Abstract

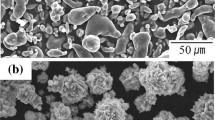

The vulnerability of weapon and ammunition has been attracting more and more researcher’s attention in order to improve their system survival in battlefield and security of production, transport and service management, and to adapt to the harsh battlefield environment. One of potential directions of explosive research and development is to reduce its vulnerability through charging structures. RDX-based high aluminized gradient structures explosives are constructed via direct ink writing. SEM and DSC demonstrated good compatibility of the gradient explosives and no significant gaps at the interface of the filaments, which leads to good thermal stability and suppressed hot spot formation within the gradient explosive. The critical dimension of detonation indicates that the critical size of explosive with gradient structure is greatly increased. This attractive integration of structural and functional advantages achieved by 3D printing gradient structure process offers new insights into the design of robust munitions.

Similar content being viewed by others

References

Naebe M, Shirvanimoghaddam K (2016) Functionally graded materials: a review of fabrication and properties. Appl Mater Today 5:223–245. https://doi.org/10.1016/j.apmt.2016.10.001

Zhang C, Chen F, Huang Z, Jia M, Chen G, Ye Y, Lin Y, Liu W, Chen B, Shen Q, Zhang L, Lavernia EJ (2019) Additive manufacturing of functionally graded materials: a review. Mater Sci Eng A 764:138209. https://doi.org/10.1016/j.msea.2019.138209

Prikhodko SV, Ivasishin OM, Markovsky PE, Savvakin DG, Stasiuk OO (2020) Advanced technologies for security applications. Springer, New York, pp 127–140

Bukovsky EV, Reeves RV, Krish A, Gash AE, Glumac NG (2018) Experimental study of structure/behavior relationship for a metallized explosive . AIP Conf Proc. https://doi.org/10.1063/1.5044962

Liang B, Lin Z, Chen W, He Z, Zhong J, Zhu H, Tang Z, Gui X (2018) Ultra-stretchable and highly sensitive strain sensor based on gradient structure carbon nanotubes. Nanoscale 10:13599–13606. https://doi.org/10.1039/c8nr02528b

Kokubo N, Arake M, Yamagishi K, Morimoto Y, Takeoka S, Ohta H, Fujie T (2018) Inkjet-printed neural electrodes with mechanically gradient structure. ACS Appl Bio Mater 2:20–26. https://doi.org/10.1021/acsabm.8b00574

Nie T, Xue L, Ge M, Ma H, Zhang J (2016) Fabrication of poly(L-lactic acid) tissue engineering scaffolds with precisely controlled gradient structure. Mater Lett 176:25–28. https://doi.org/10.1016/j.matlet.2016.04.078

Peng M, Wen Z, Xie L, Cheng J, Jia Z, Shi D, Zeng H, Zhao B, Liang Z, Li T, Jiang L (2019) 3D printing of ultralight biomimetic hierarchical graphene materials with exceptional stiffness and resilience. Adv Mater 31:1902930. https://doi.org/10.1002/adma.201902930

Hindy A, Farahmand F, Pourdanesh F, Torshabi M, Al Janabi AH, Rasoulianboroujeni M, Tayebi L, Tabatabaei FS (2020) Synthesis and characterization of 3D-printed functionally graded porous titanium alloy. J Mater Sci 55:9082–9094. https://doi.org/10.1007/s10853-020-04645-z

Bruck HA, Gallant FM, Gowrisankaran SR (2003) Fabrication and design of multifunctional energetic structures using gradient architectures . ASME 2003 Int Mech Eng Congress and Exposit Am Soc Mecha Eng Digit Collect. https://doi.org/10.1115/IMECE2003-43328

Xiao-feng W (2011) Developmental Trends in Military Composite Explosive. Chinese J Explos Propellants, 34:1–9 https://doi.org/10.14077/j.issn.1007-7812.2011.04.019

Yan Q-L, Zeman S, Elbeih A (2012) Recent advances in thermal analysis and stability evaluation of insensitive plastic bonded explosives (PBXs). Thermochim Acta 537:1–12. https://doi.org/10.1016/j.tca.2012.03.009

Kumar AS, Rao VB, Sinha RK, Rao AS (2009) Evaluation of Plastic bonded explosive (PBX) formulations based on RDX, aluminum, and HTPB for underwater applications. Propellants Explos Pyrotech 35:359–364. https://doi.org/10.1002/prep.200800048

