Abstract

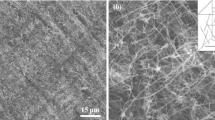

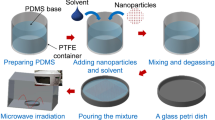

Three-dimensional flexible porous polydimethylsiloxane (pPDMS) materials are widely used in electronics due to their relatively large specific surface area, and so maintaining the electric charge at a high-humidity atmosphere is an issue that must be addressed. A method for combining centrifuging and hot embossing was proposed for rapid mass production of highly interconnected pPDMS sandwich sponges with microstructure on top layer. As optimized sacrificial templates, the salts were rearranged in the PDMS by this method, and so the high connectivity facilitated salts dissolving in 3 h, which greatly improved the efficiency of the whole fabrication period. The weight ratio of PDMS to salt was 1.0–3.5, and the porosity can be kept at ~ 70%. The combination of micron-scale truncated cones and highly interconnected pore structure endowed the sponge surface with a contact angle of up to ~ 153° and ice adhesion strength as low as ~ 6.78 kPa. The strategy to combine passive anti-icing with active deicing is to prepare PDMS/CNTs sandwich sponges with microstructure on top layer. For the PDMS/CNTs (7 wt%) sandwich sponge, the results show that the elongation at break is as high as ~ 161% and the stress is as low as ~ 23 kPa. Besides, its surface temperature rose rapidly from 25 to 100 °C in 10 s through far-infrared light (808 nm) irradiation, achieving a remote deicing effect. The superhydrophobic and anti-icing/deicing sponges with high toughness property are expected to be of use for further applications.

Graphical abstract

Similar content being viewed by others

References

Iglio R, Mariani S, Robbiano V, Strambini L, Barillaro G (2018) Flexible polydimethylsiloxane foams decorated with multiwalled carbon nanotubes enable unprecedented detection of ultralow strain and pressure coupled with a large working range. ACS Appl Mater Interfaces 10:13877–13885

Tan YJ, Li J, Cai JH, Tang XH, Liu JH, Hu ZQ, Wang M (2019) Comparative study on solid and hollow glass microspheres for enhanced electromagnetic interference shielding in polydimethylsiloxane/multi-walled carbon nanotube composites. Compos Part B Eng 177:107378

Cai JH, TangXH CXD, Wang M (2021) Temperature and strain-induced tunable electromagnetic interference shielding in polydimethylsiloxane/multi-walled carbon nanotube composites with temperature-sensitive microspheres. Compos Part A Appl Sci Manuf 140:106188

Ray TR, Choi J, Bandodkar AJ, Krishnan S, Gutruf P, Tian LM, Ghaffari R, Rogers JA (2019) Bio-integrated wearable systems: a comprehensive review. Chem Rev 119:5461–5533

Mata A, Fleischman AJ, Roy S (2005) Characterization of polydimethylsiloxane (PDMS) properties for biomedical micro/nanosystems. Biomed Microdevices 7:281–293

Huang C, Bian ZG, Fang CF, Zhou XL, Song JZ (2018) Experimental and theoretical study on mechanical properties of porous PDMS. J Appl Mech 85:041009

Chen XM, Weibel JA, Garimella SV (2016) Continuous oil−water separation using polydimethylsiloxane-functionalized melamine sponge. Ind Eng Chem Res 55:3596–3602

Rattanaumpa T, Naowanon W, Amnuaypanich S, Amnuaypanich S (2019) Polydimethylsiloxane sponges incorporated with mesoporous silica nanoparticles (PDMS/H-MSNs) and their selective solvent absorptions. Ind Eng Chem Res 58:21142–21154

Shi JR, Zhang HB, Jackson J, Shademani A, Chiao M (2016) A robust and refillable magnetic sponge capsule for remotely triggered drug release. J Mater Chem B 4:7415–7422

Zargar R, Nourmohammadi J, Amoabediny G (2016) Preparation, characterization, and silanization of 3D microporous PDMS structure with properly sized pores for endothelial cell culture. Biotechnol Appl Biochem 63:190–199

Li XR, Li YY, Huang YX, Zhang T, Liu YZ, Yang B, He CX, Zhou XC, Zhang JM (2017) Organic sponge photocatalysis. Green Chem 19:2925–2930

