Abstract

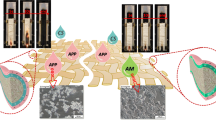

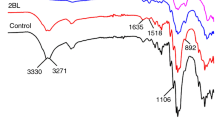

Flame retardant is essential for cotton fabric because of the restrictions in applications caused by poor flammability. Herein, a novel flame-retardant coating assembled on the surface of cotton fabric consists of polyethyleneimine/g-C3N4 and polyethyleneimine/phytic acid as the underlying insulating coating and the upper intumescent coating, respectively. Different amounts of the composite coatings were deposited onto the fabric by the layer-by-layer self-assembled technique. The char residue of TGA over 20 wt% has indicated the significantly enhanced performance of the thermal stability of all the coated samples and the achievement of the samples with composite coatings in a self-extinguished level proving through vertical combustion test. The samples prepared with binary hybrid coatings exhibited a high limiting oxygen index value of 30.5%. From the MCC test, the peak heat release rate and total heat release of (P/G + P/PA)4+4 showed a significant decrease of 76.9% and 77.1%, respectively. All these results demonstrated that the composite coatings endowed the cotton fabric with outstanding thermal stability and flame retardancy.

Similar content being viewed by others

References

Alongi J, Carosio F, Malucelli G (2014) Polym Degrad Stab 106:138–149. https://doi.org/10.1016/j.polymdegradstab.2013.07.012

Ammayappan L, Nayak LK, Ray DP, Das S, Roy AK (2013) J Nat Fibers 10:390–413. https://doi.org/10.1080/15440478.2013.824849

Li SH, Huang JY, Chen Z, Chen GQ, Lai YK (2017) J Mater Chem A 5:31–55. https://doi.org/10.1039/c6ta07984a

Weil ED (2011) J Fire Sci 29:259–296. https://doi.org/10.1177/0734904110395469

Norouzi M, Zare Y, Kiany P (2015) Polym Rev 55:531–560. https://doi.org/10.1080/15583724.2014.980427

Malucelli G, Carosio F, Alongi J, Fina A, Frache A, Camino G (2014) Mater Sci Eng R Rep 84:1–20. https://doi.org/10.1016/j.mser.2014.08.001

Holder KM, Smith RJ, Grunlan JC (2017) J Mater Sci 52:12923–12959. https://doi.org/10.1007/s10853-017-1390-1

Qiu X, Li Z, Li X, Zhang Z (2018) Chem Eng J 334:108–117. https://doi.org/10.1016/j.cej.2017.09.194

Li YC, Schulz J, Grunlan JC (2009) ACS Appl Mater Interfaces 1:2338–2347. https://doi.org/10.1021/am900484q

An Q, Huang T, Shi F (2018) Chem Soc Rev 47:5529. https://doi.org/10.1039/c8cs90072h

Carosio F, Laufer G, Alongi J, Camino G, Grunlan JC (2011) Polym Degrad Stab 96:745–750. https://doi.org/10.1016/j.polymdegradstab.2011.02.019

Chang S, Slopek RP, Condon B, Grunlan JC (2014) Ind Eng Chem Res 53:3805–3812. https://doi.org/10.1021/ie403992x

Costes L, Laoutid F, Brohez S, Dubois P (2017) Mater Sci Eng R-Rep 117:1–25. https://doi.org/10.1016/j.mser.2017.04.001

Lin D, Zeng X, Li H, Lai X (2018) Cellulose 25:3135–3149. https://doi.org/10.1007/s10570-018-1748-9

Idumah CI, Hassan A, Affam AC (2015) Rev Chem Eng 31:149–177. https://doi.org/10.1515/revce-2014-0038

Liu L, Huang Z, Pan Y, Wang X, Song L, Hu Y (2018) Cellulose 25:4791–4803. https://doi.org/10.1007/s10570-018-1866-4

Li S, Ding F, Lin X, Li Z, Ren X (2019) Fibers Polym 20:538–544. https://doi.org/10.1007/s12221-019-8914-z

Zhang Y, Tian W, Liu L et al (2019) Chem Eng J 372:1077–1090. https://doi.org/10.1016/j.cej.2019.05.012

Dasari A, Yu Z-Z, Cai G-P, Mai Y-W (2013) Prog Polym Sci 38:1357–1387. https://doi.org/10.1016/j.progpolymsci.2013.06.006

Lim KS, Bee ST, Sin LT et al (2016) Compos Pt B-Eng 84:155–174. https://doi.org/10.1016/j.compositesb.2015.08.066

Li YC, Mannen S, Morgan AB et al (2011) Adv Mater 23:3926–3931. https://doi.org/10.1002/adma.201101871

Shi X-H, Xu Y-J, Long J-W et al (2018) Chem Eng J 353:550–558. https://doi.org/10.1016/j.cej.2018.07.146

Pan H, Wang W, Pan Y et al (2015) Cellulose 22:911–923. https://doi.org/10.1007/s10570-014-0536-4

Laufer G, Kirkland C, Cain AA, Grunlan JC (2012) ACS Appl Mater Interfaces 4:1643–1649. https://doi.org/10.1021/am2017915

Koklukaya O, Carosio F, Wagberg L (2017) ACS Appl Mater Interfaces 9:29082–29092. https://doi.org/10.1021/acsami.7b08018

