Abstract

Development of mechanically flexible carbon nanofibers is highly desired for the applications in modern flexible electronics and energy storage devices. This work reports the manufacture and characterization of highly flexible carbon nanofibers (CNFs) and graphitic carbon nanofibers (GCNFs) from a non-processable heteroaromatic rigid-rod polymer, polybisbenzimidazobenzophenanthroline-dione (BBB). The flexible CNFs/GCNFs were prepared by a newly developed method of electrospun nanofiber template solid-state polymerization, followed by carbonization/graphitization. In specific, BBB nanofibers were prepared first by the nanofiber template solid-state polymerization method using polyimide as template by electrospinning and heat treatment (500 °C). Subsequently, CNFs/GCNFs were obtained through carbonization under different temperatures of 1200–2700 °C. SEM, HRTEM, Raman spectroscopy, and XRD were used to characterize the morphologies and microstructures. Intriguingly, the BBB-derived CNFs/GCNFs presented extremely good mechanical flexibility that resisting to readily bending, folding, and kneading. Hence, this newly developed extremely flexible BBB-derived CNFs/GCNFs with such good performance could have great potential applications such as using as electrode materials for flexible electrochemical devices.

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

Zhang J, Terrones M, Park CR, Mukherjee R, Monthioux M, Koratkar N, Kim YS, Hurt R et al (2016) Carbon science in 2016: status, challenges and perspectives. Carbon 98:708–732

Minus MM, Kumar S (2005) The processing, properties, and structure of carbon fibers. JOM 57:52–58

Chand S (2000) Review carbon fibers for composites. J Mater Sci 35:1303–1313. https://doi.org/10.1023/A:1004780301489

Soutis C (2005) Carbon fiber reinforced plastics in aircraft construction. Mater Sci Eng A 412:171–176

Hiremath N, Mays J (2017) Bhat G Recent developments in carbon fibers and carbon nanotube-based fibers: a review. Polym Rev 57:339–368

Inagaki M, Yang Y, Kang F (2012) Carbon nanofibers prepared via electrospinning. Adv Mater 24:2547–2566

Zhang L, Aboagye A, Kelkar A, Lai C, Fong H (2013) A review: carbon nanofibers from electrospun polyacrylonitrile and their applications. J Mater Sci 49:463–480. https://doi.org/10.1007/s10853-013-7705-y

Zhang B, Kang F, Tarascon JM, Kim JK (2016) Recent advances in electrospun carbon nanofibers and their application in electrochemical energy storage. Prog Mater Sci 76:319–380

Chen S, Hou H, Harnisch F, Patil SA, Carmona-Martinez AA, Agarwal S, Zhang Y, Sinha-Ray S, Yarin AL, Greiner A, Schroder U (2011) Electrospun and solution blown three-dimensional carbon fiber nonwovens for application as electrodes in microbial fuel cells. Energy Environ Sci 4:1417–1421

Guo Q, Zhou X, Li X, Chen S, Agarwal S, Greiner A, Hou H (2009) Supercapacitors based on hybrid carbon nanofibers containing multiwalled carbon nanotubes. J Mater Chem 19(2810):2816

Huang J, Wang D, Hou H, You T (2008) Electrospun palladium nanoparticle-loaded carbon nanofibers and their electrocatalytic activities towards hydrogen peroxide and NADH. Adv Funct Mater 18:441–448

Liu Q, Wang Y, Dai L, Yao J (2016) Scalable fabrication of nanoporous carbon fiber films as bifunctional catalytic electrodes for flexible Zn–Air batteries. Adv Mater 28:3000–3006

Huang J, Liu Y, Hou H, You T (2008) Simultaneous electrochemical determination of dopamine, uric acid and ascorbic acid using palladium nanoparticle-loaded carbon nanofibers modified electrode. Biosens Bioelectron 24:632–637

Liu Y, Huang J, Hou H, You T (2008) Simultaneous determination of dopamine, ascorbic acid and uric acid with electrospun carbon nanofibers modified electrode. Electrochem Commun 10:1431–1434

Chen Q, Wu W, Zhao Y, Xi M, Xu T, Fong H (2014) Nano-epoxy resins containing electrospun carbon nanofibers and the resulting hybrid multi-scale composites. Compos B 58:43–53

