Abstract

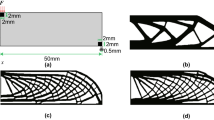

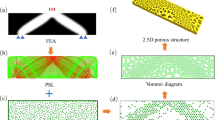

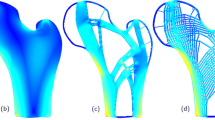

In this work, we present four types of topological bicontinuous porous structures, namely Gyroid (G), Schwarz Diamond (D), Schwarz Primitive (P), and iWp (W), which are generated from mathematically defined triply periodic minimal surfaces. A systematic semi-theoretical investigation is performed to analyze the relations between the microstructures and the macroscopic mechanical behavior. Benefiting from the straightforward controllability on parameters, the scaling laws of the geometrical properties and mechanical properties are determined as functions of the relative density according to numerical analysis and computational simulation. An application to additive manufacturing accompanying with uniaxial compression testing is also performed, and the results show a highly agreement with the above scaling laws. Moreover, the simulation results indicate that the mechanical properties are highly dependent on topological architectures, which affect the deformation behavior of porous materials. It is shown that P topology has the highest stiffness and strength with stretching-dominated mode, while the rest exhibit a flexibly bending-dominated deformation behavior. The present study provides not only new insights into the structure–property relations of such topologies, but also a practical guide for their fabrication and application.

Similar content being viewed by others

References

Giannitelli S, Accoto D, Trombetta M, Rainer A (2014) Current trends in the design of scaffolds for computer-aided tissue engineering. Acta Biomater 10(2):580

Kantaros A, Chatzidai N, Karalekas D (2016) 3D printing-assisted design of scaffold structures. Int J Adv Manuf Technol 82(1–4):559

Wang X, Xu S, Zhou S, Xu W, Leary M, Choong P, Qian M, Brandt M, Xie YM (2016) Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review. Biomaterials 83:127

Choren JA, Heinrich SM, Silver-Thorn MB (2013) Young’s modulus and volume porosity relationships for additive manufacturing applications. J Mater Sci 48(15):5103. https://doi.org/10.1007/s10853-013-7237-5

Shbeh MM, Goodall R (2017) Open celled porous titanium. Adv Eng Mater 19(11):1600664

Gu D, Meiners W, Wissenbach K, Poprawe R (2012) Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int Mater Rev 57(3):133

Olhero SM, Fernandes HR, Marques CF, Silva BC, Ferreira JM (2017) Additive manufacturing of 3D porous alkali-free bioactive glass scaffolds for healthcare applications. J Mater Sci 52(20):12079. https://doi.org/10.1007/s10853-017-1347-4

Lurie S, Solyaev Y, Rabinskiy L, Polyakov P, Sevostianov I (2018) Mechanical behavior of porous Si3N4 ceramics manufactured with 3D printing technology. J Mater Sci 53(7):4796. https://doi.org/10.1007/s10853-017-1881-0

Compton BG, Lewis JA (2014) 3D-printing of lightweight cellular composites. Adv Mater 26(34):5930

Schaedler TA, Jacobsen AJ, Torrents A, Sorensen AE, Lian J, Greer JR, Valdevit L, Carter WB (2011) Ultralight metallic microlattices. Science 334(6058):962

Maiti A, Small W, Lewicki J, Weisgraber T, Duoss E, Chinn S, Pearson M, Spadaccini C, Maxwell R, Wilson T (2016) 3D printed cellular solid outperforms traditional stochastic foam in long-term mechanical response. Sci Rep 6:24871

Papazetis G, Vosniakos GC (2016) Direct porous structure generation of tissue engineering scaffolds for layer-based additive manufacturing. Int J Adv Manuf Technol 86(1–4):871

e Sá AM, Mello VM, Echavarria KR, Covill D (2015) Adaptive voids. Vis Comput 31(6):799

Hedayati R, Sadighi M, Mohammadi-Aghdam M, Zadpoor A (2017) Analytical relationships for the mechanical properties of additively manufactured porous biomaterials based on octahedral unit cells. Appl Math Model 46:408

Hedayati R, Sadighi M, Mohammadi-Aghdam M, Zadpoor A (2016) Mechanical behavior of additively manufactured porous biomaterials made from truncated cuboctahedron unit cells. Int J Mech Sci 106:19

Dementjev A, Tarakanov O (1970) Influence of the cellular structure of foams on their mechanical properties. Mech Polym 4:594

Hedayati R, Sadighi M, Mohammadi-Aghdam M, Zadpoor A (2016) Mechanics of additively manufactured porous biomaterials based on the rhombicuboctahedron unit cell. J Mech Behav Biomed Mater 53:272

Babaee S, Jahromi BH, Ajdari A, Nayeb-Hashemi H, Vaziri A (2012) Mechanical properties of open-cell rhombic dodecahedron cellular structures. Acta Mater 60(6–7):2873

Lord EA, Mackay AL (2003) Periodic minimal surfaces of cubic symmetry. Curr Sci 85(3):346–362

Wohlgemuth M, Yufa N, Hoffman J, Thomas EL (2001) Triply periodic bicontinuous cubic microdomain morphologies by symmetries. Macromolecules 34(17):6083

Mille C, Tyrode EC, Corkery RW (2011) Inorganic chiral 3-D photonic crystals with bicontinuous gyroid structure replicated from butterfly wing scales. Chem Commun 47(35):9873

Gan Z, Turner MD, Gu M (2016) Biomimetic gyroid nanostructures exceeding their natural origins. Sci Adv 2(5):e1600084

