Abstract

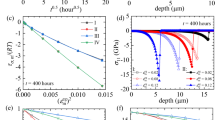

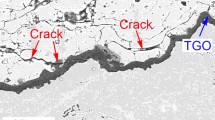

A chemo-transport-mechanics model is developed to study the growth of thermally grown oxide (TGO) and its impact on deformation and stress in air plasma-sprayed thermal barrier coatings (TBCs). As the driving force for oxygen transport, the chemical potential consists of contributions from both species concentration and hydrostatic pressure. The model suggests that both the concentration boundary condition and the transport process of the oxygen are affected by hydrostatic stress. Since oxygen has smaller diffusion coefficient in TGO than in BC, the retarding effect of the formed TGO on oxygen transport is considered and clarified by the coupled model. The competition between geometrical imperfection (i.e. concave morphology) and the chemo-mechanics coupling to influence the transport of oxygen is also identified numerically. The geometrical imperfection can introduce additional oxygen transport at the margin of the concave imperfection due to the horizontal component of the gradient of the chemical potential of the oxygen, which plays a dominant role in the TGO growth kinetics for the studied TBCs. Consequently, there is a limited effect of the chemo-mechanics coupling on the growth kinetics of a concaved TGO. The amplitude change of the concave portion is found to be up to 0.36 µm after 600-h exposure at 1150 °C, which leads to large tensile stress above the concave portion potentially causing micro-cracks.

Similar content being viewed by others

Abbreviations

- σ :

-

Hydrostatic stress

- σ ij :

-

Stress component

- ε ij :

-

Strain component

- K ijkl :

-

Stiffness matrix

- ε e ij :

-

Elastic strain

- ε p ij :

-

Plastic strain

- ε T ij :

-

Thermal strain

- ε g ij :

-

Growth strain

- ε c ij :

-

Chemical strain

- u i :

-

Displacement

- α :

-

Coefficient of thermal expansion (CTE)

- T :

-

Temperature

- T 0 :

-

Reference temperature

- R PB :

-

Pilling–Bedworth ratio

- ξ :

-

Oxide volume percentage

- c :

-

Oxygen concentration

- Ω :

-

Partial molar volume

- μ :

-

Chemical potential

- μ 0 :

-

Reference chemical potential

- R :

-

Gas constant

- J :

-

Diffusion flux

- D :

-

Diffusion coefficient

- D 0 :

-

Reference diffusion coefficient

- H(ξ):

-

Step function

- v :

-

Chemical reaction rate

- K :

-

Chemical reaction constant

- r D :

-

Ratio of diffusion coefficient of oxygen in TGO to that in BC

References

Padture NP, Gell M, Jordan EH (2002) Thermal barrier coatings for gas-turbine engine applications. Science 296:280–284

Evans AG, Mumm DR, Hutchinson JW et al (2001) Mechanisms controlling the durability of thermal barrier coatings. Prog Mater Sci 5:505–553

Clarke DR, Oechsner M, Padture NP (2012) Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull 37:891–898

Xu R, Fan XL, Zhang WX et al (2013) Effects of geometrical and material parameters of top and bond coats on the interfacial fracture in thermal barrier coating system. Mater Des Complete 47:566–574. https://doi.org/10.1016/j.matdes.2012.12.053

Xu R, Fan X, Wang TJ (2016) Mechanisms governing the interfacial delamination of thermal barrier coating system with double ceramic layers. Appl Surf Sci C 370:394–402

Jiang P, Fan X, Sun Y et al (2018) Bending-driven failure mechanism and modelling of double-ceramic-layer thermal barrier coating system. Int J Solids Struct 130–131:11–20

Sun Y, Li J, Zhang W, Wang TJ (2013) Local stress evolution in thermal barrier coating system during isothermal growth of irregular oxide layer. Surf Coat Technol 216:237–250

Sun Y, Zhang W, Li J, Wang TJ (2013) Local stress around cap-like portions of anisotropically and nonuniformly grown oxide layer in thermal barrier coating system. J Mater Sci 48:5962–5982. https://doi.org/10.1007/s10853-013-7393-7

Fan XL, Qin WJ (2011) Stress distribution in the vicinity of thermally grown oxide of thermal barrier coatings. Adv Mater Res 160–162:721–725