Huang G, Yang J, Gao J, Wang X (2012) Ind Eng Chem Res 51:12355–12366. https://doi.org/10.1021/ie301911t

Chai B, Yan J, Wang C, Ren Z, Zhu Y (2017) Appl Surf Sci 391:376–383. https://doi.org/10.1016/j.apsusc.2016.06.180

Jiang L, Yuan X, Pan Y et al (2017) Appl Catal B 217:388–406. https://doi.org/10.1016/j.apcatb.2017.06.003

Zhang J, Chen X, Takanabe K et al (2010) Angew Chem 49:441–444. https://doi.org/10.1002/anie.200903886

Fan Y, Zhou J, Zhang J et al (2018) Chem Phys Lett 699:146–154. https://doi.org/10.1016/j.cplett.2018.03.048

Wang Y, Ding X, Zhang P et al (2019) Ind Eng Chem Res 58:3978–3987. https://doi.org/10.1021/acs.iecr.8b05509

Luo B, Song R, Jing D (2017) Int J Hydrog Energy 42:23427–23436. https://doi.org/10.1016/j.ijhydene.2017.03.001

Fang H-B, Zhang X-H, Wu J, Li N, Zheng Y-Z, Tao X (2018) Appl Catal B 225:397–405. https://doi.org/10.1016/j.apcatb.2017.11.080

Guo S, Deng Z, Li M et al (2016) Angew Chem 55:1830–1834. https://doi.org/10.1002/anie.201508505

Zhang W, Fu Y, Liu W, Lim L, Wang X, Yu A (2019) Nano Energy 57:48–56. https://doi.org/10.1016/j.nanoen.2018.12.005

Zhao ZW, Sun YJ, Dong F (2015) Nanoscale 7:15–37. https://doi.org/10.1039/c4nr03008g

Shi Y, Wang B, Duan L et al (2016) Ind Eng Chem Res 55:7646–7654. https://doi.org/10.1021/acs.iecr.6b01237

Li R, Ren Y, Zhao P, Wang J, Liu J, Zhang Y (2019) J Hazard Mater 365:606–614. https://doi.org/10.1016/j.jhazmat.2018.11.033

Shi Y, Long Z, Yu B et al (2015) J Mater Chem A 3:17064–17073. https://doi.org/10.1039/c5ta04349b

Shi Y, Xing W, Wang B et al (2016) Mater Chem Phys 177:283–292. https://doi.org/10.1016/j.matchemphys.2016.04.029

Shi Y, Gui Z, Yu B, Yuen RKK, Wang B, Hu Y (2015) Compos B Eng 79:277–284. https://doi.org/10.1016/j.compositesb.2015.04.046

Zhu B, Xia P, Ho W, Yu J (2015) Appl Surf Sci 344:188–195. https://doi.org/10.1016/j.apsusc.2015.03.086

Zhu J, Xiao P, Li H, Carabineiro SA (2014) ACS Appl Mater Interfaces 6:16449–16465. https://doi.org/10.1021/am502925j

Yuan Y-P, Cao S-W, Liao Y-S, Yin L-S, Xue C (2013) Appl Catal B 140–141:164–168. https://doi.org/10.1016/j.apcatb.2013.04.006

Carosio F, Fontaine G, Alongi J, Bourbigot S (2015) ACS Appl Mater Interfaces 7:12158–12167. https://doi.org/10.1021/acsami.5b02507

Carosio F, Alongi J, Malucelli G (2012) Carbohyd Polym 88:1460–1469. https://doi.org/10.1016/j.carbpol.2012.02.049

Wang Y, Ding X, Chen X et al (2017) Cellulose 24:4569–4580. https://doi.org/10.1007/s10570-017-1445-0

New J, Zope IS, Abdul Rahman SN, Yap XLW, Dasari A (2016) Mater Design 89:413–420. https://doi.org/10.1016/j.matdes.2015.10.006

Zhang T, Yan H, Shen L et al (2014) Ind Eng Chem Res 53:19199–19207. https://doi.org/10.1021/ie503421f

Xue B, Chen Y, Hong Y, Ma DY, Xu J, Li YX (2018) Chin J Catal 39:1263–1271. https://doi.org/10.1016/s1872-2067(18)63063-3

Pan Y, Liu L, Zhang Y et al (2019) Carbohyd Polym 206:396–402. https://doi.org/10.1016/j.carbpol.2018.11.037

Pan H, Wang W, Pan Y, Song L, Hu Y, Liew KM (2015) Carbohyd Polym 115:516–524. https://doi.org/10.1016/j.carbpol.2014.08.084

Wang W, Guo J, Liu X et al (2020) Cellulose 27:5377–5389. https://doi.org/10.1007/s10570-020-03140-7

Pan Y, Zhan J, Pan H et al (2016) ACS Sustain Chem Eng 4:1431–1438

Wang J, He J, Ma L et al (2020) Chem Eng J 390:124508

Acknowledgments

This work is supported by the ministry of education of China and the Gansu Provincial Development and Reform Commission.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors have no conflict of interest to declare.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, Z., Zhang, Z. & Wang, Y. A novel efficient nonflammable coating containing g-C3N4 and intumescent flame retardant fabricated via layer-by-layer assembly on cotton fiber. J Mater Sci 56, 9678–9691 (2021). https://doi.org/10.1007/s10853-021-05877-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05877-3