Abstract

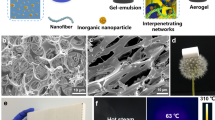

Glass microballoons (GMBs) are commonly used to reduce the density of epoxy-resin syntactic foams, but they can also be applied as a low-cost and lightweight catalyst support. In order to create a practical structure that can be utilized for such an application, a ceramic syntactic foam consisting of glass microballoons (GMBs) and silica nanofibers (NFs) with or without TiO2 binder was synthesized. The mechanical strength, phase composition, high-temperature deformation behavior, and microstructure of the composite material were analyzed using bending and compression tests, X-ray diffraction, and scanning electron microscopy, respectively. It was determined that the addition of nanofibers improves the thermal behavior and mechanical strength of the composite material during and after processing. The composite materials maintained up to 70% anatase titania at as high as 700 °C, and this indicates that they can be of interest for high-temperature catalysis. No high-temperature deformation of GMBs was observed at 800 °C or 1000 °C, whereas XRD of samples coated with TiO2 using a titanium oxysulfate solution indicated the formation of cristobalite above 800 °C. Preliminary methane-reforming experiments were performed with NiO-seeded titania-coated GMBs, uncoated GMBs, and an uncoated silica fibers/GMBs composite. Uncoated GMBs and titania-coated GMBs had a low conversion ratio of methane to products, but the uncoated composite structure showed high conversion of the reactants at high temperatures, indicating that it may be suitable catalyst support in this reaction.

Similar content being viewed by others

References

Brown JA, Carroll JD, Huddleston B, Casias Z, Long KN (2018) A multiscale study of damage in elastomeric syntactic foams. J Mater Sci 53(14):10479–10498

Jayavardhan ML, Doddamani M (2018) Quasi-static compressive response of compression molded glass microballoon/HDPE syntactic foam. Compos B Eng 149:165–177

Panteghini A, Bardella L (2015) On the compressive strength of glass microballoons-based syntactic foams. Mech Mater 82:63–77

Dimchev M, Caeti R, Gupta N (2010) Effect of carbon nanofibers on tensile and compressive characteristics of hollow particle filled composites. Mater Des 31(3):1332–1337

Koopman M, Chawla K, Ricci W, Carlisle K, Gladsyz G, Lalor M, Jones M, Kerr K et al (2009) Titania-coated glass microballoons and cenospheres for environmental applications. J Mater Sci 44(6):1435–1441

Yao H, Xie Y, Jing Y, Wang Y, Luo G (2017) Controllable preparation and catalytic performance of heterogeneous fenton-like α-Fe2O3/crystalline glass microsphere catalysts. Ind Eng Chem Res 56(46):13751–13759

An Y, Zheng P, Ma X (2019) Preparation and visible-light photocatalytic properties of the floating hollow glass microspheres—TiO2/Ag3PO4 composites. RSC Adv 9(2):721–729

Cheng B, Chen X, Wang X, Qiu H, Qi S (2017) Preparation and microwave absorbing performance of TiO2/ NiFe2O4 /hollow glass microsphere composite with core–shell structure. J Mater Sci Mater Electron 28(11):7575–7581

Guo X, Sun Y, Yu Y, Zhu X, Liu C-J (2012) Carbon formation and steam reforming of methane on silica supported nickel catalysts. Catal Commun 19:61–65

Amin MH (2020) Relationship between the pore structure of mesoporous silica supports and the activity of nickel nanocatalysts in the CO2 reforming of methane. Catalysts (2073–4344) 10(1):51

Ye R-P, Gong W, Sun Z, Sheng Q, Shi X, Wang T, Yao Y, Razink JJ et al (2019) Enhanced stability of Ni/SiO2 catalyst for CO2 methanation: Derived from nickel phyllosilicate with strong metal-support interactions. Energy 188:116059

Tao M, Meng X, Lv Y, Bian Z, Xin Z (2016) Effect of impregnation solvent on Ni dispersion and catalytic properties of Ni/SBA-15 for CO methanation reaction. Fuel 165:289–297

