Abstract

Intelligent breathable membranes with multiple functions attach wide attentions of people which provide protection and comfort to meet the pressing demand for future protective clothing. We proposed a novel thermal energy regulated and thermochromic composite film with temperature-sensitive “breathable” stomata consisted of thermochromic nanofibrous membrane (TC-NFM) and thermo-sensitive polyurethane (PU) film. Thermochromic nanoencapsulated phase change materials (TC-NPCMs) were introduced as functional fillers into polyvinyl alcohol/water-soluble polyurethane (PVA/WPU) solution for electrospinning process. And methylated melamine–formaldehyde (MMF) was innovatively used to modify the water resistance of TC-NFM. By adjusting the molecular weight of the soft segment, the thermo-sensitive PU film was successfully prepared. Consequently, the prepared TC-NFM exhibited high enthalpy of 44.3 J g−1 and kept superior energy storage and release property even after 100th cyclic experiments. The water vapor permeability of thermo-sensitive PU film was triggered near the comfortable temperature of the human body. The results presented here might facilitate improvements in the field of thermal regulation clothing, intelligent clothing, wearable temperature sensor and reversible thermochromic coating materials.

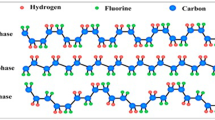

Graphic abstract

Similar content being viewed by others

References

Gonzalez J, Lacal-Arantegui R (2016) A review of regulatory framework for wind energy in European Union countries: current state and expected developments. Renew Sustain Energy Rev 56:588–602

Sahu B (2018) Wind energy developments and policies in China: a short review. Renew Sustain Energy Rev 81:1393–1405

Khare V, Nema S, Baredar P (2016) Solar-wind hybrid renewable energy system: a review. Renew Sustain Energy Rev 58:23–33

Trenchard H, Perc M (2016) Energy saving mechanisms, collective behavior and the variation range hypothesis in biological systems: a review. BioSystems 147:40–66

Sharon H, Reddy K (2015) A review of solar energy driven desalination technologies. Renew Sustain Energy Rev 41:1080–1188

Tian Y, Zhao C (2013) A review of solar collectors and thermal energy storage in solar thermal applications. Appl Energy 104:538–553

Modi A, Buhler F, Andreasen J, Haglind F (2017) A review of solar energy based heat and power generation systems. Renew Sustain Energy Rev 67:1047–1064

Rashidi S, Esfahani J, Rashidi A (2017) A review on the applications of porous materials in solar energy systems. Renew Sustain Energy Rev 73:1198–1210

Khan N, Kalair A, Abas N, Haider A (2017) Review of ocean tidal, wave and thermal energy technologies. Renew Sustain Energy Rev 72:590–604

Khan Z, Khan Z, Ghafoor A (2016) A review of performance enhancement of PCM based latent heat storage system within the context of materials, thermal stability and compatibility. Energy Convers Manage 115:132–158

Mavrigiannaki A, Ampatzi E (2016) Latent heat storage in building elements: a systematic review on properties and contextual performance factors. Renew Sustain Energy Rev 60:852–866

Pointner H, de Gracia A, Vogel J, Tay N, Liu M, Johnson M et al (2016) Computational efficiency in numerical modeling of high temperature latent heat storage: comparison of selected software tools based on experimental data. Appl Energy 161:337–348

Gao H, Wang J, Chen X, Wang G, Huang X, Li A et al (2018) Nanoconfinement effects on thermal properties of nanoporous shape-stabilized composite PCMs: a review. Nano Energy 53:769–797

Giro-Paloma J, Martinez M, Cabeza L, Fernandez A (2016) Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): a review. Renew Sustain Energy Rev 53:1059–1075

Jurkowska M, Szczygiel I (2016) Review on properties of microencapsulated phase change materials slurries (mPCMS). Appl Therm Eng 98:365–373

Sari A, Alkan C, Bicer A, Altuntas A, Bilgin C (2014) Micro/nanoencapsulated n-nonadecane with poly(methyl methacrylate) shell for thermal energy storage. Energy Convers Manage 86:614–621

Li W, Zhang X, Wang X, Tang G, Shi H (2012) Fabrication and morphological characterization of microencapsulated phase change materials (MicroPCMs) and macrocapsules containing MicroPCMs for thermal energy storage. Energy 38:249e54

Zhang H, Wang X (1366e) Synthesis and properties of microencapsulated n-octadecane with polyurea shells containing different soft segments for heat energy storage and thermal regulation. Sol Energy Mater Sol Cells 93:1366e76

Li W, Zhang X, Wang X, Niu J (2007) Preparation and characterization of microencapsulated phase change material with low remnant formaldehyde content. Mater Chem Phys 106:437–442

Lei H, Fu C, Zou Y, Guo S, Huo J (2019) Thermal energy storage composite with sensing function and its thermal conductivity and thermal effusivity enhancement. J Mater Chem A 7:6720–6729

Geng X, Li W, Wang Y, Lu J, Wang J, Wang N et al (2018) Reversible thermochromic microencapsulated phase change materials for thermal energy storage application in thermal protective clothing. Appl Energy 217:281–294

Davis D, Hamilton A, Yang J, Cremar L, Van Gough D, Potisek S et al (2009) Force-induced activation of covalent bonds in mechanoresponsive polymeric materials. Nature 459:68–72

Gao Y, Luo H, Zhang Z, Kang L, Chen Z, Du J et al (2012) Nanoceramic VO2 thermochromic smart glass: a review on progress in solution processing. Nano Energy 1:221–246

Luo X, Li J, Li C, Heng L, Dong Y, Liu Z et al (2011) Reversible switching of the emission of diphenyldibenzofulvenes by thermal and mechanical stimuli. Adv Mater 23:3261–3265

