra were recorded in the wavenumber range of 400–4000 cm−1, using a Standard Pike ATR cell. The specific surface area before and after second alkali activation was measured by N2 physisorption at − 196 °C (ASAP 2010, Micromeritics, Norcross, GA, USA). Porous glass microspheres were degassed at 150 °C, and the specific surface area was calculated in the relative pressure (p/p0) range between 0.05 and 0.30 by applying the Brunauer–Emmett–Teller (BET) multipoint method. The geometric density of the pellet was estimated by considering the mass-to-volume ratio. The apparent and the true density were measured by a helium pycnometer (Anton Paar, Ultrapyc 3000), operating on bulk or on finely crushed samples, respectively. The three densities were used to calculate the amounts of open and closed porosity.

Adsorption process

The adsorption activity of the prepared porous pellets was investigated using methylene blue dye as a reference contaminant. The experiments were carried out using a 250 mL beaker with a porous glass pellet (100 mg) and 100 mL of the methylene blue solution with initial concentrations of 50–500 mg/L. All measurements were carried out at room temperature. After the adsorption step, the pellet was separated. The concentration of the dye in the solution was determined using a UV–VIS spectrophotometer (Jasco V-650, USA) at the wavelength of 664 nm (λmax). The adsorption capacity (mg/g) of the dye was calculated using Eq. (1), where C0 represents the initial concentration of methylene blue (mg/L), Ce is the equilibrium concentration which equals the concentration of the dye remaining in the flask (mg/L) at the end of the experiment, V is the volume of the used solution (L) and W is the weight of the pellet (adsorbent) (g).

To study the kinetics of the adsorption process, 100 mg of the adsorbent pellet was immersed in 100 mL of the methylene blue dye solutions with the concentrations of 100, 200 and 300 mg/L. The concentration of the dye in the solution was measured at the end of each time interval by UV–VIS spectrophotometry as specified above, until an equilibrium was reached.

Adsorption isotherm models

The effectiveness of the microspheres as a sorbent material was determined by their capacity to adsorb the dye. This capacity was determined by fitting the experimental data with a suitable adsorption isotherm, from which the Langmuir, Freundlich and Temkin adsorption isotherms are the most frequently applied. These three types of adsorption isotherm models were used for fitting the experimental data obtained in this work:

where qe, Ce, Qm and KL represent the equilibrium adsorption (mg/g), the equilibrium dye concentration (mg/L), the maximum dye capacity (mg/g) and the Langmuir equilibrium constant (L/mg), respectively. qf and n are the Freundlich constant (mg/g) and the heterogeneity factor, respectively, bT, AT, R and T represent the Temkin constant (J/mol), the Temkin isotherm equilibrium constant (L/g), the gas constant (8.3145 J/mol/K) and the absolute temperature (298 K), respectively.

Kinetic models

Pseudo-first and pseudo-second-order models were applied to investigate the kinetic parameters of the adsorption of the methylene blue dye. The linearized form of the pseudo-first- and pseudo-second-order models are given below as Eqs. (5) and (6), respectively:

where qe and qt are the amounts of the dye adsorbed at the equilibrium (mg/g) and the amount of the dye adsorbed at the time t (mg/g), respectively. k1 and k2 represent the first-order rate (min−1) and the second-order rate constants (g/mg min).

Thermodynamic parameters

The thermodynamic aspects of methylene blue adsorption onto porous glass microspheres pellet were assessed through the determination of thermodynamic parameters, namely Gibbs free energy change (ΔG°), enthalpy change (ΔH°) and entropy change (ΔS°). These parameters were computed employing the subsequent equations, illustrating the thermodynamic behavior of the adsorption process:

where Kd is the distribution coefficient; Ca is the amount of methylene blue adsorbed on the porous glass microspheres pellet at equilibrium, mg/L; Ce is the equilibrium concentration of methylene blue in solution, mg/L; T is the solution temperature, K; R is the gas constant.

Result and discussion

Previous studies of alkali activation and gel casting [14,15,16] concluded that the hardening of glass suspensions does not rely on the formation of a specific binding phase. Generally, when applying the same alkaline activator, the nature of the formed gel is related to the chemical compositions of the treated glass. Calcium silicate hydrate (C–S–H) compounds are mainly formed for calcia-rich and alumina-poor glasses [17]. Sodium aluminum silicate hydrate (N–A–S–H) compounds are characteristic of calcia-poor and alumina-rich glasses [15].