Michielsen K, Stavenga DG (2008) Gyroid cuticular structures in butterfly wing scales: biological photonic crystals. J R Soc Interface 5(18):85

Kapfer SC, Hyde ST, Mecke K, Arns CH, Schröder-Turk GE (2011) Minimal surface scaffold designs for tissue engineering. Biomaterials 32(29):6875

Abueidda DW, Bakir M, Al-Rub RKA, Bergström JS, Sobh NA, Jasiuk I (2017) Mechanical properties of 3D printed polymeric cellular materials with triply periodic minimal surface architectures. Mater Des 122:255

Al-Ketan O, Rowshan R, Al-Rub RKA (2018) Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit Manuf 19:167

Abueidda DW, Al-Rub RKA, Dalaq AS, Lee DW, Khan KA, Jasiuk I (2016) Effective conductivities and elastic moduli of novel foams with triply periodic minimal surfaces. Mech Mater 95:102

Abueidda DW, Al-Rub RKA, Dalaq AS, Younes HA, Al Ghaferi AA, Shah TK (2015) Electrical conductivity of 3D periodic architectured interpenetrating phase composites with carbon nanostructured-epoxy reinforcements. Compos Sci Technol 118:127

Abueidda DW, Dalaq AS, Al-Rub RKA, Jasiuk I (2015) Micromechanical finite element predictions of a reduced coefficient of thermal expansion for 3D periodic architectured interpenetrating phase composites. Compos Struct 133:85

Lee DW, Khan KA, Al-Rub RKA (2017) Stiffness and yield strength of architectured foams based on the Schwarz primitive triply periodic minimal surface. Int J Plast 95:1

Dalaq AS, Abueidda DW, Al-Rub RKA, Jasiuk IM (2016) Finite element prediction of effective elastic properties of interpenetrating phase composites with architectured 3D sheet reinforcements. Int J Solids Struct 83:169

Khaderi S, Deshpande V, Fleck N (2014) The stiffness and strength of the gyroid lattice. Int J Solids Struct 51(23–24):3866

Eymard R, Gallouët T, Herbin R (2000) Finite volume methods. Handb Numer Anal 7:713

Kabel M, Andrä H (2012) Fast numerical computation of precise bounds of effective elastic moduli. Berichte des Fraunhofer ITWM 224(224):1

Rutka V, Wiegmann A (2006) Explicit jump immersed interface method for virtual material design of the effective elastic moduli of composite materials. Numer Algorithms 43(4):309

Yi Y, Zheng X, Fu Z, Wang C, Xu X, Tan X (2018) Multi-scale modeling for predicting the stiffness and strength of hollow-structured metal foams with structural hierarchy. Materials 11(3):380

Von Schnering H, Nesper R (1991) Nodal surfaces of Fourier series: fundamental invariants of structured matter. Zeitschrift für Physik B Condens Matter 83(3):407

http://www.msri.org/ (2018). Accessed 1 Jan 2018

Onck P, Andrews E, Gibson L (2001) Size effects in ductile cellular solids. Part I: modeling. Int J Mech Sci 43(3):681

Andrews E, Gioux G, Onck P, Gibson L (2001) Size effects in ductile cellular solids. Part II: experimental results. Int J Mech Sci 43(3):701

https://www.geodict.com/ (2018). Accessed 1 Jan 2018

https://www.formlabs.com/ (2018). Accessed 1 Jan 2018

ASTM International (2015) Standard test method for compressive properties of rigid plastics. ASTM International, West Conshohocken

Danesh G, Lippold C, Ziebura T, Reinhardt KJ, Schäfer E, Ehmer U (2006) In-vitro Investigation on suitability of light-cured resins for interocclusal splints. J Orofac Orthop/Fortschritte der Kieferorthopädie 67(2):138

Gibson LJ, Ashby MF (1999) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Rouquerol J, Avnir D, Fairbridge C, Everett D, Haynes J, Pernicone N, Ramsay J, Sing K, Unger K (1994) Recommendations for the characterization of porous solids (technical report). Pure Appl Chem 66(8):1739

S.S.S. of America (2008) Glossary of soil science terms 2008. ASA-CSSA-SSSA, Madison

Deshpande VS, Fleck NA, Ashby MF (2001) Effective properties of the octet-truss lattice material. J Mech Phys Solids 49(8):1747

Ashby M (2006) The properties of foams and lattices. Philos Trans R Soc Lond A Math Phys Eng Sci 364(1838):15

Deshpande V, Ashby M, Fleck N (2001) Foam topology: bending versus stretching dominated architectures. Acta Mater 49(6):1035

Uchic MD, Dimiduk DM, Florando JN, Nix WD (2004) Sample dimensions influence strength and crystal plasticity. Science 305(5686):986

Hedayati R, Sadighi M, Mohammadi-Aghdam M, Hosseini-Toudeshky H (2018) Comparison of elastic properties of open-cell metallic biomaterials with different unit cell types. J Biomed Mater Res Part B Appl Biomater 106(1):386

Kadkhodapour J, Montazerian H, Raeisi S (2014) Investigating internal architecture effect in plastic deformation and failure for TPMS-based scaffolds using simulation methods and experimental procedure. Mater Sci Eng C 43:587

Acknowledgements

This work was supported by Longshan academic talent research supporting program of SWUST (17LZX408). The authors gratefully acknowledge Dr. Li Bo and Mr. Zhong Shengyuan for equipment and technique support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zheng, X., Fu, Z., Du, K. et al. Minimal surface designs for porous materials: from microstructures to mechanical properties. J Mater Sci 53, 10194–10208 (2018). https://doi.org/10.1007/s10853-018-2285-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2285-5