Zhang W, Ji X, Zeng C, Chen K, Yin Y, Wang C (2017) A new approach for the preparation of durable and reversible color changing polyester fabrics using thermochromic leuco dye-loaded silica nanocapsules. J Mater Chem C 5:8169–8178

Powell M, Quesada-Cabrera R, Taylor A, Teixeira D, Papakonstantinou I, Palgrave R et al (2016) Intelligent multifunctional VO2/SiO2/TiO2 coatings for self-cleaning, energy-saving window panels. Chem Mater 28:1369–1376

Kim H, Kim Y, Kim K, Jeong H, Jang A, Han S et al (2013) Flexible Thermochromic window based on hybridized VO2/graphene. ACS Nano 3:5769–5776

Kulcar R, Friskovec M, Hauptman N, Vesel A, Gunde M (2010) Colorimetric properties of reversible thermochromic printing inks. Dyes Pigm 86:271–277

He Y, Li W, Han N, Wang J, Zhang X (2019) Facile flexible reversible thermochromic membranes based on micro/nanoencapsulated phase change materials for wearable temperature sensor. Appl Energy 247:615–629

Xu J, Liu C, Hsu P, Liu K, Zhang R, Liu Y et al (2016) Roll-to-roll transfer of electrospun nanofiber Film for high-efficiency transparent air filter. Nano Lett 16:1270–1275

Liu C, Hsu P, Lee H, Ye M, Zheng G, Liu N et al (2015) Transparent air filter for high-efficiency PM 2.5 capture. Nat Commun. 6:6205

Lv D, Zhu M, Jiang Z, Jiang S, Zhang Q, Xiong R et al (2018) Green electrospun nanofibers and their application in air filtration. Macromol Mater Eng 303:1800336

Sambaer W, Zatloukal M, Kimmer D (2011) 3D modeling of filtration process via polyurethane nanofiber based nonwoven filters prepared by electrospinning process. Chem Eng Sci 66:613–623

Zhu M, Hua D, Pan H, Wang F, Manshian B, Soenen S et al (2018) Green electrospun and crosslinked poly(vinyl alcohol)/poly(acrylic acid) composite membranes for antibacterial effective air filtration. J Colloid Interface Sci 511:411–423

Lv D, Wang R, Tang G, Mou Z, Lei J, Han J et al (2019) Ecofriendly electrospun membranes loaded with visible-light-responding nanoparticles for multifunctional usages: highly efficient air filtration, dye scavenging, and bactericidal activity. ACS Appl Mater Interfaces 11:12880–12889

Bolto B, Tran T, Hoang M, Xie Z (2009) Crosslinked poly(vinyl alcohol) membranes. Prog Polym Sci 34:969–981

Zhao G, Liu Y, Fang C, Zhang M, Zhou C, Chen Z (2006) Water resistance, mechanical properties and biodegradability of methylated-cornstarch/poly(vinyl alcohol) blend film. Polym Degrad Stab 91:703–711

Rother M, Barmettler J, Reichmuth A, Araujo J, Rytka C, Glaied O et al (2015) Self-sealing and puncture resistant breathable membranes for water-evaporation applications. Adv Mater 27:6620–6624

Fornasiero F (2017) Water vapor transport in carbon nanotube membranes and application in breathable and protective fabrics. Curr Opin Chem Eng 16:1–8

Lin Y, Zhu C, Alva G, Fang G (2018) Palmitic acid/polyvinyl butyral/expanded graphite composites as form-stable phase change materials for solar thermal energy storage. Appl Energy 228:1801–1809

Mondal S, Hu J (2006) Structural characterization and mass transfer properties of nonporous segmented polyurethane membrane: Influence of hydrophilic and carboxylic group. J Membr Sci 274:219–226

Zhong X, Li R, Wang Z, Wang W, Yu D (2019) Titanium dioxide/quaternary phosphonium salts/polyacrylonitrile composite nanofibrous membranes with high antibacterial properties and ultraviolet resistance efficiency. J Mater Sci 54:13322–13333

Chattopadhyay D, Raju K (2007) Structural engineering of polyurethane coatings for high performance applications. Prog Polym Sci 32:352–418

Kim H, Miura Y, Macosko C (2010) Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem Mater 22:3441–3450

Cavaliere S, Subianto S, Savych I, Jones D, Roziere J (2011) Electrospinning: designed architectures for energy conversion and storage devices. Energy Environ Sci 4:4761–4785

Li Y, Yu S, Chen P, Rojas R, Hajian A, Berglund L (2017) Cellulose nanofibers enable paraffin encapsulation and the formation of stable thermal regulation nanocomposites. Nano Energy 34:541–548

Chen C, Chen J, Jia Y, Topham P, Wang L (2018) Binary shape-stabilized phase change materials based on poly(ethylene glycol)/polyurethane composite with dual-phase transition. J Mater Sci 53:16539–16556

Liang B, Lu X, Li R, Tu W, Yang Z, Yuan T (2019) Solvent-free preparation of bio-based polyethylene glycol/wood flour composites as novel shape-stabilized phase change materials for solar thermal energy storage. Sol Energy Mater Sol Cells 200:110037

Acknowledgements

The authors gratefully acknowledge the financial supports for this research from the National Natural Science Foundation of China (No.51573135) and Tianjin Research Program of Application Foundation and Advanced Technology (No. 16JCYBJC17100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, Y., Sun, S., Han, N. et al. Thermal energy regulated and thermochromic composite film with temperature-sensitive “breathable” stomata. J Mater Sci 55, 12921–12939 (2020). https://doi.org/10.1007/s10853-020-04936-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04936-5