XRD patterns before and after the first and second alkali activation are shown in Fig. 2. The precursors (fiber glass waste) were not fully X-ray amorphous, but contained a minor crystalline phase—unidentified by XRD due to the low intensity of the diffraction maxima. The alkali activation by 9M KOH resulted in the formation of tobermorite (Ca5(Si6O16) (OH)2 [PDF 89-6458], represented by the diffraction maxima at 2θ (29.77°, 32.4° and 43.2°), potassium carbonate hydrate [PDF 73-0470] with the maxima at 2θ (12.8°, 32.38° and 32.66°) and potassium aluminum silicate hydrate [PDF 38-0216] with the main diffraction lines at 2θ (13.54°, 18.68° and 30.19°). The formed hydrated compounds decomposed at elevated temperatures and released gases such as CO2 and water vapor, which were responsible for the formation of porous structures of prepared glass microspheres [18]. The XRD analysis of the prepared porous glass microspheres after the flame synthesis confirmed their amorphous nature, indicating the decomposition of all hydrated compounds [19, 20].

The second alkali activation resulted in the formation of sodalite (Na8[AlSiO4]6(OH)2·2H2O) with the diffraction maxima at 2θ (26.26°, 31.83° and 34.96°) [PDF 76-1639], sodium carbonate hydrate (Na2CO3·10H2O) [PDF 25-0816] with the maxima at 2θ (24.05°, 28.75° and 39.78°), along with tobermorite [PDF 89-6458] [21].

Ramteke et al. reported that alkali activation of fiber glass did not yield calcium silicate hydrate compounds at low concentrations of the alkali solution (1 M NaOH). Moreover, the obtained materials could be easily crushed due to the poor bonding between glass particles [18]. In the current study, using 2.5 M NaOH for alkali activation of glass microspheres led to partial dissolution of glass and therefore to the formation of strong bonds by forming mixed phases (sodalite, tobermorite and sodium carbonate hydrate).

SEM examination confirmed the differences in the microstructure of porous microspheres before and after the second alkali activation (Fig. 3). The higher molarity of the first alkali activation solution enhanced the formation of hydrated compounds, which were responsible for the gas release during the flame synthesis. Porous glass microspheres are produced only if some gases remain released at the temperatures at which droplets of molten glass are formed. The activation with 9M KOH led to significant gas evolution from 800 to 950 °C [4]. The prepared porous glass microspheres are shown in Fig. 3a and Fig. 3b. Inducing second alkali activation changed the microstructure to more porous via etching the surface (Fig. 3c and Fig. 3d) and forming the gel that connects the microspheres together. The formed gel is marked by red arrows in Fig. 3e. Moreover, Fig. 3f shows the formed crystalline phases (marked by red arrows) on the surface of porous glass microspheres.

The bulk density of the pellet was 0.85 g/cm3, while the apparent density and the true density were 2.42 and 2.76 g/cm3, respectively. The total porosity of the prepared pellet reached 70%. The specific surface area increased from 8.6 (before etching) to 19.7 (after etching) m2/g, which indicates increasing pore volume and higher number of adsorbing sites.

Adsorption isotherm studies

The calibration of methylene blue absorbance was conducted by varying the initial methylene blue concentration (0.5, 1, 1.5, 2, 2.5 mg/L). The results are shown in Fig. 4a. The absorption of the methylene blue by the pellet increased by increasing the initial concentration of methylene blue until an equilibrium (the plateau part) was achieved (Fig. 4b).

