Abstract

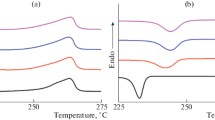

In this study, the morphological, thermal and electrical properties of microinjection-molded multi-walled carbon nanotubes (CNT)-filled poly(lactic acid) (PLA) and PLA/poly[(butylene succinate)-co-adipate] (PLA/PBSA) immiscible blends were studied systematically. The PLA/PBSA/CNT immiscible blends were prepared by melt blending of PLA, PBSA and CNT in a batch mixer. Four different types of compounding procedure were employed to investigate the influence of compounding sequence of various components on the electrical conductivity of subsequent micromoldings. Results revealed that despite the compounding sequence, the electrical conductivity of PLA/PBSA/CNT microparts is invariably higher than that of CNT-filled mono-PLA counterparts and the selective localization of CNT in PBSA is thought to be the contributing factor. Furthermore, the prevailing high shearing conditions in microinjection molding (µIM) could lead to the coalescence of CNT-enriched PBSA domains, favoring the formation of conductive pathways in the melt flow direction, as confirmed by morphology observations. The crystallinity of PLA/PBSA immiscible blends is higher than that of mono-PLA system and a further increase in crystallinity after µIM suggested flow-induced crystallization. Moreover, thermal stability analysis indicated that the prevailing high shear rates in µIM might have a chain scission effect on PLA and PBSA.

Similar content being viewed by others

References

Giboz J, Copponnex T, Mélé P (2007) Microinjection molding of thermoplastic polymers: a review. J Micromech Microeng 17:96–109

Grabalosa J, Ferrer I, Martínez-Romero O, Elías-Zúñiga A, Plantá X, Rivillas F (2016) Assessing a stepped sonotrode in ultrasonic molding technology. J Mater Process Tech 229:687–696

Abbasi S, Derdouri A, Carreau PJ (2011) Properties of microinjection molding of polymer multiwalled carbon nanotube conducting composites. Polym Eng Sci 51:992–1003

Nair KJ (2014) Micro-injection moulded microneedles for drug delivery. Ph.D. Dissertation, University of Bradford

Whiteside BR, Martyn MT, Coates PD, Greenway G, Allen P, Hornsby P (2004) Micromoulding: process measurements, product morphology and properties. Plast Rubber Compos 33:11–17

Zhang N, Su Q, Choi SY, Gilchrist MD (2015) Effects of gate design and cavity thickness on filling, morphology and mechanical properties of microinjection mouldings. Mater Des 83:835–847

Zhou S, Hrymak AN, Kamal MR (2017) Microinjection molding of polypropylene/multi-walled carbon nanotube nanocomposites: the influence of process parameters. Polym Eng Sci. https://doi.org/10.1002/pen.24682

Zhang N, Choi SY, Gilchrist MD (2014) Flow induced crystallization of poly(ether-block-amide) from the microinjection molding process and its effect on mechanical properties. Macromol Mater Eng 299:1362–1383

Abbasi S, Carreau PJ, Derdouri A (2010) Flow induced orientation of multiwalled carbon nanotubes in polycarbonate nanocomposites: rheology, conductivity and mechanical properties. Polymer 51:922–935

Xiu H, Zhou Y, Huang C, Bai H, Zhang Q, Fu Q (2016) Deep insight into the key role of carbon black self-networking in the formation of co-continuous-like morphology in polylactide/poly(ether)urethane blends. Polymer 82:11–21

Nofar M, Heuzey MC, Carreau PJ, Kamal MR, Randall J (2016) Coalescence in PLA-PBAT blends under shear flow: effects of blend preparation and PLA molecular weight. J Rheol 60:637–648

Mirzadeh A, Ghasemi H, Mahrous F, Kamal MR (2015) Reactive extrusion effects on rheological and mechanical properties of poly(lactic acid)/poly[(butylene succinate)-co-adipate]/epoxy chain extender blends and clay nanocomposites. J Appl Polym Sci 132:42664

Zhou S, Chen Y, Zou H, Liang M (2013) Thermally conductive composites obtained by flake graphite filling immiscible polyamide 6/polycarbonate blends. Thermochim Acta 566:84–91

