Abstract

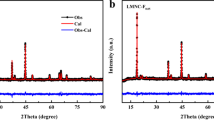

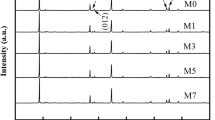

Li-rich layered oxides are identified as the most promising cathode material for lithium ion batteries due to their high specific capacity and energy density. However, capacity fading, voltage decay and inferior rate capability have restricted its development in industry. Herein, we developed a novel cation/anion (chromium/fluorine) co-doping methods to enhance the electrochemical performance of Li1.2Ni0.13Co0.13Mn0.54O2. X-ray diffraction, scanning electron microscopy, and transmission electron microscopy images reveal the perfect crystal structure. The Cr and F co-doped Li1.2Ni0.13Co0.13Mn0.54O2 shows the best discharge specific capacity, the highest rate performance and the lowest voltage decay. The initial discharge capacity is improved from 264.4 to 273.7 mAhg−1. The capacity retention ratio is enhanced from 78.84% to 94.46% after 50 cycles. The Rct (charge transfer resistance) is decreased from 556.1Ω to 199.5Ω. The lower Rct and higher DLi+ of the Cr and F co-doped Li1.2Ni0.13Co0.13Mn0.54O2 contribute to the excellent rate capability. More importantly, the co-doped material exhibits elevated discharge voltage and shows lower discharge mean voltage decay (0.2945 V) than that of the pristine material (0.4396 V). These results fully suggest that cation and anion doping could effectively improve the electrochemical performances of Li1.2Ni0.13Co0.13Mn0.54O2.

Graphical Abstract

Similar content being viewed by others

References

Zhao T, Ji R, Meng Y, Zhang G, Si H, Wang Y, Yang M, Wu F, Li L, Chen R (2019) In situ generated spinel-phase skin on layered Li-rich short nanorods as cathode materials for lithium-ion batteries. J Mater Sci 54(12):9098–9110. https://doi.org/10.1007/s10853-019-03425-8

Michalak B, Berkes BB, Sommer H, Bergfeldt T, Brezesinski T, Janek J (2016) Gas evolution in LiNi0.5Mn1.5O4/graphite cells studied in operando by a combination of differential electrochemical mass spectrometry, neutron imaging, and pressure measurements. Anal Chem 88(5):2877–2883. https://doi.org/10.1021/acs.analchem.5b04696

Qian J, Liu L, Yang J, Li S, Wang X, Zhuang HL, Lu Y (2018) Electrochemical surface passivation of LiCoO2 particles at ultrahigh voltage and its applications in lithium-based batteries. Nat Commun 9:4918. https://doi.org/10.1038/s41467-018-07296-6

Zhou A, Liu Q, Wang Y, Wang W, Yao X, Hu W, Zhang L, Yu X, Li J, Li H (2017) Al2O3 surface coating on LiCoO2 through a facile and scalable wet-chemical method towards high-energy cathode materials withstanding high cutoff voltages. J Mater Chem A 5(46):24361–24370. https://doi.org/10.1039/c7ta07312g

Tan XH, Liu HQ, Jiang Y, Liu GY, Guo YJ, Wang HF, Sun LF, Chu WG (2016) Graphite assisted synthesis of nanoparticles interconnected porous two-dimensional LiMn2O4 nanoplates with superior performance. J Power Sources 328:345–354. https://doi.org/10.1016/j.jpowsour.2016.08.038

Hua W-B, Wang S-N, Guo X-D, Chou S-L, Yin K, Zhong B-H, Dou S-X (2015) Vacuum induced self-assembling nanoporous LiMn2O4 for lithium ion batteries with superior high rate capability. Electrochim Acta 186:253–261. https://doi.org/10.1016/j.electacta.2015.10.093

Wang B, Xie Y, Liu T, Luo H, Wang B, Wang C, Wang L, Wang D, Dou S, Zhou Y (2017) LiFePO4 quantum-dots composite synthesized by a general microreactor strategy for ultra-high-rate lithium ion batteries. Nano Energy 42:363–372. https://doi.org/10.1016/j.nanoen.2017.11.040