The interaction between the pellets prepared from porous glass microspheres and methylene blue dye was evaluated by equilibrium batch adsorption experiments. Equilibrium isotherms were determined using various initial concentrations of methylene blue (50–700 mg/L). The obtained data were then fitted by the Langmuir, Freundlich and Temkin adsorption isotherm models to predict the theoretical adsorption capacity (qe). The corresponding parameters along with the regression coefficients are summarized in Table 1. Figure 4b shows the concentration dependence of the adsorption capacity of the pellet. At the initial dye concentration (50 mg/L), the adsorption capacity was 22 mg/g, respectively, increasing to 70 and 108 mg/g for the concentrations of 100 and 200 mg/L. At higher concentrations of the dye (300–700 mg/L), the equilibrium of 122 mg/g was achieved, as documented in Table 1 and Fig. 4b. The results compares well with what reported by Tsai and Horng [22], who transformed glass fiber waste into mesoporous zeolite-like nanomaterials.

As shown in Table 1, the fitting of the experimental data was better with the Langmuir isotherm model with R2 = 0.99 as compared to the Freundlich and Temkin model with R2 = 0.97 and 0.98, respectively. The obtained results can be thus described by the Langmuir model that assumes the adsorbent surface shows a finite number of adsorption sites. Another assumption is that there are no further interactions between methylene blue and the formed monolayer when the adsorbent surface reaches saturation [23, 24]. The Langmuir monolayer maximum adsorption capacity was 144 mg/g. Freundlich and Temkin adsorption isotherm models did not fit the results satisfactorily. For instance, a favorable adsorption process from Freundlich isotherm only could be assumed when the value of 1/n is less than 1 [25] which, as shown in Table 1, did not match the results obtained in this study.

Figure 5a and b shows the pellet prepared from porous glass microspheres before and after methylene blue adsorption. The pure white color of porous glass microspheres in Fig. 5c changed to dark blue after the maximum equilibrium dye adsorption was achieved. The examination of the pellet by optical microscopy after immersing it in the dye showed that the dye was evenly distributed all over the surface (Fig. 5d).

Specific indications concerning the nature of the compounds formed upon second alkali activation, may come from the FTIR spectrum, as revealed in Fig. 6. The wide peak in the 3000–3600 cm−1 interval is related to C–S–H gels [14], while O–H bending vibrations are represented by the peak with the maximum around 1750 cm−1. At 1458 cm−1 a high intensity band attributed to the hydrate carbonate phase is visible for activated glass microspheres [15]. It is reported that the region between 900 and 980 cm−1 is assigned to stretching vibration of free silanol groups, while 1000–1260 cm−1 is related to asymmetric stretching vibrations of Si–O–Si bridging sequence [26]. After the methylene blue adsorption, the spectral bands at around 2720 and 2816 cm−1 can be assigned to the stretching vibrations of C–H and CH3, whereas the peak observed at 1490 cm−1 can be attributed to the stretching vibration of the aromatic ring. The other functional groups related to methylene blue absorption are reflected by the –NH/–OH overlapped stretching vibration at 3443 cm−1, and the vibration of C–N at 854 cm−1 [27].

Adsorption kinetics studies

The influence of different initial concentrations of methylene blue (100, 200 and 300 mg/L) on the adsorption capacity of porous glass microspheres pellet (qe) is plotted in Fig. 7. The dye adsorption increased initially, then dropped, followed by a plateau toward an equilibrium. The increase in the initial dye concentration led to an increase in the adsorption capacity. Pseudo-first- and second-order rate constants and the calculated adsorption capacities (qecal) were investigated from the models revealed in Table 1 along with the corresponding correlation coefficients. The adsorption capacity of the porous glass microspheres pellet followed pseudo-second-order kinetics, where the calculated adsorption capacities were close to the measured adsorption capacitates for the applied initial dye concentrations (100–300 mg/L).

In the first stage, the concentration of adsorbed methylene blue molecules gradually increased with increasing the adsorption time, reaching the maximum after 2 h (Fig. 7). From the second to fourth hour of adsorption, a slight desorption occurred until the adsorption reached an equilibrium after 5 h. The adsorption behavior of pellets prepared from porous glass microspheres was similar at all tested initial dye concentrations (100–300 mg/L). The highly efficient dye removal is attributed to increasing the adsorption capacity of the porous glass microspheres due to various aspects such as increased surface area, open porosity, interconnected channels and formed crystalline phases. The surface area of the porous glass microspheres after the second alkali activation was higher than that of the initial materials, which favors the adsorption of methylene blue molecules.