Fan XL, Zhang WX, Wang TJ, Sun Q (2012) The effect of thermally grown oxide on multiple surface cracking in air plasma sprayed thermal barrier coating system. Surf Coat Technol 208:7–13

Su L, Zhang W, Sun Y, Wang TJ (2014) Effect of TGO creep on top-coat cracking induced by cyclic displacement instability in a thermal barrier coating system. Surf Coat Technol C 254:410–417

Xu R, Fan XL, Zhang WX, Wang TJ (2014) Interfacial fracture mechanism associated with mixed oxides growth in thermal barrier coating system. Surf Coat Technol 253:139–147

Li B, Fan X, Zhou K, Wang TJ (2017) Effect of oxide growth on the stress development in double-ceramic-layer thermal barrier coatings. Ceram Int 43:14763–14774

Lv J, Fan X, Li Q (2017) The impact of the growth of thermally grown oxide layer on the propagation of surface cracks within thermal barrier coatings. Surf Coat Technol 309:1033–1044

Evans HE (2011) Oxidation failure of TBC systems: an assessment of mechanisms. Surf Coat Technol 206:1512–1521

Busso EP, Wright L, Evans HE et al (2007) A physics-based life prediction methodology for thermal barrier coating systems. Acta Mater 55:1491–1503

Rabiei A, Evans AG (2000) Failure mechanisms associated with the thermally grown oxide in plasma-sprayed thermal barrier coatings. Acta Mater 48:3963–3976

Evans AG, He MY, Hutchinson JW (2001) Mechanics-based scaling laws for the durability of thermal barrier coatings. Prog Mater Sci 46:249–271

Fan XL, Xu R, Zhang WX, Wang TJ (2012) Effect of periodic surface cracks on the interfacial fracture of thermal barrier coating system. Appl Surf Sci 258:9816–9823

Busso EP, Qian ZQ, Taylor MP, Evans HE (2009) The influence of bondcoat and topcoat mechanical properties on stress development in thermal barrier coating systems. Acta Mater 57:2349–2361

Busso EP, Evans HE, Qian ZQ, Taylor MP (2010) Effects of breakaway oxidation on local stresses in thermal barrier coatings. Acta Mater 58:1242–1251

He MY, Hutchinson JW, Evans AG (2002) Large deformation simulations of cyclic displacement instabilities in thermal barrier systems. Acta Mater 50:1063–1073

Karlsson AM, Hutchinson JW, Evans AG (2002) A fundamental model of cyclic instabilities in thermal barrier systems. J Mech Phys Solids 50:1565–1589

Karlsson AM, Xu T, Evans AG (2002) The effect of the thermal barrier coating on the displacement instability in thermal barrier systems. Acta Mater 50:1211–1218

Kang K-J, Hutchinson JW, Evans AG (2003) Measurement of the strains induced upon thermal oxidation of an alumina-forming alloy. Acta Mater 51:1283–1291

He MY, Hutchinson JW, Evans AG (2003) Simulation of stresses and delamination in a plasma-sprayed thermal barrier system upon thermal cycling. Mater Sci Eng A 345:172–178

Karlsson AM, Hutchinson JW, Evans AG (2003) The displacement of the thermally grown oxide in thermal barrier systems upon temperature cycling. Mater Sci Eng A 351:244–257

Xu T, He MY, Evans AG (2003) A numerical assessment of the durability of thermal barrier systems that fail by ratcheting of the thermally grown oxide. Acta Mater 51:3807–3820

Zhou H (2010) Stress-diffusion interaction during oxide scale growth on metallic alloys. Ph.D. Dissertation. Georgia Institute of Technology

Loeffel K, Anand L (2011) A chemo-thermo-mechanically coupled theory for elastic–viscoplastic deformation, diffusion, and volumetric swelling due to a chemical reaction. Int J Plast 27:1409–1431

Loeffel K, Anand L, Gasem ZM (2013) On modeling the oxidation of high-temperature alloys. Acta Mater 61:399–424

Chen L, Yueming L (2018) A coupled mechanical-chemical model for reflecting the influence of stress on oxidation reactions in thermal barrier coating. J Appl Phys 123:215305

Suo Y, Shen S (2015) Coupling diffusion–reaction–mechanics model for oxidation. Acta Mech 226:3375–3386