Chen Y, Xiang K, Zhou W, Zhu Y, Bai N, Chen H (2018) LiFePO4/C ultra-thin nano-flakes with ultra-high rate capability and ultra-long cycling life for lithium ion batteries. J Alloys Compd 749:1063–1070. https://doi.org/10.1016/j.jallcom.2018.03.265

Liu K, Zhang Q, Dai S, Li W, Liu X, Ding F, Zhang J (2018) Synergistic effect of F- doping and LiF coating on improving the high-voltage cycling stability and rate capacity of LiNi0.5Co0.2Mn0.3O2 cathode materials for lithium-ion batteries. ACS Appl Mater Interfaces 10(40):34153–34162. https://doi.org/10.1021/acsami.8b10016

Xu S, Du C, Xu X, Han G, Zuo P, Cheng X, Ma Y, Yin G (2017) A mild surface washing method using protonated polyaniline for Ni-rich LiNi0.8Co0.1Mn0.1O2 material of lithium ion batteries. Electrochim Acta 248:534–540. https://doi.org/10.1016/j.electacta.2017.07.169

Yang H, Du K, Hu G, Peng Z, Cao Y, Wu K, Lu Y, Qi X, Mu K, Wu J (2018) Graphene@TiO2 co-modified LiNi0.6Co0.2Mn0.2O2 cathode materials with enhanced electrochemical performance under harsh conditions. Electrochim Acta 289:149–157. https://doi.org/10.1016/j.electacta.2018.08.089

Sun Y-K, Lee M-J, Yoon CS, Hassoun J, Amine K, Scrosati B (2012) The ROLE of AlF3 coatings in improving electrochemical cycling of li-enriched nickel-manganese oxide electrodes for Li-ion batteries. Adv Mater 24(9):1192–1196. https://doi.org/10.1002/adma.201104106

Yu H, Zhou H (2013) High-energy cathode materials (Li2MnO3-LiMO2) for lithium-ion batteries. J Phys Chem Lett 4(8):1268–1280. https://doi.org/10.1021/jz400032v

Guo H, Xia Y, Zhao H, Yin C, Jia K, Zhao F, Liu Z (2017) Stabilization effects of al doping for enhanced cycling performances of Li-rich layered oxides. Ceram Int 43(16):13845–13852. https://doi.org/10.1016/j.ceramint.2017.07.107

Ma J, Yan H, Li B, Xia Z, Huang W, An L, Xia D (2016) Tuning the electronic structure of the metal-oxygen group by silicon substitution in lithium-rich manganese-based oxides for superior performance. J Phys Chem C 120(25):13421–13426. https://doi.org/10.1021/acs.jpcc.6b04338

Meng H, Li L, Liu J, Han X, Zhang W, Liu X, Xu Q (2017) Surface modification of Li-rich layered Li Li0.17Ni0.17Co0.10Mn0.56 O-2 oxide with LiV3O8 as a cathode material for Li-ion batteries. J Alloys Compd 690:256–266. https://doi.org/10.1016/j.jallcom.2016.08.089

Wu B, Yang X, Jiang X, Zhang Y, Shu H, Gao P, Liu L, Wang X (2018) Synchronous tailoring surface structure and chemical composition of Li-rich-layered oxide for high-energy lithium-ion batteries. Adv Funct Mater 28(37):1803392. https://doi.org/10.1002/adfm.201803392

He H, Zan L, Zhang Y (2016) Effects of amorphous V2O5 coating on the electrochemical properties of Li Li0.2Mn0.54Ni0.13Co0.13 O-2 as cathode material for Li-ion batteries. J Alloys Compd 680:95–104. https://doi.org/10.1016/j.jallcom.2016.04.115

Wu F, Wang Z, Su Y, Yan N, Bao L, Chen S (2014) Li Li0.2Mn0.54Ni0.13Co0.13 O-2-MoO3 composite cathodes with low irreversible capacity loss for lithium ion batteries. J Power Sources 247:20–25. https://doi.org/10.1016/j.jpowsour.2013.08.031

Liu X, Liu J, Huang T, Yu A (2013) CaF2-coated Li1.2Mn0.54Ni0.13Co0.13O2 as cathode materials for Li-ion batteries. Electrochim Acta 109:52–58. https://doi.org/10.1016/j.electacta.2013.07.069

