Abstract

Methods are presented determining the Gibbs triple junction excess (\({\varGamma }^{\text{TJ}}\)) of solute segregation in polycrystalline materials from single atom counting in 3D volumes. One method bases on cumulative profile analysis, while two further methods use radial integration of solute atoms. The methods are demonstrated and compared on simulated model volumes which include three grain boundaries joining together at a triple junction with set values for Gibbs grain boundary and triple junction excess. An experimental technique that provides 3D volumes with single atom detection and spatial resolution close to atomic scale is atom probe tomography. An atom probe tomography volume of a \(\hbox {CoSi}_2\) thin film that contains three grain boundaries and a triple junction has been acquired. Ti segregation is found qualitatively at the grain boundaries and triple junction. The quantification of the Ti excess at the investigated \(\hbox {CoSi}_2\) triple junction reveals for the three introduced methods positive Gibbs triple junction excess values. It demonstrates that there is an excess of Ti at \(\hbox {CoSi}_2\) triple junctions and provides opportunities for its quantification.

Similar content being viewed by others

References

King AH (1999) The geometric and thermodynamic properties of grain boundary junctions. Interface Sci 7:251–271

Taylor JE (1999) Mathematical models of triple junctions. Interface Sci 7:243–249

Caro A, Van Swygenhoven H (2001) Grain boundary and triple junction enthalpies in nanocrystalline metals. Phys Rev B 63(13):134101

Gottstein G, Shvindlerman LS, Zhao B (2010) Thermodynamics and kinetics of grain boundary triple junctions in metals: recent developments. Scr Mater 62(12):914–917

Fortier P, Palumbo G, Bruce GD, Miller WA, Aust KT (1991) Triple line energy determination by scanning tunneling microscopy. Scr Metall Mater 25(1):177–182

Zhao B, Ch Verhasselt J, Shvindlerman LS, Gottstein G (2010) Measurement of grain boundary triple line energy in copper. Acta Mater 58(17):5646–5653

Srinivasan SG, Cahn JW, Jónsson H, Kalonji G (1999) Excess energy of grain-boundary trijunctions: an atomistic simulation study. Acta Mater 47(9):2821–2829

Eich SM, Schmitz G (2016) Embedded-atom study of low-energy equilibrium triple junction structures and energies. Acta Mater 109:364–374

King AH (2007) Triple junction energy and prospects for measuring it. Mater Sci Technol 23(5):505–508

Yin KM, King AH, Hsieh TE (1997) Segregation of bismuth to triple junctions in copper. Microsc Microanal 3(5):417–422

Tian J, Chiu YL (2019) Study the grain boundary triple junction segregation of phosphorus in a nickel-base alloy using energy dispersive X-ray spectroscopy on a transmission electron microscope. Mater Charact 148(December 2018):156–161

Kim H, Xuan Y, Ye PD, Narayanan R, King AH (2009) Anomalous triple junction surface pits in nanocrystalline zirconia thin films and their relationship to triple junction energy. Acta Mater 57(12):3662–3670

Gault B, Moody MP, Cairney JM, Ringer SP (2012) Atom probe microscopy. Springer, Berlin

Lefebvre W, Vurpillot F, Sauvage X (2016) Atom probe tomography: put theory into practice. Elsevier, Amsterdam

Chellali MR, Balogh Z, Zheng L, Schmitz G (2011) Triple junction and grain boundary diffusion in the Ni/Cu system. Scr Mater 65(4):343–346

Chellali MR, Balogh Z, Bouchikhaoui H, Schlesiger R, Stender P, Zheng L, Schmitz G (2012) Triple junction transport and the impact of grain boundary width in nanocrystalline Cu. Nano Lett 12(7):3448–3454

Chellali MR, Balogh Z, Schmitz G (2013) Nano-analysis of grain boundary and triple junction transport in nanocrystalline Ni/Cu. Ultramicroscopy 132:164–170

Stender P, Balogh Z, Schmitz G (2011) Triple junction segregation in nanocrystalline multilayers. Phys Rev B Condens Matter Mater Phys 83(12):1–4

Stender P, Balogh Z, Schmitz G (2011) Triple line diffusion in nanocrystalline Fe/Cr and its impact on thermal stability. Ultramicroscopy 111(6):524–529

Eich SM, Schmitz G (2018) Embedded-atom study of grain boundary segregation and grain boundary free energy in nanosized iron-chromium tricrystals. Acta Mater 147:350–364

Josiah Willard Gibbs (1928) The collected works of J. W. Gibbs: thermodynamics. Longmans, Green, & Co., London, p 463

Krakauer BW, Seidman DN (1993) Absolute atomic-scale measurements of the Gibbsian interfacial excess of solute at internal interfaces. Phys Rev B 48(9):6724–6727