Wang T, Fan XL et al (2016) The stresses and cracks in thermal barrier coating system: a review. Chin J Solid Mech 37(6):477–517

Mura T (1987) Micromechanics of defects in solids, 2nd edn. Springer, Dordrecht

Panicaud B, Grosseau-Poussard JL, Dinhut JF (2008) General approach on the growth strain versus viscoplastic relaxation during oxidation of metals. Comput Mater Sci 42:286–294

Suo Y, Shen S (2013) General approach on chemistry and stress coupling effects during oxidation. J Appl Phys 114:164905

Suo Y, Yang X, Shen S (2015) Residual stress analysis due to chemomechanical coupled effect, intrinsic strain and creep deformation during oxidation. Oxid Met 84:413–427

Panicaud B, Grosseau-Poussard JL, Dinhut JF (2006) On the growth strain origin and stress evolution prediction during oxidation of metals. Appl Surf Sci 252:5700–5713

Maharjan S, Zhang XC, Xuan FZ et al (2011) Residual stresses within oxide layers due to lateral growth strain and creep strain: analytical modeling. J Appl Phys 110:063511

Tolpygo VK, Dryden JR, Clarke DR (1998) Determination of the growth stress and strain in α-Al2O3 scales during the oxidation of Fe–22Cr–4.8Al–0.3Y alloy. Acta Mater 46:927–937

Ruan JL, Pei Y, Fang D (2012) Residual stress analysis in the oxide scale/metal substrate system due to oxidation growth strain and creep deformation. Acta Mech 223:2597–2607

Ruan JL, Pei Y, Fang D (2013) On the elastic and creep stress analysis modeling in the oxide scale/metal substrate system due to oxidation growth strain. Corros Sci 66:315–323

Hsueh CH, Evans AG (1983) Oxidation induced stresses and some effects on the behavior of oxide films. J Appl Phys 54:6672–6686. https://doi.org/10.1063/1.331854

Pilling N, Bedworth RJ (1923) The oxidation of metals at high temperatures. J Inst Met 29:529–582

Li JCM (1981) Chemical potential for diffusion in a stressed solid. Scr Metall 15:21–28

Reynolds O (1903) Papers on mechanical and physical subjects, vol 3. Cambridge University Press, Cambridge

Devereux OF (1983) Topics in metallurgical thermodynamics: solutions manual. Wiley-Interscience, New York

Shillington EAG, Clarke DR (1999) Spalling failure of a thermal barrier coating associated with aluminum depletion in the bond-coat. Acta Mater 47(4):1297–1305

Wang L, Yang JS, Ni JX et al (2016) Influence of cracks in APS-TBCs on stress around TGO during thermal cycling: a numerical simulation study. Surf Coat Technol 285:98–112

Quested PN, Brooks RF, Chapman L et al (2009) Measurement and estimation of thermophysical properties of Nickel based superalloys. Mater Sci Technol 25:154–162

Jiang W, Zhang Y-C, Zhang WY et al (2016) Growth and residual stresses in the bonded compliant seal of planar solid oxide fuel cell: Thickness design of window frame. Mater Des C 93:53–62

Cheng J, Jordan EH, Barber B, Gell M (1998) Thermal/residual stress in an electron beam physical vapor deposited thermal barrier coating system. Acta Mater 46:5839–5850

Martena M, Botto D, Fino P et al (2006) Modelling of TBC system failure: stress distribution as a function of TGO thickness and thermal expansion mismatch. Eng Fail Anal 13:409–426

Richards BT, Young KA, de Francqueville F et al (2016) Response of ytterbium disilicate–silicon environmental barrier coatings to thermal cycling in water vapor. Acta Mater 106:1–14

Knipe K, Manero Ii A, Siddiqui SF et al (2014) Strain response of thermal barrier coatings captured under extreme engine environments through synchrotron X-ray diffraction. Nat Commun 5:4559

Acknowledgements

This work is supported by NSFC (11472204 and 1171101165) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Fan, X., Sun, Y. et al. Modelling and analysis of the oxide growth coupling behaviour of thermal barrier coatings. J Mater Sci 54, 10270–10283 (2019). https://doi.org/10.1007/s10853-019-03620-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03620-7