Lu C, Yang S, Wu H, Zhang Y, Yang X, Liang T (2016) Enhanced electrochemical performance of Li-rich Li1.2Mn0.52Co0.08Ni0.2O2 cathode materials for Li-ion batteries by vanadium doping. Electrochim Acta 209:448–455. https://doi.org/10.1016/j.electacta.2016.05.119

Xu M, Fei L, Lu W, Chen Z, Li T, Liu Y, Gao G, Lai Y, Zhang Z, Wang P, Huang H (2017) Engineering hetero-epitaxial nanostructures with aligned Li-ion channels in Li-rich layered oxides for high-performance cathode application. Nano Energy 35:271–280. https://doi.org/10.1016/j.nanoen.2017.03.051

Kim S, Cho W, Zhang X, Oshima Y, Choi JW (2016) A stable lithium-rich surface structure for lithium-rich layered cathode materials. Nat Commun 7:13598. https://doi.org/10.1038/ncomms13598

Yi T-F, Li Y-M, Cai X-D, Yang S-Y, Zhu Y-R (2017) Fe-stabilized Li-rich layered Li1.2Mn0.56Ni0.16Co0.08O2 oxide as a high performance cathode for advanced lithium-ion batteries. Mate Today Energy 4:25–33. https://doi.org/10.1016/j.mtener.2017.03.005

Ban L, Yin Y, Zhuang W, Lu H, Wang Z, Lu S (2015) Electrochemical performance improvement of Li-1.2 Mn0.54Ni0.13Co0.13 O-2 cathode material by sulfur incorporation. Electrochim Acta 180:218–226. https://doi.org/10.1016/j.electacta.2015.08.031

Jin X, Xu Q, Liu H, Yuan X, Xia Y (2014) Excellent rate capability of Mg doped Li Li0.2Ni0.13Co0.13Mn0.54 O-2 cathode material for lithium-ion battery. Electrochim Acta 136:19–26. https://doi.org/10.1016/j.electacta.2014.05.043

Ma Q, Li R, Zheng R, Liu Y, Huo H, Dai C (2016) Improving rate capability and decelerating voltage decay of Li-rich layered oxide cathodes via selenium doping to stabilize oxygen. J Power Sources 331:112–121. https://doi.org/10.1016/j.jpowsour.2016.08.137

Hu X, Guo H, Peng W, Wang Z, Li X, Hu Q (2018) Effects of Nb doping on the performance of 0.5Li(2)MnO(3).0.5LiNi(1/3)Co(1/3)Mn(1/3)O(2) cathode material for lithium-ion batteries. J Electroanal Chem 822:57–65. https://doi.org/10.1016/j.jelechem.2018.05.015

He Z, Wang Z, Chen H, Huang Z, Li X, Guo H, Wang R (2015) Electrochemical performance of zirconium doped lithium rich layered Li1.2Mn0.54Ni0.13Co0.13O2 oxide with porous hollow structure. J Power Sources 299:334–341. https://doi.org/10.1016/j.jpowsour.2015.09.025

Zheng J, Wu X, Yang Y (2013) Improved electrochemical performance of Li Li0.2Mn0.54Ni0.13Co0.13 O-2 cathode material by fluorine incorporation. Electrochim Acta 105:200–208. https://doi.org/10.1016/j.electacta.2013.04.150

Li H, Guo H, Wang Z, Wang J, Li X, Chen N, Gui W (2018) Improving rate capability and decelerating voltage decay of Li-rich layered oxide cathodes by chromium doping. Int J Hydrogen Energy 43(24):11109–11119. https://doi.org/10.1016/j.ijhydene.2018.04.203

Bian X, Fu Q, Pang Q, Gao Y, Wei Y, Zou B, Du F, Chen G (2016) Multi-functional surface engineering for li-excess layered cathode material targeting excellent electrochemical and thermal safety properties. ACS Appl Mater Interfaces 8(5):3308–3318. https://doi.org/10.1021/acsami.5b11199

Aklalouch M, Manuel Amarilla J, Rojas RM, Saadoune I, Maria Rojo J (2008) Chromium doping as a new approach to improve the cycling performance at high temperature of 5V LiNi0.5Mn1.5O4-based positive electrode. J Power Sources 185(1):501–511. https://doi.org/10.1016/j.jpowsour.2008.06.074