Liu LB, Yu Y, Yan C, Li K, Zheng ZJ (2015) Wearable energy-dense and power-dense supercapacitor yarns enabled by scalable graphene-metallic textile composite electrodes. Nat Commun 6:1–9

Chortos A, Liu J, Bao ZA (2016) Pursuing prosthetic electronic skin. Nat Mater 15:937–950

Lee S, Reuveny A, Reeder J, Lee S, Jin H, Liu QH, Yokota T, Sekitani T, Isoyama T, Abe Y, Suo ZG, Someya T (2016) A transparent bending-insensitive pressure sensor. Nat Nanotechnol 11:472–478

Fan YJ, Meng XS, Li HY, Kuang SY, Zhang L, Wu Y, Wang ZL, Zhu G (2017) Stretchable porous carbon nanotube-elastomer hybrid nanocomposite for harvesting mechanical energy. Adv Mater 29:1603115

Kim D, Park SJ, Jeon SB, Seol ML, Choi YK (2016) A triboelectric sponge fabricated from a cube sugar template by 3D soft lithography for superhydrophobicity and elasticity. Adv Electron Mater 2:1500331

Wang YM, Gao CJ, Hao WZ, Zheng GQ, Ji YX, Dai K, Mi LW, Zhang DB, Liu CT, Shen CY (2020) Large-area fabrication and applications of patterned surface with anisotropic superhydrophobicity. Appl Surf Sci 529:147027

Mandsberg NK, Taboryski R (2017) Spatial control of condensation on chemically homogeneous pillar-built surfaces. Langmuir 33:5197–5203

Hinton TJ, Hudson A, Pusch K, Lee A, Feinberg AW (2016) 3D printing PDMS elastomer in a hydrophilic support bath via freeform reversible embedding. ACS Biomater Sci Eng 2:1781–1786

Qin Z, Compton BG, Lewis JA, Buehler MJ (2015) Structural optimization of 3D-printed synthetic spider webs for high strength. Nat Commun 6:1–7

Cai JH, Huang ML, Chen XD, Wang M (2021) Thermo-expandable microspheres strengthened polydimethylsiloxane foam with unique softening behavior and high-efficient energy absorption. Appl Surf Sci 540:148364

Jung S, Kim JH, Kim J, Choi S, Lee J, Park I, Hyeon T, Kim DH (2014) Reverse-micelle-induced porous pressure-sensitive rubber for wearable human-machine interfaces. Adv Mater 26:4825–4830

Zhao X, Li LX, Li BC, Zhang JP, Wang AQ (2014) Durable superhydrophobic/superoleophilic PDMS sponges and their applications in selective oil absorption and in plugging oil leakages. J Mater Chem A 2:18281–18287

Liang SQ, Li YY, Yang JB, Zhang JM, He CX, Liu YZ, Zhou XC (2016) 3D stretchable, compressible, and highly conductive metal-coated polydimethylsiloxane sponges. Adv Mater Technol 1:1600117

Yu CL, Yu CM, Cui LY, Song ZY, Zhao XY, Ma Y, Jiang L (2017) Facile preparation of the porous PDMS oil-absorbent for oil/water separation. Adv Mater Interfaces 4:1600862

He ZW, Zhuo YZ, He JY, Zhang ZL (2018) Design and preparation of sandwich-like polydimethylsiloxane (PDMS) sponges with super-low ice adhesion. Soft Matter 14:4846–4851

Nguyen V, Yang RS (2013) Effect of humidity and pressure on the triboelectric nanogenerator. Nano Energy 2:604–608

Hejazi V, Sobolev K, Nosonovsky M (2013) From superhydrophobicity to icephobicity: forces and interaction analysis. Sci Rep 3:1–6

He ZW, Vagenes ET, Delabahan C, He JY, Zhang ZL (2017) Room temperature characteristics of polymer-based low ice adhesion surfaces. Sci Rep 7:1–7

Cai JH, Li J, Chen XD, Wang M (2020) Multifunctional polydimethylsiloxane foam with multi-walled carbon nanotube and thermo-expandable microsphere for temperature sensing, microwave shielding and piezoresistive sensor. Chem Eng J 393:124805