Zhou S, Luo W, Zou H, Liang M, Li S (2016) Enhanced thermal conductivity of polyamide 6/polypropylene (PA6/PP) immiscible blends with high loadings of graphite. J Compos Mater 50:327–337

Sumita M, Sakata K, Hayakawa Y, Asai S, Miyasaka K, Tanemura M (1992) Double percolation effect on the electrical conductivity of conductive particles filled polymer blends. Colloid Polym Sci 270:134–139

Gubbels F, Blacher S, Vanlathem E, Jérôme R, Deltour R, Brouers F, Teyssié P (1995) Design of electrical conductive composites: key role of the morphology on the electrical properties of carbon black filled polymer blends. Macromolecules 28:1559–1566

Pötschke P, Bhattacharyya AR, Janke A (2004) Carbon nanotube-filled polycarbonate composites produced by melt mixing and their use in blends with polyethylene. Carbon 42:965–969

Xiu H, Huang C, Bai H et al (2014) Improving impact toughness of polylactide/poly(ether)urethane blends via designing the phase morphology assisted by hydrophilic silica nanoparticles. Polymer 55:1593–1600

Xiu H, Zhou Y, Dai J, Huang C, Bai H, Zhang Q, Fu Q (2014) Formation of new electric double percolation via carbon black induced co-continuous like morphology. RSC Adv 4:37193–37196

Dil EJ, Carreau PJ, Favis BD (2015) Morphology, miscibility and continuity development in poly(lactic acid)/poly (butylene adipate-co-terephthalate) blends. Polymer 68:202–212

Tchoudakov R, Breuer O, Narkis M, Siegmann A (1996) Conductive polymer blends with low carbon black loading: polypropylene/polyamide. Polym Eng Sci 36:1336–1346

Foulger SH (1999) Reduced percolation thresholds of immiscible conductive blends. J Polym Sci Polym Phys 37:1899–1910

Al-Saleh MH, Sundararaj U (2009) A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon 47:2–22

Meincke O, Kaempfer D, Weickmann H, Friedrich C, Vathauer M, Warth H (2004) Mechanical properties and electrical conductivity of carbon-nanotube filled polyamide-6 and its blends with acrylonitrile/butadiene/styrene. Polymer 45:739–748

Fang ZP, Ma GW, Shentu BQ, Cai GP, Xu CW (2000) Influence of viscosity ratio on the morphology of PVC/PE blends. Eur Polym J 36:2309–2311

Zhang C, Han HF, Yi XS, Asai S, Sumita M (1998) Selective location of the filler and double percolation of Ketjenblack filled high density polyethylene/isotactic polypropylene blends. Compos Interface 6:227–236

Nofar M, Maani A, Sojoudi H, Heuzey MC, Carreau PJ (2015) Interfacial and rheological properties of PLA/PBAT and PLA/PBSA blends and their morphological stability under shear flow. J Rheol 59:317–333

Nofar M, Heuzey MC, Carreau PJ, Kamal MR (2016) Effects of nanoclay and its localization on the morphology stabilization of PLA/PBAT blends under shear flow. Polymer 98:353–364

Ding W, Chen Y, Liu Z, Yang S (2015) In situ nano-fibrillation of microinjection molded poly(lactic acid)/poly(ε-caprolactone) blends and comparison with conventional injection molding. RSC Adv 5:92905–92917

Yang L, Su J, Yang Q, Zhang T, Zhao Z, Huang Y, Liao X (2016) Effective in situ polyamide 6 microfibrils in isotactic polypropylene under microinjection molding: significant improvement of mechanical performance. J Mater Sci 51:10386–10399. https://doi.org/10.1007/s10853-016-0259-z

Spinella S, Cai J, Samuel C et al (2015) Polylactide/poly(ω-hydroxytetradecanoic acid) reactive blending: a green renewable approach to improving polylactide properties. Biomacromolecules 16:1818–1826

Eslami H, Kamal MR (2013) Elongational rheology of biodegradable poly(lactic acid)/poly[(butylene succinate)-co-adipate] binary blends and poly(lactic acid)/poly[(butylene succinate)-co-adipate]/clay ternary nanocomposites. J Appl Polym Sci 127:2290–2306

