Abstract

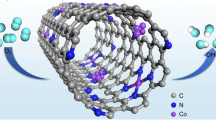

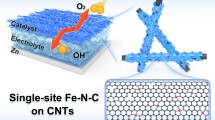

Developing an efficient and low-cost oxygen reduction reaction (ORR) catalyst is the key to realize the commercialization of metal–air batteries. Fe/N-co-doped carbon materials (Fe–N–C) are regarded as one of the most promising oxygen reduction reaction (ORR) catalysts to replace expensive and unstable Pt/C in metal–air batteries. In this work, a new kind of Fe/N-co-doped special carbon nanotube/nanoparticle hybrid catalyst was obtained by using cheap precursors, i.e., ketjenblack EC-600JD (KB), melamine and iron nitrate via a facile high-temperature pyrolysis treatment. The catalyst shows a comparative oxygen reduction reaction (ORR) catalytic activity and better stability than commercial 20 wt% Pt/C in the same test conditions. The outstanding performance results from the doping of Fe and N, which could effectively increase the active sites. Furthermore, a special bamboo-like carbon nanotube is generated due to the catalysis of Fe source. The catalyst exhibits good performance in Al–air batteries. The maximum power density can reach to 300 mW cm−2 with the cell voltage of about 1 V and the current density of 300 mA cm−2.

Similar content being viewed by others

References

Liu QC, Chang ZW, Li ZJ, Zhang XB (2018) Flexible metal–air batteries: progress, challenges, and perspectives. Small Methods 2:1700231

Yuan S, Zhu YH, Li W, Wang S, Xu D, Li L, Zhang Y, Zhang XB (2017) Surfactant-free aqueous synthesis of pure single crystalline SnSe nanosheet clusters as anode for high energy- and power-density sodium-ion batteries. Adv Mater 29:1602469

Wang S, Sun T, Yuan S, Zhu YH, Zhang XB, Yan JM, Jiang Q (2017) P3-type K0.33Co0.53Mn0.47O20.39H2O: a novel bifunctional electrode for Na-ion batteries. Mater Horiz 4:1122–1127

Xu JJ, Chang ZW, Yin YB, Zhang XB (2017) Nanoengineered ultralight and robust all-metal cathode for high capacity, stable lithium-oxygen batteries. ACS Cent Sci 3:598–604

Ma JL, Bao D, Shi MM, Yan JM, Zhang XB (2017) Reversible nitrogen fixation based on a rechargeable lithium-nitrogen battery for energy storage. Chem 2:525–532

Cheng F, Chen J (2012) Metal–air batteries: from oxygen reduction electrochemistry to cathode catalysts. Chem Soc Rev 41:2172–2192

Liu J, Sun X, Song P, Zhang Y, Xing W, Xu W (2013) High-performance oxygen reduction electrocatalysts based on cheap carbon black, nitrogen, and trace iron. Adv Mater 25:6879–6883

Zhang G, Lou XW (2013) General solution growth of mesoporous NiCo2O4 nanosheets on various conductive substrates as high-performance electrodes for supercapacitors. Adv Mater 25:976–979

Sa YJ, Seo DJ, Woo J, Lim JT, Cheon JY, Yang SY, Lee JM, Kang D, Shin TJ, Shin HS, Jeong HY, Kim CS, Kim MG, Kim TY, Joo SH (2016) A general approach to preferential formation of active Fe–Nx sites in Fe–N/C electrocatalysts for efficient oxygen reduction reaction. J Am Chem Soc 138:15046–15056

Debe MK (2012) Electrocatalyst approaches and challenges for automotive fuel cells. Nature 486:43–51

Wang ZL, Xu D, Xu JJ, Zhang XB (2014) Oxygen electrocatalysts in metal–air batteries: from aqueous to nonaqueous electrolytes. Chem Soc Rev 43:7746–7786

Cao R, Lee J, Liu M, Cho J (2012) Non-precious catalysts: recent progress in non-precious catalysts for metal–air batteries. Adv Energy Mater 2:816–829

Ding W, Li L, Xiong K, Wang Y, Li W, Nie Y, Chen S, Qi X, Wei Z (2015) Shape fixing via salt recrystallization: a morphology-controlled approach to convert nanostructured polymer to carbon nanomaterial as a highly active catalyst for oxygen reduction reaction. J Am Chem Soc 137:5414–5420

