Abstract

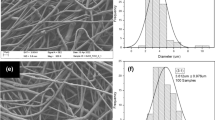

Tungsten disulfide polycrystalline microfibers were successfully synthesized by a process involving electrospinning, calcination, and sulfidation steps. We used an aqueous solution of silicotungstic acid (H4SiW12O40) and polyvinyl alcohol as precursors for the synthesis of composite fibers by the needle-less electrospinning technique. The obtained green composite fibers (av. diam. 460 nm) were converted by calcination in air to tungsten oxide WO3 fibers with traces of SiO2 and a smaller diameter (av. diam. 335 nm). The heat treatment of the WO3 fibers under flowing H2/H2S/N2 stream led to conversion to tungsten disulfide WS2 with retention of the fibrous morphology (av. diam. 196 nm). Characterization of the intermediate and final fibers was performed by the XRD, SEM, TEM, HAADF STEM EDS, elemental analyses ICP-OES, and IR spectroscopy methods.

Graphical abstract

Similar content being viewed by others

References

Ramakrishna S, Fujihara K, Teo W-E, Lim T-C, Ma Z (2005) An introduction to electrospinning and nanofibers. World Sci. https://doi.org/10.1142/5894

Li D, Xia Y (2004) Electrospinning of nanofibers: reinventing the wheel? Adv Mater 16:1151–1170. https://doi.org/10.1002/adma.200400719

Greiner A, Wendorff JH (2007) Electrospinning: a fascinating method for the preparation of ultrathin fibers. Angew Chem Int Ed 46:5670–5703. https://doi.org/10.1002/anie.200604646

Dai Y, Liu W, Formo E, Sun Y, Xia Y (2011) Ceramic nanofibers fabricated by electrospinning and their applications in catalysis, environmental science, and energy technology. Polym Adv Technol 22:326–338. https://doi.org/10.1002/pat.1839

Wu H, Pan W, Lin D, Li H (2012) Electrospinning of ceramic nanofibers: fabrication, assembly and applications. J Adv Ceram 1:2–23. https://doi.org/10.1007/s40145-012-0002-4

Esfahani H, Jose R, Ramakrishna S (2017) Electrospun ceramic nanofiber mats today: synthesis, properties, and applications. Materials 10:1238. https://doi.org/10.3390/ma10111238

Zhou X, Shang C, Gu L, Dong S, Chen X, Han P, Li L, Yao J, Liu Z, Xu H, Zhu Y, Cui G (2011) Mesoporous coaxial titanium nitride-vanadium nitride fibers of core–shell structures for high-performance supercapacitors. ACS Appl Mater Interfaces 3:3058–3063. https://doi.org/10.1021/am200564b

Zhou X, Qiu Y, Yu J, Yin J, Gao S (2011) Tungsten carbide nanofibers prepared by electrospinning with high electrocatalytic activity for oxygen reduction. Int J Hydrogen Energy 36:7398–7404. https://doi.org/10.1016/j.ijhydene.2011.03.081

Yang Y, Wang H, Lu X, Zhao Y, Li X, Wang C (2007) Electrospinning of carbon/CdS coaxial nanofibers with photoluminescence and conductive properties. Mater Sci Eng B 140:48–52. https://doi.org/10.1016/j.mseb.2007.03.010

Jirsak O, Sanetrnik O, Lukas D, Kotek V, Martinova L, Chaloupek J (2005) A Method of nanofibres production from a polymer solution using electrostatic spinning and a device for carrying out the method. WO 2005/024101 A1, 2005

Jirsak O, Petrik S (2012) Recent advances in nanofibre technology: needleless electrospinning. Int J Nanotechnol 9:836–845. https://doi.org/10.1504/IJNT.2012.046756

Zukalova M, Prochazka J, Bastl Z, Duchoslav J, Rubacek L, Havlicek D, Kavan L (2010) Facile conversion of electrospun Tio2 into titanium nitride/oxynitride fibers. Chem Mater 22:4045–4055. https://doi.org/10.1021/cm100877h

Misono M (2009) Recent progress in the practical applications of heteropolyacid and perovskite catalysts: catalytic technology for the sustainable society. Catal Today 144:285–291. https://doi.org/10.1016/j.cattod.2008.10.054

Kourasi M, Wills RGA, Shah AA, Walsh FC (2014) Heteropolyacids for fuel cell applications. Electrochim Acta 127:454–466. https://doi.org/10.1016/j.electacta.2014.02.006

Mohl M, Rautio A-R, Asres GA, Wasala M, Patil PD, Talapatra S, Kordas K (2020) 2D Tungsten chalcogenides: synthesis, properties and applications. advanced materials. Interfaces 7:2000002. https://doi.org/10.1002/admi.202000002

Eftekhari A (2017) Tungsten dichalcogenides (WS2, WSe2, and WTe2): materials chemistry and applications. J Mater Chem A 5:18299–18325. https://doi.org/10.1039/c7ta04268j

Voiry D, Yamaguchi H, Li J, Silva R, Alves DCB, Fujita T, Chen M, Asefa T, Shenoy VB, Eda E, Chhowalla M (2013) Enhanced catalytic activity in strained chemically exfoliated WS2 nanosheets for hydrogen evolution. Nat Mater 12:850–855. https://doi.org/10.1038/NMAT3700