Lu JP, Lochert IJ, Daniel MA, Franson MD (2016) Shock sensitivity studies for PBXN-109. Propellants Explos Pyrotech 41:562–571. https://doi.org/10.1002/prep.201500336

Siviour CR, Gifford MJ, Walley SM, Proud WG, Field JE (2004) Particle size effects on the mechanical properties of a polymer bonded explosive. J Mater Sci 39:1255–1258. https://doi.org/10.1023/B:JMSC.0000013883.45092.45

Elbeih A, Jungová M, Zeman S, Vávra P, Akštein Z (2012) Explosive strength and impact sensitivity of several PBXs based on attractive cyclic nitramines. Propellants Explos Pyrotech 37:329–334. https://doi.org/10.1002/prep.201100020

Liu J-y, Dong Y-x, An X-y, Ye P, Sun Q-t, Gao Q (2020) Reaction degree of composition B explosive with multi-layered compound structure protection subjected to detonation loading. Def Technol . https://doi.org/10.1016/j.dt.2020.1002.1004.10.1016/j.dt.2020.02.004

Drodge DR, Williamson DM (2015) Understanding damage in polymer-bonded explosive composites. J Mater Sci 51:668–679. https://doi.org/10.1007/s10853-013-7378-6

Chortos A, Hajiesmaili E, Morales J, Clarke DR, Lewis JA (2019) 3D printing of interdigitated dielectric elastomer actuators. Adv Funct Mater 29:1907375. https://doi.org/10.1002/adfm.201907375

Orangi J, Hamade F, Davis VA, Beidaghi M (2020) 3D printing of additive-free 2D Ti3C2Tx (MXene) Ink for fabrication of micro-supercapacitors with ultra-high energy densities. ACS Nano 14:640–650. https://doi.org/10.1021/acsnano.9b07325

Xue J, Gao L, Hu X, Cao K, Zhou W, Wang W, Lu Y (2019) Stereolithographic 3D printing-based hierarchically cellular lattices for high-performance quasi-solid supercapacitor. Nanomicro Lett 11:46. https://doi.org/10.1007/s40820-019-0280-2

Muravyev NV, Monogarov KA, Schaller U, Fomenkov IV, Pivkina AN (2019) Progress in additive manufacturing of energetic materials: creating the reactive microstructures with high potential of applications. Propellants Explos Pyrotech 44:941–969. https://doi.org/10.1002/prep.201900060

Chandru RA, Balasubramanian N, Oommen C, Raghunandan BN (2018) Additive manufacturing of solid rocket propellant grains. J Propul Power 34:1090–1093. https://doi.org/10.2514/1.B36734

Zhang L, Zhang F, Wang Y, Han R, Chen J, Zhang R, Chu E (2019) In-situ preparation of copper azide by direct ink writing. Mater Lett 238:130–133. https://doi.org/10.1016/j.matlet.2018.11.165

Wang D, Zheng B, Guo C, Gao B, Wang J, Yang G, Huang H, Nie F (2016) Formulation and performance of functional sub-micro CL-20-based energetic polymer composite ink for direct-write assembly. RSC Adv 6:112325–112331. https://doi.org/10.1039/c6ra22205f

Mao Y, Zhong L, Zhou X, Zheng D, Zhang X, Duan T, Nie F, Gao B, Wang D (2019) 3D printing of micro-architected Al/CuO-based nanothermite for enhanced combustion performance. Adv Eng Mater 21:1900825. https://doi.org/10.1002/adem.201900825

Lewis JA (2006) Direct Ink writing of 3D functional materials. Adv Funct Mater 16:2193–2204. https://doi.org/10.1002/adfm.200600434

Beheshtizadeh N, Lotfibakhshaiesh N, Pazhouhnia Z, Hoseinpour M, Nafari M (2019) A review of 3D bio-printing for bone and skin tissue engineering: a commercial approach. J Mater Sci 55:3729–3749. https://doi.org/10.1007/s10853-019-04259-0

Shuai X, Zeng Y, Li P, Chen J (2020) Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. J Mater Sci 55:6771–6782. https://doi.org/10.1007/s10853-020-04503-y

Dunju W, Changping G, Ruihao W, Baohui Z, Bing G, Fude N (2019) Additive manufacturing and combustion performance of CL-20 composites. J Mater Sci 55:2836–2845. https://doi.org/10.1007/s10853-019-04209-w

