Abstract

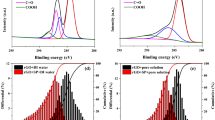

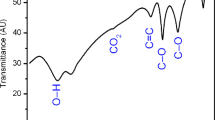

The superior mechanical properties of multi-walled carbon nanotubes (MWCNTs) and prominent dispersibility of graphene oxide (GO) make their hybrid materials have the potential capability for modifying the transport properties of cementitious composites. GO sheets will produce π–π stacking interactions between MWCNTs which not only assist the dispersion but also inhibit the re-agglomeration of the materials. However, as one type of tough two-dimensional materials, GO sheets would cut down the tube length of MWCNTs at the same time, particularly during the ultrasonication process. Thereby, this study characterizes the influence of GO on the dispersion and hydrodynamic size of the hybrid particles using an ultraviolet–visible spectrophotometer and laser particle-size analyzer, respectively. The transport properties of GO/MWCNTs-OPC pastes containing different ratios of hybrid materials were measured, and their microstructure was investigated by mercury intrusion porosimetry and scanning electron microscopy (SEM). The results of this study confirm that 0.02 wt% GO mixed into 0.04 wt% MWCNTs would balance the dispersion-assisted and nanoparticle cutdown effects well and obtain the optimal decrease in resisting water permeability of the materials, about 55.3%, while excessive GO mixing may deteriorate particle-size and influence reinforcing efficiency. Two analytical models and SEM images reveal the mechanism of transport properties reinforcement; GO/MWCNTs not only play a significant role as nucleating sites in assisting the hydration reaction but also form a net-like distribution in the microstructure of cementitious composites. The findings of this study can guide GO/MWCNTs hybrid composite implementation in the future.

Similar content being viewed by others

References

Schmidt T, Lothenbach B, Romer M et al (2009) Physical and microstructural aspects of sulfate attack on ordinary and limestone blended Portland cements. Cem Concr Res 39(12):1111–1121

Pacheco-Torgal F, Castro-Gomes J, Jalali S (2008) Alkali-activated binders: a review: Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr Build Mater 22(7):1305–1314

Patel RA, Phung QT, Seetharam SC et al (2016) Diffusivity of saturated ordinary Portland cement-based materials: a critical review of experimental and analytical modelling approaches. Cem Concr Res 90:52–72

Mahasenan N, Smith S, Humphreys K (2003) The cement industry and global climate change current and potential future cement industry CO2 emissions. In: 6th International conference on greenhouse gas control technologies, pp 995–1000

Khalaj G, Hassani SES, Khezrloo A et al (2014) Split tensile strength of OPC-based geopolymers: application of DOE method in evaluating the effect of production parameters and their optimum condition. Ceram Int 40(7):10945–10952

Pan Z, Sanjayan JG, Rangan BV (2011) Fracture properties of geopolymer paste and concrete. Mag Concr Res 63(10):763–771

Amnadnua K, Tangchirapat W, Jaturapitakkul C (2013) Strength, water permeability, and heat evolution of high strength concrete made from the mixture of calcium carbide residue and fly ash. Mater Des 51:894–901

Varol A, Dalgiç S (2006) Grouting applications in the Istanbul metro. Tunn Undergr Sp Technol 21(6):602–612

Li SC, Liu RT, Zhang QS et al (2016) Protection against water or mud inrush in tunnels by grouting: a review. JRMGE 8:753–766

Liu R, Xiao HG, Li H et al (2018) Effects of nano-SiO2 on the permeability-related properties of cement-based composites with different water/cement ratios. J Mater Sci 53:4974–4986. https://doi.org/10.1007/s10853-017-1906-8

Brandt AM (2008) Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos Struct 86(1–3):3–9

Bhargava A, Banthia N (2008) Permeability of concrete with fiber reinforcement and service life predictions. Mater Struct 41(2):363–372

Collins F, Lambert J, Duan WH (2012) The influences of admixtures on the dispersion, workability, and strength of carbon nanotube-OPC paste mixtures. Cem Concr Compos 34(2):201–207

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Lee H, Kang D, Kim J et al (2019) Void detection of cementitious grout composite using single-walled and multi-walled carbon nanotubes. Cem Concr Compos 95:237–246