The thermodynamic parameters for the adsorption of methylene blue onto porous glass microsphere pellets at different temperatures (298 K, 308 K, 318 K) and concentrations (100 mg/L, 200 mg/L, 300 mg/L) are presented in Table 2. The Gibbs free energy change (ΔG°) increased from negative to positive with increasing concentration, indicating a non-spontaneous adsorption process. This suggests that elevated temperatures are required to achieve maximum adsorption.

The positive ΔH° value confirms that the methylene blue adsorption process is endothermic. At lower initial concentrations, the adsorption process likely involves the dispersion of adsorbate molecules on the adsorbent surface. This dispersion increases entropy, as the adsorbate molecules have greater freedom of movement when dispersed compared to being clustered together. This implies weaker interactions among adsorbate molecules and between the adsorbate and the surface, resulting in increased system disorder (entropy).

As the initial concentration of methylene blue increases, the available adsorption sites on the porous glass surface become progressively occupied. At higher concentrations, adsorbate molecules may interact more strongly, potentially forming clusters or layers on the surface. These interactions and the formation of ordered structures can lead to a reduction in entropy, indicating a more organized system with less randomness or disorder. This complexity underscores the influence of various factors, including concentration, temperature, surface properties and intermolecular interactions, on adsorption processes [28].

The diffusion of the dye through the interconnected pores of porous glass microspheres can occur within each microsphere due to their multiple entrance and exit points [29]. The partially charged activated glass microspheres interact electrostatically with the cationic methylene blue species, in addition to forming of the hydrogen bonds [30]. This interaction facilitates the adsorption process, as illustrated in Fig. 8. Furthermore, the formation of sodium aluminum silicate hydrate phase increases the adsorption capacity of the surface. Additionally, the carbonate phases can also act as adsorbent centers [30].

The decrease of intensities of Si–O–Si stretching vibration of the obtained glass microspheres could be attributed to the Lewis acid–base interaction between the Ca2+ and basic components (N, S) of the methylene blue dye. FTIR analysis confirmed the presence of a variety of functional groups on the surface of activated glass microspheres, that could act as binding sites for the potential attachment of dye molecules [31]. Converting glass waste into porous glass microspheres introduced some promising and unique characteristics, such as high surface area and active surface properties, are the main factors for being highly efficient adsorbents.

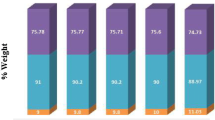

The regeneration of porous glass microsphere pellets was achieved by heating them at 150 °C for 3 h, which resulted in the complete decomposition of the methylene blue species. The recyclability study was carried out to investigate the stability of the adsorbent (pellet). The recovered pellets were applied for repeated methylene blue adsorption tests performed under the same condition as the first adsorption cycle. A 6% decrease in adsorption capacity was observed after the fifth cycle, as shown in Fig. 9, indicating that the regeneration process did not significantly affect the textural properties of the substrate and the slight change of the sorbent mass [32]. XRD of the recycled pellet showed that the zeolite phase did not decompose (Fig. 2), which was the main reason for bonding the particles to each other.

Table 3 shows a comparison between the adsorption capacities (qe) for methylene blue characterized in this study with other applied materials reported in the recent literature. The pellet of glass microspheres exceeded dye adsorption capacity of other adsorbents reported in the literature, with the exception of mesoporous zeolite-like material.

The reported adsorption capacity for methylene blue by a broad range of silica-based adsorbents, including as-prepared glass composite membranes, silica xerogel, pure silica, hollow silica and hydroxyl group silica aerogel, were in the range of 44–102 mg/g. In the present work, the adsorption capacity of methylene blue by the pellet of porous glass microspheres was higher (122 mg/g) than in the reported studies, demonstrating that the obtained pellet is a suitable material for the adsorption of the cationic methylene blue.