Jiang WJ, Gu L, Li L, Zhang Y, Zhang X, Zhang LJ, Wang JQ, Hu JS, Wei Z, Wan LJ (2016) Understanding the high activity of Fe–N–C electrocatalysts in oxygen reduction: Fe/Fe3C nanoparticles boost the activity of Fe–Nx. J Am Chem Soc 138:3570–3578

Steele BCH, Heinzel A (2001) Materials for fuel-cell technologies. Nature 414:345–352

Wang Z, Cao X, Ping J, Wang Y, Lin T, Huang X, Ma Q, Wang F, He C, Zhang H (2015) Electrochemical doping of three-dimensional graphene networks used as efficient electrocatalysts for oxygen reduction reaction. Nanoscale 7:9394–9398

Wu G, Zelenay P (2013) Nanostructured nonprecious metal catalysts for oxygen reduction reaction. Acc Chem Res 46:1878–1889

Wang MQ, Yang WH, Wang HH, Chen C, Zhou ZY, Sun SG (2014) Pyrolyzed Fe–N–C composite as an efficient non-precious metal catalyst for oxygen reduction reaction in acidic medium. ACS Catal 4:3928–3936

Jiang Y, Lu Y, Lv X, Han D, Zhang Q, Niu L, Chen W (2013) Enhanced catalytic performance of Pt-free iron phthalocyanine by graphene support for efficient oxygen reduction reaction. ACS Catal 3:1263–1271

Niu W, Li L, Liu X, Wang N, Liu J, Zhou W, Tang Z, Chen S (2015) Mesoporous N-doped carbons prepared with thermally removable nanoparticle templates: an efficient electrocatalyst for oxygen reduction reaction. J Am Chem Soc 137:5555–5562

Wang Q, Zhou ZY, Lai YJ, You Y, Liu JG, Wu XL, Terefe E, Chen C, Song L, Rauf M, Tian N, Sun SG (2014) Phenylenediamine-based FeNx/C catalyst with high activity for oxygen reduction in acid medium and its active-site probing. J Am Chem Soc 136:10882–10885

Lin L, Zhu Q, Xu AW (2014) Noble-metal-free Fe–N/C catalyst for highly efficient oxygen reduction reaction under both alkaline and acidic conditions. J Am Chem Soc 136:11027–11033

Maldonado S, Stevenson KJ (2005) Influence of nitrogen doping on oxygen reduction electrocatalysis at carbon nanofiber electrodes. J Phys Chem B 109:4707–4716

Li W, Wu J, Higgins DC, Choi JY, Chen Z (2015) Determination of iron active sites in pyrolyzed iron-based catalysts for the oxygen reduction reaction. ACS Catal 2:2761–2768

Chung HT, Won JH, Zelenay P (2013) Active and stable carbon nanotube/nanoparticle composite electrocatalyst for oxygen reduction. Nat Commun 4:1922–1926

Li Q, Pan H, Higgins D, Cao R, Zhang G, Lv H, Wu K, Cho J, Wu G (2015) Metal-organic framework-derived bamboo-like nitrogen-doped graphene tubes as an active matrix for hybrid oxygen-reduction electrocatalysts. Small 11:1443–1452

Wen Z, Ci S, Zhang F, Feng X, Cui S, Mao S, Luo S, He Z, Chen J (2012) Nitrogen-enriched core-shell structured Fe/Fe(3)C-C nanorods as advanced electrocatalysts for oxygen reduction reaction. Adv Mater 24:1399–1404

Qu D (2007) Investigation of oxygen reduction on activated carbon electrodes in alkaline solution. Carbon 45:1296–1301

Wong WY, Daud WRW, Mohamad AB, Kadhum AAH, Loh KS, Majlan EH (2013) Influence of nitrogen doping on carbon nanotubes towards the structure, composition and oxygen reduction reaction. Int J Hydrogen Energy 38:9421–9430

Yang Z, Nie H, Chen X, Chen X, Huang S (2013) Recent progress in doped carbon nanomaterials as effective cathode catalysts for fuel cell oxygen reduction reaction. J Power Sources 236:238–249

Liang J, Zhou RF, Chen XM, Tang YH, Qiao SZ (2014) Fe–N decorated hybrids of CNTs grown on hierarchically porous carbon for high-performance oxygen reduction. Adv Mater 26:6074–6079

Liu S, Zhang H, Zhao Q, Zhang X, Liu R, Ge X, Wang G, Zhao H, Cai W (2016) Metal-organic framework derived nitrogen-doped porous carbon@graphene sandwich-like structured composites as bifunctional electrocatalysts for oxygen reduction and evolution reactions. Carbon 106:74–83