Zhang CQ, Liang HY, Liang DS, Lin ZR, Chen Q, Feng PJ, Wang QW (2021) Renewable castor-oil-based waterborne polyurethane networks:simultaneously showing high strength, self-healing, processability and tunable multishape memory. Angew Chem Int Edit 60:4289–4299

Wang X, Liang HY, Jiang JZ, Wang QW, Luo Y, Feng PJ, Zhang CQ (2020) A cysteine derivative-enabled ultrafast thiol–ene reaction for scalable synthesis of a fully bio-based internal emulsifier for high-toughness waterborne polyurethanes. Green Chem 22:5722–5729

Wu SY, Zhang J, Ladani RB, Ravindran AR, Mouritz AP, Kinloch AJ, Wang CH (2017) Novel electrically conductive porous PDMS/carbon nanofiber composites for deformable strain sensors and conductors. ACS Appl Mater Interfaces 9:14207–14215

He XM, Mu XJ, Wen Q, Wen ZY, Yang J, Hu CG, Shi HF (2016) Flexible and transparent triboelectric nanogenerator based on high performance well-ordered porous PDMS dielectric film. Nano Res 9:3714–3724

Chen HT, Miao LM, Su ZM, Song Y, Han MD, Chen XX, Cheng XL, Chen DM, Zhang HX (2017) Fingertip-inspired electronic skin based on triboelectric sliding sensing and porous piezoresistive pressure detection. Nano Energy 40:65–72

Li Q, Duan TT, Shao J, Yu HB (2018) Fabrication method for structured porous polydimethylsiloxane (PDMS). J Mater Sci 53:11873–11882. https://doi.org/10.1007/s10853-018-2396-z

Zhang S, Guo JH, Ma XY, Peng X, Qiu ZT, Ying J, Wang JK (2017) Smart PDMS sponge with switchable pH-responsive wetting surface for oil/water separation. New J Chem 41:8940–8946

Zhang AJ, Chen MJ, Du C, Guo HZ, Bai H, Li L (2013) Poly(dimethylsiloxane) oil absorbent with a three-dimensionally interconnected porous structure and swellable skeleton. ACS Appl Mater Interfaces 5:10201–10206

Ruan SL, Gaob P, Yang XG, Yu TX (2003) Toughening high performance ultrahigh molecular weight polyethylene using multiwalled carbon nanotubes. Polymer 44:5643–5654

Jung S, Tiwari MK, Doan NV, Poulikakos D (2012) Mechanism of supercooled droplet freezing on surfaces. Nat Commun 3:1–8

Yin XY, Zhang Y, Wang DA, Liu ZL, Liu YP, Pei XW, Yu B, Zhou F (2015) Integration of self-lubrication and near-infrared photothermogenesis for excellent anti-icing/deicing performance. Adv Funct Mater 25:4237–4245

Nosonovsky M, Hejazi V (2012) Why superhydrophobic surfaces are not always icephobic. ACS Nano 6:8488–8491

Yao HM, Gao HJ (2010) Gibson-soil-like materials achieve flaw-tolerant adhesion. J Comput Theor Nanosci 7:1299–1305

He ZW, Zhuo YZ, Wang F, He JY, Zhang ZL (2019) Understanding the role of hollow sub-surface structures in reducing ice adhesion strength. Soft Matter 15:2905–2910

He ZW, Xiao SB, Gao HJ, He JY, Zhang ZL (2017) Multiscale crack initiator promoted super-low ice adhesion surfaces. Soft Matter 13:6562–6568

Jiang G, Chen L, Zhang SD, Huang HX (2018) Superhydrophobic SiC/CNTs coatings with photothermal deicing and passive anti-icing properties. ACS Appl Mater Interfaces 10:36505–36511

Acknowledgements

Financial support provided by Supported by National Natural Science Foundation of China (Grant Nos. 52003057 and 51533003), the Opening Project of Key Laboratory of Polymer Processing Engineering (South China University of Technology), Ministry of Education (contract Grant Number: KFKT1901), and Foundation for Distinguished Young Talents in Higher Education of Guangdong, China (contract Grant Number: 2016KQNCX043) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict of financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Q., Chen, A., Gu, H. et al. Highly interconnected porous PDMS/CNTs sandwich sponges with anti-icing/deicing microstructured surfaces. J Mater Sci 56, 11723–11735 (2021). https://doi.org/10.1007/s10853-021-06052-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06052-4