Li L, Song BH, Chang YL, Xia H, Yang JR, Lee KS, Lu L (2015) Retarded phase transition by fluorine doping in Li-rich layered Li1.2Mn0.54Ni0.13Co0.13O2 cathode material. J Power Sources 283:162–170. https://doi.org/10.1016/j.jpowsour.2015.02.085

Yu F-D, Que L-F, Wang Z-B, Zhang Y, Xue Y, Liu B-S, Gu D-M (2016) Layered-spinet capped nanotube assembled 3D Li-rich hierarchitectures for high performance Li-ion battery cathodes. J Mater Chem A 4(47):18416–18425. https://doi.org/10.1039/c6ta05676h

Wang J, Nie P, Xu G, Jiang J, Wu Y, Fu R, Dou H, Zhang X (2018) High-voltage LiNi0.45Cr0.1Mn1.45O4cathode with superlong cycle performance for wide temperature lithium-ion batteries. Adv Funct Mater 28(4):1704808. https://doi.org/10.1002/adfm.201704808

Bian X, Fu Q, Qiu H, Du F, Gao Y, Zhang L, Zou B, Chen G, Wei Y (2015) High-performance Li(Li0.18Ni0.15Co0.15Mn0.52)O-2@Li4M5O12 heterostructured cathode material coated with a lithium borate oxide glass layer. Chem Mater 27(16):5745–5754. https://doi.org/10.1021/acs.chemmater.5b02331

Luo K, Roberts MR, Guerrini N, Tapia-Ruiz N, Hao R, Massel F, Pickup DM, Ramos S, Liu Y-S, Guo J, Chadwick AV, Duda LC, Bruce PG (2016) Anion redox chemistry in the cobalt free 3d transition metal oxide intercalation electrode Li Li0.2Ni0.2Mn0.6 O-2. J Am Chem Soc 138(35):11211–11218. https://doi.org/10.1021/jacs.6b05111

Nayak PK, Penki TR, Markovsky B, Aurbach D (2017) Electrochemical performance of li- and mn-rich cathodes in full cells with prelithiated graphite negative electrodes. Acs Energy Lett 2(3):544–548. https://doi.org/10.1021/acsenergylett.7b00007

Zheng Y, Chen L, Su Y, Tan J, Bao L, Lu Y, Wang J, Chen R, Chen S, Wu F (2017) An interfacial framework for breaking through the Li-ion transport barrier of Li-rich layered cathode materials. J Mater Chem A 5(46):24292–24298. https://doi.org/10.1039/c7ta08735g

Luo D, Li G, Fu C, Zheng J, Fan J, Li Q, Li L (2014) A new spinel-layered li-rich microsphere as a high-rate cathode material for li-ion batteries. Adv Energy Mater 4(11):1400062. https://doi.org/10.1002/aenm.201400062

Zhang J, Lei Z, Wang J, NuLi Y, Yang J (2015) Surface modification of Li1.2Ni0.13Mn0.54Co0.13O2 by hydrazine vapor as cathode material for lithium-ion batteries. ACS Appl Mater Interfaces 7(29):15821–15829. https://doi.org/10.1021/acsami.5b02937

Zhao T, Li L, Chen S, Chen R, Zhang X, Lu J, Wu F, Amine K (2014) The effect of chromium substitution on improving electrochemical performance of low-cost Fe-Mn based Li-rich layered oxide as cathode material for lithium-ion batteries. J Power Sources 245:898–907. https://doi.org/10.1016/j.jpowsour.2013.07.026

Acknowledgements

This work is supported by the Science and Technology Plan Foundation of Guangzhou (201803030015), the Science and Technology Plan Foundation of Guangdong (2017B010119002) and the Science and Technology Plan Foundation of Foshan (1920001001421). Importantly, it is clear that we have no conflict of interest with the sponsors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, X., Zhang, Z., He, J. et al. Effects of chromium/fluorine co-doping on the electrochemical performance of Li1.2Ni0.13Co0.13Mn0.54O2 cathode material for lithium-ion batteries. J Mater Sci 56, 9836–9851 (2021). https://doi.org/10.1007/s10853-021-05922-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05922-1