Matsumura Y, Nakamori T (2004) Steam reforming of methane over nickel catalysts at low reaction temperature. Appl Catal A 258(1):107–114

Rodemerck U, Schneider M, Linke D (2017) Improved stability of Ni/SiO2 catalysts in CO2 and steam reforming of methane by preparation via a polymer-assisted route. Catal Commun 102:98–102

John B, Reghunadhan Nair CP (2014) 13-Syntactic foams, in handbook of thermoset plastics (Third Edition), In: Dodiuk H, Goodman SH (Eds.) William Andrew Publishing: Boston. pp 511–554

Zhang L, Ma J (2013) Effect of carbon nanofiber reinforcement on mechanical properties of syntactic foam. Mater Sci Eng A 574:191–196

Colloca M, Gupta N, Porfiri M (2013) Tensile properties of carbon nanofiber reinforced multiscale syntactic foams. Compos B Eng 44(1):584–591

Ullas AV, Qayyum B, Kumar D, Roy PK (2016) Electrospun polyamide nanofiber-reinforced hybrid syntactic foams. Polym Plastics Technol Eng 55(17):1797–1806

He S, Carolan D, Fergusson A, Taylor AC (2019) Toughening epoxy syntactic foams with milled carbon fibres: mechanical properties and toughening mechanisms. Mater Des 169:107654

Karthikeyan CS, Sankaran S, Kishore (2000) Influence of chopped strand fibres on the flexural behaviour of a syntactic foam core system. Polym Int 49(2):158–162

Karthikeyan CS, Sankaran S, Jagdish Kumar MN, Kishore (2001) Processing and compressive strengths of syntactic foams with and without fibrous reinforcements. J Appl Polym Sci 81(2):405–411

Karthikeyan CS, Sankaran S, Kishore (2004) Elastic behaviour of plain and fibre-reinforced syntactic foams under compression. Mater Lett 58(6):995–999

Karthikeyan CS, Sankaran S, Kishore (2005) Flexural behaviour of fibre-reinforced syntactic foams. Macromol Mater Eng 290(1):60–65

Stanishevsky A, Tchernov J (2019) Mechanical and transport properties of fibrous amorphous silica meshes and membranes fabricated from compressed electrospun precursor fibers. J Non Cryst Solids 525:119653

Wang H, Jiao C, Zhao L, Chen X (2018) Preparation and characterization of TiO2-coated hollow glass microsphere and its flame-retardant property in thermoplastic polyurethane. J Therm Anal Calorim 131(3):2729–2740

Alaoui AH, Woignier T, Scherer GW, Phalippou J (2008) Comparison between flexural and uniaxial compression tests to measure the elastic modulus of silica aerogel. J Non Cryst Solids 354(40):4556–4561

Herrmann J-M (1999) Heterogeneous photocatalysis: fundamentals and applications to the removal of various types of aqueous pollutants. Catal Today 53(1):115–129

Mohamedali M, Amr H, Ibrahim H (2018) Recent advances in supported metal catalysts for syngas production from methane. ChemEngineering 2(1):9

Kho ET, Scott J, Amal R (2016) Ni/TiO2 for low temperature steam reforming of methane. Chem Eng Sci 140:161–170

Ali S, Al-Marri MJ, Abdelmoneim AG, Kumar A, Khader MM (2016) Catalytic evaluation of nickel nanoparticles in methane steam reforming. Int J Hydrogen Energy 41(48):22876–22885

Acknowledgements

This work has been supported in part by the National Science Foundation (NSF) [Grant Number DMR-1708600]. MA, SN, and CS thank the support from the NSF International Research Experience for Students (IRES) Program [Grant Number OISE-1558268].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no relationships or interests of the authors of this work that may bias the results of this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Armstrong, M., Nealy, S., Severino, C. et al. Composite materials made from glass microballoons and ceramic nanofibers for use as catalysts and catalyst supports. J Mater Sci 55, 12940–12952 (2020). https://doi.org/10.1007/s10853-020-04956-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04956-1