Liu C, Wang J, Li J, Luo R, Sun X, Shen J, Han W, Wang L (2017) Fe/N decorated mulberry-like hollow mesoporous carbon fibers as efficient electrocatalysts for oxygen reduction reaction. Carbon 114:706–716

Qian Y, Du P, Wu P, Cai C, Gervasio DF (2016) Chemical nature of catalytic active sites for the oxygen reduction reaction on nitrogen-doped carbon-supported non-noble metal catalysts. J Phys Chem C 120:9884–9896

Li F, Fu L, Li J, Feng Q, Wang HY, Tang YG (2017) Fe7C3–Fe3N/FeNxCy decorated carbon materials as highly efficient catalyst for oxygen reduction reaction in Al–air batteries. Nanosci Nanotechnol Lett 9:1909–1918

Li J, Zhou N, Song J, Fu L, Yan J, Tang YG, Wang HY (2018) Cu-MOF-derived Cu/Cu2O nanoparticles and CuNxCy species to boost oxygen reduction activity of ketjenblack carbon in Al–air battery. ACS Sustain Chem Eng 6:413–421

Li F, Fu L, Li J, Yan J, Tang YG, Pan Y, Wang HY (2017) Ag/Fe3O4-N-doped ketjenblack carbon composite as highly efficient oxygen reduction catalyst in Al–air batteries. J Electrochem Soc 164:3595–3601

Liu K, Zhou Z, Wang HY, Huang X, Xu J, Tang YG, Li J, Chu H, Chen J (2016) N-doped carbon supported Co3O4 nanoparticles as an advanced electrocatalyst for oxygen reduction reaction in Al–air battery. RSC Adv 6:55552–55559

Li J, Chen J, Wang HY, Ren Y, Liu K, Tang YG, Shao M (2017) Fe/N co-doped carbon materials with controllable structure as highly efficient electrocatalysts for oxygen reduction reaction in Al–air batteries. Energy Storage Mater 8:49–58

Liu R, Wu D, Feng X, Mllen K (2010) Nitrogen-doped ordered mesoporous graphitic arrays with high electrocatalytic activity for oxygen reduction. Angew Chem 122:2619–2623

Song P, Zhang Y, Pan J, Zhuang L, Xu W (2015) Cheap carbon black-based high-performance electrocatalysts for pxygen reduction reaction. Chem Commun 51:1972–1975

Yang W, Fellinger TP, Antonietti M (2011) Efficient metal-free oxygen reduction in alkaline medium on high-surface-area mesoporous nitrogen-doped carbons made from ionic liquids and nucleobases. J Am Chem Soc 133:206–209

Liu S, Dong Y, Wang Z, Huang H, Zhao Z, Qiu J (2015) Towards efficient electrocatalysts for oxygen reduction by doping cobalt into graphene-supported graphitic carbon nitride. J Mater Chem A 3:19657–19661

Huang X, Yang Z, Dong B, Wang Y, Tang T, Hou Y (2017) In situ Fe2N@N-doped porous carbon hybrids as superior catalysts for oxygen reduction reaction. Nanoscale 9:8102–8106

Osmieri L, Ricardo EC, Videlaa AHAM, Ocónb P, Specchiaa S (2017) Performance of a Fe–N–C catalyst for the oxygen reduction reaction in direct methanol fuel cell: cathode formulation optimization and short-term durability. Appl Catal B 201:253–265

Yang M, Chen H, Yang D, Gao Y, Li H (2016) Using nitrogen-rich polymeric network and iron(II) acetate as precursors to synthesize highly efficient electrocatalyst for oxygen reduction reaction in alkaline media. J Power Sources 307:152–159

Acknowledgements

This research was financially supported by the National Nature Science Foundation of China (Nos. 21571189, 21671200 and 21771062), the Hunan Provincial Science and Technology Plan Project (Nos. 2016TP1007 and 2017TP1001), the Opening Project of Material Corrosion and Protection Key Laboratory of Sichuan Province of China (Nos. 2016CL04 and 2017CL17), the Innovation-Driven Project of Central South University (No. 2016CXS009) and the Talents Project of Si Chuan University of Science and Engineering (No. 2014RC30).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, L., Fu, L., Li, J. et al. On an easy way to prepare highly efficient Fe/N-co-doped carbon nanotube/nanoparticle composite for oxygen reduction reaction in Al–air batteries. J Mater Sci 53, 10280–10291 (2018). https://doi.org/10.1007/s10853-018-2245-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2245-0