Murarka SP (1995) Silicide thin films and their applications in microelectronics. Intermetallics 3(3):173–186

Lau SS, Mayer JW, Tu KN (1978) Interactions in the Co/Si thin film system. I. Kinetics. J Appl Phys 49(7):4005–4010

D’Heurle FM, Petersson CS (1985) Formation of thin films of CoSi2: nucleation and diffusion mechanisms. Thin Solid Films 128(3–4):283–297

Dass MLA, Fraser DB, Wei C-S (1991) Growth of epitaxial CoSi2 on (100)Si. Appl Phys Lett 58(12):1308–1311

Hsia SL, Tan TY, Smith P, McGuire GE (1991) Formation of epitaxial CoSi2 films on (001) silicon using Ti–Co alloy and bimetal source materials. J Appl Phys 70(12):7579–7587

Liu P, Li B-Z, Sun Z, Zhi-Guang G, Huang W-N, Zhou Z-Y, Ni R-S, Lin C-L, Zou S-C, Hong F, Rozgonyi GA (1993) Epitaxial growth of CoSi2 on both (111) and (100) Si substrates by multistep annealing of a ternary Co/Ti/Si system. J Appl Phys 74(3):1700–1706

Hong F, Rozgonyi GA, Patnaik BK (1994) Mechanisms of epitaxial CoSi2 formation in the multilayer Co/Ti–Si(100) system. Appl Phys Lett 64(17):2241–2243

Selinder TI, Roberts TA, Miller DJ, Beno MA, Knapp GS, Gray KE, Ogawa S, Fair JA, Fraser DB (1995) In situ x-ray diffraction study of CoSi2 formation during annealing of a Co/Ti bilayer on Si(100). J Appl Phys 77(12):6730–6732

Detavernier C, Van Meirhaeghe RL, Cardon F, Maex K, Vandervorst W, Brijs B (2000) Influence of Ti on CoSi2 nucleation. Appl Phys Lett 77(20):3170–3172

Detavernier C, Van Meirhaeghe RL, Cardon F, Donaton RA, Maex K (2000) Influence of Ti capping layers on CoSi2 formation. Microelectron Eng 50:125–132

Detavernier C, Van Meirhaeghe RL, Vandervorst W, Maex K (2004) Influence of processing conditions on CoSi2 formation in the presence of a Ti capping layer. Microelectron Eng 71:252–261

Zschiesche H, Charaï A, Mangelinck D, Alfonso C (2019) Ti segregation at CoSi2 grain boundaries. Microelectron Eng 203–204:1–5

Miller MK, Russell KF, Thompson K, Alvis R, Larson DJ (2007) Review of atom probe FIB-based specimen preparation methods. Microsc Microanal 13:428–436

Felfer PJ, Alam T, Ringer SP, Cairney JM (2012) A reproducible method for damage-free site-specific preparation of atom probe tips from interfaces. Microsc Res Tech 75(4):484–491

Bas P, Bostel A, Deconihout B, Blavette D (1995) A general protocol for the reconstruction of 3D atom probe data. Appl Surf Science 87–88(1–4):298–304

Vurpillot F, Gault B, Geiser BP, Larson DJ (2013) Reconstructing atom probe data: a review. Ultramicroscopy 132:19–30

Warren PJ, Cerezo A, Smith GDW (1998) Observation of atomic planes in 3DAP analysis. Ultramicroscopy 73(1–4):261–266

Jenkins BM, Danoix F, Gouné M, Bagot PAJ, Peng Z, Moody MP, Gault B (2018) Reflections on the analysis of interfaces and grain boundaries by atom probe tomography. arXiv:1806.03851

Sneddon GC, Trimby PW, Cairney JM (2016) Transmission Kikuchi diffraction in a scanning electron microscope: a review. Mater Sci Eng R Rep 110:1–12

Schwarz T, Stechmann G, Gault B, Cojocaru-Mirédin O, Wuerz R, Raabe D (2017) Correlative transmission Kikuchi diffraction and atom probe tomography study of Cu(In, Ga)Se2 grain boundaries. Prog Photovolt Res Appl 26:196–204

Rauch EF, Portillo J, Nicolopoulos S, Bultreys D, Rouvimov S, Moeck P (2010) Automated nanocrystal orientation and phase mapping in the transmission electron microscope on the basis of precession electron diffraction. Z fur Kristallographie 225:103–109

Zaefferer S (2011) A critical review of orientation microscopy in SEM and TEM. Cryst Res Technol 46(6):607–628

Moody MP, Tang F, Gault B, Ringer SP, Cairney JM (2011) Atom probe crystallography: characterization of grain boundary orientation relationships in nanocrystalline aluminium. Ultramicroscopy 111(6):493–499