Conclusion

Unrecycled fiber glass waste has been upcycled by the preparation of highly adsorbing pellets formed from porous glass microspheres. The flame spheroidization process at 1600 °C was applied to convert the glass waste into porous glass microspheres. Applying double alkali activation resulted in an enhancement of the number of pores and an increase in the specific surface area from 8.6 to 19.7 m2/g. The total porosity of the prepared pellet reached 70%. The pellets prepared from porous glass microspheres were found to be an efficient material in remediating higher methylene blue concentrations from water. The equilibrium and kinetic of adsorbing methylene blue by the pellet were successfully described by Langmuir isotherm and a pseudo-second-order kinetic, respectively. The calculated Langmuir monolayer maximum adsorption capacity was 144 mg/g. The thermodynamic analysis of methylene blue adsorption onto porous glass microsphere pellets reveals that the process is non-spontaneous and benefits from higher temperatures to achieve optimal adsorption. The endothermic nature of the adsorption, especially at lower concentrations, suggests that increased entropy results from dispersed adsorbate molecules, while higher concentrations promote stronger adsorbate interactions, leading to a more organized system with reduced entropy.

References

Karasu B et al (2019) Glass microspheres. El-Cezeri Fen ve Mühendislik Dergisi 6:613–641

Hossain KMZ et al (2018) Porous calcium phosphate glass microspheres for orthobiologic applications. Acta Biomater 72:396–406

Vossberg C, Mason-Jones K, Cohen B (2014) An energetic life cycle assessment of C&D waste and container glass recycling in Cape Town, South Africa. Resour Conserv Recycl 88:39–49

Mahmoud M et al (2022) Porous glass microspheres from alkali-activated fiber glass waste. Materials 15(3):1043

Matamoros-Veloza A et al (2020) Formulating injectable pastes of porous calcium phosphate glass microspheres for bone regeneration applications. J Mech Behav Biomed Mater 102:103489

Tan KB et al (2015) Adsorption of dyes by nanomaterials: recent developments and adsorption mechanisms. Sep Purif Technol 150:229–242

Dias EM, Petit C (2015) Towards the use of metal–organic frameworks for water reuse: a review of the recent advances in the field of organic pollutants removal and degradation and the next steps in the field. J Mater Chem A 3(45):22484–22506

Kandisa RV, Saibaba KN (2016) Dye removal by adsorption: a review. J Bioremediat Biodegrad 7(6):1–4

Sajab MS et al (2011) Citric acid modified kenaf core fibres for removal of methylene blue from aqueous solution. Bioresour Technol 102(15):7237–7243

Wang L et al (2008) Structure–properties relationships investigation on the azo dyes derived from benzene sulfonamide intermediates. Dyes Pigm 76(3):636–645

Jyothi D et al (2011) Transition metal oxide loaded MCM catalysts for photocatalytic degradation of dyes. J Chem Sci 124(2):385–393

Khin MM et al (2012) A review on nanomaterials for environmental remediation. Energy Environ Sci 5(8):8075–8109

Pradhan AC, Paul A, Rao GR (2017) Sol-gel-cum-hydrothermal synthesis of mesoporous Co–Fe@Al2O3−MCM-41 for methylene blue remediation. J Chem Sci 129(3):381–395

Rincón A et al (2017) Novel ‘inorganic gel casting’ process for the manufacturing of glass foams. J Eur Ceram Soc 37(5):2227–2234

Rincon Romero A, Salvo M, Bernardo E (2018) Up-cycling of vitrified bottom ash from MSWI into glass-ceramic foams by means of ‘inorganic gel casting’ and sinter-crystallization. Construct Build Mater 192:133–140

Rincon Romero A et al (2019) Glass-ceramic foams from “weak alkali activation” and gel-casting of waste glass/fly ash mixtures. Materials (Basel) 12(4):588

Tilocca A (2015) Atomic-scale models of early-stage alkali depletion and SiO2-rich gel formation in bioactive glasses. Phys Chem Chem Phys 17(4):2696–2702

Ramteke DD et al (2021) Up-cycling of ‘unrecyclable’ glasses in glass-based foams by weak alkali-activation, gel casting and low-temperature sintering. J Clean Prod 278:123985

Kraxner J et al (2019) Porous bioactive glass microspheres prepared by flame synthesis process. Mater Lett 256:126625

Nuzulia NA et al (2022) Developing highly porous glass microspheres via a single-stage flame spheroidisation process. J Phys Conf Ser 2243(1):012005

Zhang Q, Ye G (2012) Dehydration kinetics of Portland cement paste at high temperature. J Therm Anal Calorim 110(1):153–158