Chen SJ, Collins FG, Macleod AJN et al (2011) Carbon nanotube-cement composites: a retrospect. IES J Part A Civ Struct Eng 4:254–265

Yu MF, Lourie O, Dyer MJ et al (2000) Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 287(5453):637–640

Du MR, Jing HW, Duan WH et al (2017) Methylcellulose stabilized multi-walled carbon nanotubes dispersion for sustainable cement composites. Constr Build Mater 146:76–85

Gao Y, Jing HW, Du MR et al (2018) Dispersion of multi-walled carbon nanotubes stabilized by humic acid in sustainable cement composites. Nanomaterials 8:858

Chen SJ, Qiu CY, Korayem AH et al (2016) Agglomeration process of surfactant-dispersed carbon nanotubes in unstable dispersion: a two-stage agglomeration model and experimental evidence. Powder Technol 301:412–420

Zou B, Chen SJ, Korayem AH et al (2015) Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon 85:212–220

Chen SJ, Zou B, Collins F et al (2014) Predicting the influence of ultrasonication energy on the reinforcing efficiency of carbon nanotubes. Carbon 77:1–10

Korayem AH, Barati MR, Chen SJ et al (2015) Optimizing the degree of carbon nanotube dispersion in a solvent for producing reinforced epoxy matrices. Powder Technol 284:541–550

Chen SJ, Wang W, Sagoe-Crentsil K et al (2016) Distribution of carbon nanotubes in fresh ordinary portland cement pastes: understanding from a two-phase perspective. RSC Adv 6:5745–5753

Rajabipour F, Sant G, Weiss J (2008) Interactions between shrinkage reducing admixtures (SRA) and cement paste’s pore solution. Cem Concr Res 38(5):606–615

Gong K, Pan Z, Korayem AH et al (2015) Reinforcing effects of graphene oxide on portland cement paste. J Mater Civil Eng 27(2):A4014010

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6(3):183–191

Gao Y, Jing HW, Zhou ZF (2019) Fractal analysis of pore structure in graphene oxide-carbon nanotube based cementitious pastes under different ultrasonication. Nanotechnol Rev 8(1):107–115

Kudin KN, Ozbas B, Schniepp HC et al (2008) Raman spectra of graphite oxide and functionalized graphene sheets. Nano Lett 8(1):36–41

Zhang C, Ren LL, Wang XY et al (2010) Graphene oxide-assisted dispersion of pristine multiwalled carbon nanotubes in aqueous media. J Phys Chem C 114(26):11435–11440

Zhao DM, Li ZM, Liu LD et al (2014) Progress of preparation and application of graphene/carbon nanotube composite materials. Acta Chim Sin 72(2):185–200

Zhou C, Li FX, Hu J et al (2017) Enhanced mechanical properties of cement paste by hybrid graphene oxide/carbon nanotubes. Constr Build Mater 134:336–345

Gao Y, Jing HW, Zhou ZF et al (2019) Reinforced impermeability of cementitious composites using graphene oxide–carbon nanotube hybrid under different water-to-cement ratios. Constr Build Mater 222:610–621

Gao Y, Jing HW, Chen SJ et al (2019) Influence of ultrasonication on the dispersion and enhancing effect of graphene oxide–carbon nanotube hybrid nanoreinforcement in cementitious composite. Compos Part B-Eng 164:45–53

Li XG, Wei W, Qin H et al (2015) Co-effects of graphene oxide sheets and single wall carbon nanotubes on mechanical properties of cement. J Phys Chem Solids 85:39–43

Roy DM, Jiang WM, Silsbee MR (2000) Chloride diffusion in ordinary, blended, and alkali-activated cement pastes and its relation to other properties. Cem Concr Res 30(12):1879–1884

Ryan PC, O’Connor A (2016) Comparing the durability of self-compacting concretes and conventionally vibrated concretes in chloride rich environments. Constr Build Mater 120:504–513

Powers TC (1958) Structure and physical properties of hardened portland cement paste. J Am Ceram Soc 41(1):1–6