Breen AJ, Babinsky K, Day AC, Eder K, Oakman CJ, Trimby PW, Primig S, Cairney JM, Ringer SP (2017) Correlating atom probe crystallographic measurements with transmission Kikuchi diffraction data. Microsc Microanal 23(2):279–290

Hellman OC, Vandenbroucke JA, Rüsing J, Isheim D, Seidman DN (2000) Analysis of three-dimensional atom-probe data by the proximity histogram. Microsc Microanal 6(05):437–444

Hellman OC, Seidman DN (2002) Measurement of the Gibbsian interfacial excess of solute at an interface of arbitrary geometry using three-dimensional atom probe microscopy. Mater Sci Eng A 327(1):24–28

Felfer P, Scherrer B, Demeulemeester J, Vandervorst W, Cairney JM (2015) Mapping interfacial excess in atom probe data. Ultramicroscopy 159:438–444

Peng Z, Yifeng L, Hatzoglou C, Silva AKD, Vurpillot F, Ponge D, Raabe D, Gault B (2019) An automated computational approach for complete in-plane compositional interface analysis by atom probe tomography. Microsc Microanal 25(2):389–400

Zhao B, Gottstein G, Shvindlerman LS (2011) Triple junction effects in solids. Acta Mater 59(9):3510–3518

Mattissen D, Molodov DA, Shvindlerman LS, Gottstein G (2005) Drag effect of triple junctions on grain boundary and grain growth kinetics in aluminium. Acta Mater 53(7):2049–2057

Acknowledgements

This work was supported by the French government through the program “Investissements d’Avenir A*MIDEX” (Project APODISE, No. ANR-11-IDEX-0001-02) managed by the National Agency for Research (ANR). The authors would like to thank Maxime Bertoglio for assistance with sample preparation and Marion Descoins for assistance with APT tip preparation and APT measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Geometrical considerations

Appendix: Geometrical considerations

TJ radius (\(r_{\text{TJ}}\)) and GB overlap determination

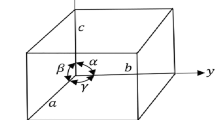

Figure 7 is an visualization of the TJ geometry similar to Fig. 1 with only two GBs that have identical GB width (\(d_{\text{GB,1}}=d_{\text{GB,2}}=d_{\text{GB}}\)) for simplicity. The projected GB1 appears in a green frame, while GB2 is framed in orange. The center of their junction represents the TJ. The frame of the TJ cylinder projection is drawn as a blue circle. The radius of the TJ cylinder (\(r_{\text{TJ}}\)) was defined as the radius of the circle that includes all occurring GB overlap at the TJ. The overlapping area is a tetragon and marked in yellow. The illustration shows that \(r_{\text{TJ}}\) is thereby defined as the diagonal of the overlapping area of the adjacent GBs in the considered case. The angle of the diagonal of the GB overlap area can be calculated to

and with the knowledge of the GB width, the radius of the TJ is

Furthermore, the overlapping area of the adjacent GBs is

GB fraction in TJ

The volume fraction of a single GB in the TJ is related to the area of the GB slice in the TJ cylinder projected along the TJ axis (Fig. 8). It is composed of the horizontally dashed rectangular area \(A_{\text{rect}}\) and the vertically dashed arc area \(A_{\text{arc}}\).

The so calculated projected GB area requires additional correction when all three GBs are considered in the TJ because of GB overlap (Figs. 1, 7): The half of each of the GB overlap rectangles to the adjacent GBs needs to be subtracted

Knowing this projected GB area in the TJ, the volume fraction is calculated by the ratio to the base area of the TJ cylinder

In general, \(d_{\text{GB}}\) is not necessarily the same for all three GBs and \(r_{\text{TJ}}\) depends on both the GB widths and the dihedral angles of the adjacent GBs. The overlapping areas are than more complex and three cases can be distinguished. In the case that the widths of the GBs are different and \(d_{\text{GB},i}>d_{\text{GB,j}}\) and \(d_{\text{GB},i}\le |{d_{\text{GB,j}}/\cos (\gamma )}|\) is fulfilled, the equations for \(S_{\text{ij}}\) and \(r_{\text{TJ}}\) become:

When \(d_{\text{GB},i}<|{d_{\text{GB,j}}/\cos (\gamma )}|\) and \(\gamma >\pi /2\), Eqs. 14 and 15 reduce to

Rights and permissions

About this article

Cite this article

Zschiesche, H., Charai, A., Alfonso, C. et al. Methods for Gibbs triple junction excess determination: Ti segregation in \(\hbox {CoSi}_2\) thin film. J Mater Sci 55, 13177–13192 (2020). https://doi.org/10.1007/s10853-020-04856-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04856-4