Tsai C-K, Horng J-J (2021) Transformation of glass fiber waste into mesoporous zeolite-like nanomaterials with efficient adsorption of methylene blue. Sustainability 13(11):6207

Sayğılı H, Akkaya Sayğılı G, Güzel F (2018) Surface modification of black tea waste using bleaching technique for enhanced biosorption of methylene blue in aqueous environment. Sep Sci Technol 53(18):2882–2895

Li B et al (2019) Adsorption of methylene blue and Cd(II) onto maleylated modified hydrochar from water. Environ Pollut 254(Pt B):113014

Ayawei N, Ebelegi AN, Wankasi D (2017) Modelling and interpretation of adsorption isotherms. J Chem 2017:1–11

Hruška B et al (2020) Raman spectroscopy study of glass corrosion. Vib Spectrosc 109:103096

Dinh V-P et al (2019) Insight into the adsorption mechanisms of methylene blue and chromium(iii) from aqueous solution onto pomelo fruit peel. RSC Adv 9(44):25847–25860

Gouamid M, Ouahrani MR, Bensaci MB (2013) Adsorption equilibrium, kinetics and thermodynamics of methylene blue from aqueous solutions using date palm leaves. Energy Procedia 36:898–907

Ming L, Wang M-L, Cheng S-Y (2019) Permeability model for porous transducer with glass spheres packing. IEEE Access 7:56190–56197

Samad SA et al (2021) Adsorption studies and effect of heat treatment on porous glass microspheres. Int J Appl Glass Sci 13:63–81

Yusof NH et al (2020) One-step synthesis of chitosan-polyethyleneimine with calcium chloride as effective adsorbent for acid red 88 removal. Int J Biol Macromol 157:648–658

Mahmoud M et al (2022) Advanced dye sorbents from combined stereolithography 3D printing and alkali activation of pharmaceutical glass waste. Materials 15:6823

Zhang Y et al (2019) Preparation of reusable glass hollow fiber membranes and methylene blue adsorption. J Eur Ceram Soc 39(15):4891–4900

Guzel Kaya G, Yilmaz E, Deveci H (2019) A novel silica xerogel synthesized from volcanic tuff as an adsorbent for high-efficient removal of methylene blue: parameter optimization using Taguchi experimental design. J Chem Technol Biotechnol 94(8):2729–2737

Alizadeh Arasi M, Salem A, Salem S (2020) Extraction of nano-porous silica from hydrosodalite produced via modification of low-grade kaolin for removal of methylene blue from wastewater. J Chem Technol Biotechnol 95(7):1989–2000

Verma M, Dwivedi PK, Saxena NS (2020) Hollow silica nanoparticles synthesized from core-shell nanoparticles as highly efficient adsorbent for methylene blue and its invitro release: mechanism and kinetics study. Colloids Surf A Physiochem Eng Aspects 587:124333

Han H et al (2016) Removal of cationic dyes from aqueous solution by adsorption onto hydrophobic/hydrophilic silica aerogel. Colloids Surf A Physiochem Eng Aspects 509:539–549

Brião GV et al (2018) Highly efficient and reusable mesoporous zeolite synthetized from a biopolymer for cationic dyes adsorption. Colloids Surf A Physiochem Eng Aspects 556:43–50

Acknowledgements

This paper is a part of the dissemination activities of the project FunGlass. This project has received funding from the European Union´s Horizon 2020 research and innovation program under Grant agreement No 739566. Publication was created also in the framework of the project: Advancement and support of R&D for Centre for diagnostics and quality testing of materials in the domains of the RIS3 SK specialization, ITMS2014+:313011W442, based on the Operational Programme Integrated Infrastructure and funded from the European Regional Development Fund. The authors also gratefully acknowledge the financial support from the Slovak Grant Agency of the Ministry of Education, Science, Research and Sport, VEGA No 1/0456/20.

Funding

Open access funding provided by Università degli Studi di Padova.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Dale Huber.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mahmoud, M., Kraxner, J., Elsayed, H. et al. Enhanced methylene blue adsorption by double alkali activation of highly porous glass microspheres prepared from waste glass. J Mater Sci 59, 73–85 (2024). https://doi.org/10.1007/s10853-023-09207-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09207-7