Wang K, Feng W-L, Qin X, Deng D-S, Feng X, Zhang C (2017) Tungsten sulfide nanoflakes: synthesis by electrospinning and their gas sensing properties. Z Naturforschung 72(4):375–381. https://doi.org/10.1515/zna-2016-0379

Youn D-H, Kim B-J, Yun SJ (2020) Synthesis and gas sensing properties of WS2 nanocrystallites assembled hierarchical WS2 fibers by electrospinning. Nanotechnology 31:105602. https://doi.org/10.1088/1361-6528/ab58a9

Rapoport L, Fleischer N, Tenne R (2005) Applications of WS2 (MoS2) inorganic nanotubes and fullerene-like nanoparticles for solid lubrication and for structural nanocomposites. J Mater Chem 15:1782–1788. https://doi.org/10.1039/b417488g

Xu X, Li X, Zhang J, Qiao K, Han D, Wei S, Xing W, Yan Z (2019) Surfactant assisted electrospinning of WS2 nanofibers and its promising performance as anode material of sodium-ion batteries. Electrochim Acta 302:259–269. https://doi.org/10.1016/j.electacta.2019.02.042

Tenne R, Redlich M (2010) Recent progress in the research of inorganic fullerene-like nanoparticles and inorganic nanotubes. Chem Soc Rev 39:1423–1434. https://doi.org/10.1039/b901466g

Višić B, Panchakarla LS, Tenne R (2017) Inorganic nanotubes and fullerene-like nanoparticles at the crossroads between solid-state chemistry and nanotechnology. J Am Chem Soc 139:12865–12878. https://doi.org/10.1021/jacs.7b01652

Albu-Yaron A, Sinha SS, Tenne R (2020) Nanotubes from two-dimensional materials in contemporary energy research: historical and perspective outlook. ACS Energy Lett 5:1498–1511. https://doi.org/10.1021/acsenergylett.0c00185

Yin W, Liu X, Zhang X, Gao X, Colvin VL, Zhang Y, Yu WW (2020) Synthesis of tungsten disulfide and molybdenum disulfide quantum dots and their applications. Chem Mater 32:4409–4424. https://doi.org/10.1021/acs.chemmater.0c01441

Zhu Y, Zhang X, Ji Y, Feng Y, Zhang J (2013) Fabrication of WS2 nanofibers from WO3 nanofibers prepared by an electrospinning method. J Nanosci Nanotechnol 13:1983–1987. https://doi.org/10.1166/jnn.2013.7139

Feldman Y, Frey GL, Homyonfer M, Lyakhovitskaya V, Margulis L, Cohen H, Hodes G, Hutchison JL, Tenne R (1996) Bulk synthesis of inorganic fullerene-like MS2 (M=Mo, W) from the respective trioxides and the reaction mechanism. J Am Chem Soc 118:5362–5367. https://doi.org/10.1021/ja9602408

Petras D, Mares L, Stranska D (2008) Method and device for production of nanofibers from polymeric solution through electrostatic spinning. US Patent US 2008/0307766A1

Koski A, Yim K, Shivkumar S (2004) Effect of molecular weight on fibrous PVA produced by electrospinning. Mater Lett 58:493–497. https://doi.org/10.1016/S0167-577X(03)00532-9

Tao J, Shivkumar S (2007) Molecular weight dependent structural regimes during the electrospinning of PVA. Mater Lett 61:2325–2328. https://doi.org/10.1016/j.matlet.2006.09.004

Alcohol MP, Clariant (1999)

Pallas NR, Harrison Y (1990) An automated drop shape apparatus and the surface tension of pure water. Colloids Surf 43:169–194. https://doi.org/10.1016/0166-6622(90)80287-E

Zhang C, Yuan X, Wu L, Han Y, Sheng J (2005) Study on morphology of electrospun poly(vinyl alcohol) mats. Eur Polymer J 41:423–432. https://doi.org/10.1016/j.eurpolymj.2004.10.027

Ketpang K, Kim M, Kim S, Shanmugam S (2013) High performance catalyst for electrochemical hydrogen evolution reaction based on SiO2/WO3−x nanofacets. Int J Hydrog Energy 38:9732–9740. https://doi.org/10.1016/j.ijhydene.2013.05.112

Vasu K, Meiron OE, Enyashin AN, Bar-Ziv R, Bar-Sadan M (2019) Effect of ru doping on the properties of MoSe2 nanoflowers. J Phys Chem C 123:1987–1994. https://doi.org/10.1021/acs.jpcc.8b11712

Acknowledgements

We thank Dr. Y. Feldman for the XRD analysis. This research has been financially supported by the MEYS CR under the project CEITEC 2020 (LQ1601) and the Horizon 2020 Research and Innovation Programme under the Grant Agreement No. 810626 (SINNCE). CIISB research infrastructure project LM2018127 funded by the MEYS CR is gratefully acknowledged for the financial support of the measurements at the CEITEC MU CF X-ray Diffraction and Bio-SAXS and the CF Cryo-electron Microscopy and Tomography. The support of the Irving and Cherna Moskowitz Center for Nano and Bio-Nano Imaging, the Perlman Family Foundation, the Kimmel Center for Nanoscale Science Grant No. 43535000350000, is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicting financial interest.

Additional information

Handling Editor: N. Ravishankar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kundrat, V., Rosentsveig, R., Brontvein, O. et al. Synthesis and characterization of WS2/SiO2 microfibers. J Mater Sci 56, 10834–10846 (2021). https://doi.org/10.1007/s10853-021-05979-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05979-y