Kamal MR, El Otmani R, Derdouri A, Chu JS (2017) Flow and thermal history effects on morphology and tensile behavior of poly(oxymethylene) micro injection molded parts. Int Polym Proc 32:590–605

Chu JS, Kamal MR, Derdouri A, Hrymak A (2012) Morphology development in the gate region of microinjection-molded thermoplastics. Polym Eng Sci 52:787–794

Harris AM, Lee EC (2008) Improving mechanical performance of injection molded PLA by controlling crystallinity. J Appl Polym Sci 107:2246–2255

Cheng S, Lau KT, Liu T, Zhao Y, Lam PM, Yin Y (2009) Mechanical and thermal properties of chicken feather fiber/PLA green composites. Compos Part B Eng 40:650–654

Zhou S, Hrymak AN, Kamal MR (2016) Electrical and morphological properties of microinjection molded polystyrene/multiwalled carbon nanotubes nanocomposites. Polym Eng Sci 56:1182–1190

Motaghi A, Hrymak A, Motlagh GH (2015) Electrical conductivity and percolation threshold of hybrid carbon/polymer composites. J Appl Polym Sci 132:41744

Ojijo V, Ray SS, Sadiku R (2012) Role of specific interfacial area in controlling properties of immiscible blends of biodegradable polylactide and poly[(butylene succinate)-co-adipate]. ACS Appl Mater Inter 4:6690–6701

Eslami H, Kamal MR (2013) Effect of a chain extender on the rheological and mechanical properties of biodegradable poly(lactic acid)/poly[(butylene succinate)-co-adipate] blends. J Appl Polym Sci 129:2418–2428

Jiang Z, Chen Y, Liu Z (2014) The morphology, crystallization and conductive performance of a polyoxymethylene/carbon nanotube nanocomposite prepared under microinjection molding conditions. J Polym Res 21:451

Ray SS, Bandyopadhyay J, Bousmina M (2007) Thermal and thermomechanical properties of poly[(butylene succinate)-co-adipate] nanocomposite. Polym Degrad Stabil 92:802–812

Liu Z, Chen Y, Ding W, Zhang C (2015) Filling behavior, morphology evolution and crystallization behavior of microinjection molded poly(lactic acid)/hydroxyapatite nanocomposites. Compos Part A Appl S 72:85–95

Zhang J, Duan Y, Sato H, Tsuji H, Noda I, Yan S, Ozaki Y (2005) Crystal modifications and thermal behavior of poly(L-lactic acid) revealed by infrared spectroscopy. Macromolecules 38:8012–8021

Lee S, Lee JW (2005) Characterization and processing of biodegradable polymer blends of poly(lactic acid) with poly(butylene succinate adipate). Korea Aust Rheol J 17:71–77

Han Z, Fina A (2011) Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review. Prog Polym Sci 36:914–944

Zhou S, Yu L, Song X, Chang J, Zou H, Liang M (2014) Preparation of highly thermally conducting polyamide 6/graphite composites via low-temperature in situ expansion. J Appl Polym Sci 131:39596

Tu C, Nagata K, Yan S (2017) Influence of melt-mixing processing sequence on electrical conductivity of polyethylene/polypropylene blends filled with graphene. Polym Bull 74:1237–1252

Wu D, Lin D, Zhang J et al (2011) Selective localization of nanofillers: effect on morphology and crystallization of PLA/PCL blends. Macromol Chem Phys 212:613–626

Barber AH, Cohen SR, Wagner HD (2004) Static and dynamic wetting measurements of single carbon nanotubes. Phys Rev Lett 92:186103

Acknowledgements

This work was financially supported by Natural Sciences and Engineering Research Council of Canada and the Network for Innovative Plastic Materials and Manufacturing Processes. S.Z. acknowledges financial support from China Scholarship Council and technical support from Brad Kobe (Surface Science Western, The University of Western Ontario) for SEM observations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, S., Hrymak, A.N. & Kamal, M.R. Properties of microinjection-molded multi-walled carbon nanotubes-filled poly(lactic acid)/poly[(butylene succinate)-co-adipate] blend nanocomposites. J Mater Sci 53, 9013–9025 (2018). https://doi.org/10.1007/s10853-018-2193-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2193-8