Konsta-Gdoutos MS, Metaxa ZS, Shah SP (2010) Highly dispersed carbon nanotube reinforced cement based materials. Cem Concr Res 40(7):1052–1059

Huang HL, Qian CX, Zhao F et al (2016) Improvement on microstructure of concrete by polycarboxylate superplasticizer (PCE) and its influence on durability of concrete. Constr Build Mater 110:293–299

ICS Standard GB175 (2007) Common Portland cement. Standard Press of China, Beijing

Huang N, Liu RC, Jiang YJ et al (2019) Shear-flow coupling characteristics of a three-dimensional discrete fracture network-fault model considering stress-induced aperture variations. J Hydrol 571:416–424

Twibell B, Somerville K, Manani G et al (2017) Influence of CNTRENE® C100LM carbon nanotube material on the growth and regulation of Escherichia coli. Peer J 5:e3721

Zhu YW, Murali S, Cai WW et al (2010) Graphene and graphene oxide: synthesis, properties, and applications. Adv Mater 22(35):3906–3924

Nardelli MB, Fattebert JL, Orlikowski D et al (2000) Mechanical properties, defects and electronic behavior of carbon nanotubes. Carbon 38(11–12):1703–1711

Clark MD, Jespersen ML, Patel RJ et al (2013) Predicting vertical phase segregation in polymer-fullerene bulk heterojunction solar cells by free energy analysis. ACS Appl Mater Interfaces 5(11):4799–4807

Li ZF, Luo GH, Zhou WP et al (2006) The quantitative characterization of the concentration and dispersion of multi-walled carbon nanotubes in suspension by spectrophotometry. Nanotechnology 17(15):3692–3698

Baskaran D, Mays JW, Bratcher MS (2005) Noncovalent and nonspecific molecular interactions of polymers with multiwalled carbon nanotubes. Chem Mater 17(13):3389–3397

Cui L, Cahyadi JH (2001) Permeability and pore structure of OPC paste. Cem Concr Res 31(2):277–282

Hansen TC (1986) Physical structure of hardened cement paste. A classical approach. Mater Struct 19:423–436

Bentz DP, Garboczi EJ (1991) Percolation of phases in a three-dimensional cement paste microstructural model. Cem Concr Res 21(2–3):325–344

Christensen BJ, Mason TO, Jennings HM (1996) Comparison of measured and calculated permeabilities for hardened cement pastes. Cem Concr Res 26(9):1325–1334

Zhou CS (2014) Predicting water permeability and relative gas permeability of unsaturated cement-based material from hydraulic diffusivity. Cem Concr Res 58:143–151

Mclachlan DS (2000) An equation for the conductivity of binary mixtures with anisotropic grain structures. J Phys C: Solid State Phys 20(7):865–877

Mclachlan DS (1986) A new interpretation of percolation conductivity results with large critical regimes. Solid State Commun 60(10):821–825

Mclachlan DS (2000) Measurement and analysis of a model dual conductivity medium using a generalized effective medium theory. J Phys C: Solid State Phys 21(8):1521

Bentz DP, Garboczi EJ, Martys NS (1996) Application of digital-image-based models to microstructure, transport properties, and degradation of cement-based materials. The modelling of microstructure and its potential for studying transport properties and durability. Springer, Dordrecht, pp 167–185

Li GY, Wang PM, Zhao X (2005) Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 43(6):1239–1245

Makar JM, Chan GW (2010) Growth of cement hydration products on single walled carbon nanotubes. J Am Ceram Soc 92(6):1303–1310

Nochaiya T, Chaipanich A (2011) Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl Surf Sci 257(6):1941–1945

Acknowledgements

This study was supported by the Postgraduate Research and Practice Innovation Program of Jiangsu Province (No. KYCX19_2169), Postgraduate Research and Practice Innovation Program of China University of Mining and Technology and the National Natural Science Foundation of China, China (No. 51734009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, Y., Jing, H., Zhou, Z. et al. Graphene oxide-assisted multi-walled carbon nanotube reinforcement of the transport properties in cementitious composites. J Mater Sci 55, 603–618 (2020). https://doi.org/10.1007/s10853-019-04040-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04040-3