Hu Y, Yuan S, Li X, Liu M, Sun F, Yang Y, Hao G, Jiang W (2020) Preparation and characterization of nano-CL-20/TNT cocrystal explosives by mechanical ball-milling method. ACS Omega 5:17761–17766. https://doi.org/10.1021/acsomega.0c02426

Ruz-Nuglo F, Groven L, Puszynski JAr (2014) Additive Manufacturing for Energetic Components and Materials. https://doi.org/10.2514/6.2014-3894

He K (1957) Reaction kinetics in different thermal analysis. Anal Chem 29:1702–1706

Blaine RL, Kissinger HE (2012) Homer kissinger and the kissinger equation. Thermochim Acta 540:1–6. https://doi.org/10.1016/j.tca.2012.04.008

772A-97 G (1997) Method 502.1: stability and compatibility — method of differential thermal analysis and differential scanning calorimetry Beijing, China: National Defense Science, Technology and Industry Committee, 159

Xu C, An C, Long Y, Li Q, Guo H, Wang S, Wang J (2018) Inkjet printing of energetic composites with high density. RSC Adv 8:35863–35869. https://doi.org/10.1039/c8ra06610h

Hussain G, Rees GJ (1995) Thermal decomposition of RDX and mixtures. Fule 74:273–277. https://doi.org/10.1016/0016-2361(95)92665-S

Abd-Elghany M, Elbeih A, Hassanein S (2016) Thermal behavior and decomposition kinetics of RDX and RDX/HTPB composition using various techniques and Methods. Cent Eur J Energ Mater, 13:714–735. https://doi.org/10.22211/cejem/64954

Liu R, Yang L, Zhou Z, Zhang T (2013) Thermal stability and sensitivity of RDX-based aluminized explosives. J Therm Anal Calorim 115:1939–1948. https://doi.org/10.1007/s10973-013-3468-6

Sweeney M, Campbell LL, Hanson J, Pantoya ML, Christopher GF (2017) Characterizing the feasibility of processing wet granular materials to improve rheology for 3D printing. J Mater Sci 52:13040–13053. https://doi.org/10.1007/s10853-017-1404-z

Courtial E-J, Perrinet C, Colly A, Mariot D, Frances J-M, Fulchiron R, Marquette C (2019) Silicone rheological behavior modification for 3D printing: evaluation of yield stress impact on printed object properties. Addit Manufact 28:50–57. https://doi.org/10.1016/j.addma.2019.04.006

Woods H, Boddorff A, Ewaldz E, Adams Z, Ketcham M, Jang DJ, Sinner E, Thadhani N, Brettmann B (2019) Rheological Considerations for binder development in direct ink writing of energetic materials. Propellants Explos Pyrotech 45:26–35. https://doi.org/10.1002/prep.201900159

M’Barki A, Bocquet L, Stevenson A (2017) Linking rheology and printability for dense and strong ceramics by direct ink writing. Sci Rep 7:6017. https://doi.org/10.1038/s41598-017-06115-0

Zeng L, Jiaq Q-j, Ren H, Zhou Q (2011) Experimental study on the secondary reaction time of aluminized explosive. Initiat Pyrotech 2:19–23

Chen Lang LX-p, Feng Chang-gen, Jiang Xiao-hua (2004) Explosive detonation with aluminum. Beijing: Ordnance Industry Press,

Prakash V, Phadke VK, Sinha RK, Singh H (2004) Influence of aluminium on performance of HTPB-based aluminised PBXs. Def Sci J 54:475–482. https://doi.org/10.14429/dsj.54.2061

Acknowledgements

This work was supported and funded by Longshan Academic Talent Research Support Program of SWUST China, the Natural Science Foundation of China (No. 17LZX509, No. 18LZX684, No. 11602239, and 11872341), National Training Program of Innovation and Entrepreneurship for Undergraduates (No. S201910619027). The authors also thank the continuous support from Pine Ridge Laboratory of Advanced Materials, Sichuan Easy Scientific Research Community Technology Co., Ltd., Mianyang 621050 China.

Funding

This study was funded by any institute Natural Science Foundation of China (No. 17LZX509, No. 18LZX684, No. 11602239, and 11872341), National Training Program of Innovation and Entrepreneurship for Undergraduates (No. S201910619027).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Dale Huber.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Zhou, X., Mao, Y., Zheng, D. et al. 3D printing of RDX-based aluminized high explosives with gradient structure, significantly altering the critical dimensions. J Mater Sci 56, 9171–9182 (2021). https://doi.org/10.1007/s10853-021-05869-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05869-3