Che G, Lakshmi BB, Martin CR, Fisher ER, Ruoff RS (1998) Chemical vapor deposition based synthesis of carbon nanotubes and nanofibers using a template method. Chem Mater 10:260–267

De Jong KP, Geus JW (2000) Carbon nanofibers: catalytic synthesis and applications. Catal Rev 42:481–510

Sinha-Ray S, Yarin AL, Pourdeyhimi B (2010) The production of 100/400 nm inner/outer diameter carbon tubes by solution blowing and carbonization of core–shell nanofibers. Carbon 48:3575–3578

Duan G, Zhang H, Jiang S, Xie M, Peng X, Chen S, Hanif M, Hou H (2014) Modification of precursor polymer using co-polymerization: a good way to high performance electrospun carbon nanofiber bundles. Mater Lett 122:178–181

Kim C, Kim YJ, Kim YA (2004) Fabrication and structural characterization of electro-spun polybenzimidazol-derived carbon nanofiber by graphitization. Solid State Commun 132:567–571

Yang KS, Edie DD, Lim DY, Kim YM, Choi YO (2003) Preparation of carbon fiber web from electrostatic spinning of PMDA-ODA poly (amic acid) solution. Carbon 41:2039–2046

Kim C, Cho YJ, Yun WY, Ngoc BTN, Yang KS, Chang DR, Lee JW, Kojima M et al (2007) Fabrications and structural characterization of ultra-fine carbon fibres by electrospinning of polymer blends. Solid State Commun 142:20–23

Gibbs WE (1968) Some recent results on the synthesis of certain aromatic heterocyclic polymers. J Macromol Sci Chem 2:1291–1302

Van Deusen RL (1966) Benzimidazo-benzophenanthroline polymers. J Polym Sci B Polym Lett 4:211–214

Berry GC, Fox TG (1969) Properties of heterocyclic condensation polymers. J Macromol Sci Chem 3:1125–1146

Berry GC, Murakami M (1976) The viscosity of concentrated solutions of a heterocyclic polymer (BBB). J Polym Sci B Polym Phys 14:1721–1724

Zhu J, Ding Y, Agarwal S, Greiner A, Zhang H, Hou H (2017) Nanofibre preparation of non-processable polymers by solid-state polymerization of molecularly self-assembled monomers. Nanoscale 9:18169–18174

Huang C, Chen S, Reneker DH, Lai C, Hou H (2006) High-strength mats from electrospun poly(p-phenylene biphenyltetracarboximide) nanofibers. Adv Mater 18:668–671

He Y, Han D, Chen J, Ding Y, Jiang S, Hu C, Chen S, Hou H (2014) Highly strong and highly tough electrospun polyimide/polyimide composite nanofibers from binary blend of polyamic acids. RSC Adv 4:59936–59942

Jiang S, Duan G, Chen L, Hu X, Hou H (2015) Mechanical performance of aligned electrospun polyimide nanofiber belt at high temperature. Mater Lett 140:12–15

Chen S, Hu P, Greiner A, Cheng C, Cheng H, Chen F, Hou H (2008) Electrospun nanofiber belts made from high performance copolyimide. Nanotechnology 19:015604

Ding Y, Hou H, Zhao Y, Zhu Z, Fong H (2016) Electrospun polyimide nanofibers and their applications. Prog Polym Sci 61:67–103

Zhou Z, Lai C, Zhang L, Qian Y, Hou H, Reneker DH, Fong H (2009) Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanical properties. Polymer 50:2999–3006

Zhou Z, Liu K, Lai C, Zhang L, Li J, Hou H, Reneker DH, Fong H (2010) Graphitic carbon nanofibers developed from bundles of aligned electrospun polyacrylonitrile nanofibers containing phosphoric acid. Polymer 51:2360–2367

Saito Y, Yoshikawa T, Bandow S, Tomita M, Hayashi T (1993) Interlayer spacings in carbon nanotubes. Phys Rev B 48:1907–1909

Zhou S, Zhou G, Jiang S, Fan P, Hou H (2017) Flexible and refractory tantalum carbide-carbon electrospun nanofibers with high modulus and electric conductivity. Mater Lett 200:97–100

Arshad SN, Naraghi M, Chasiotis I (2011) Strong carbon nanofibers from electrospun polyacrylonitrile. Carbon 49:1710–1719

Acknowledgements

We are grateful to the financial support from National Natural Science Foundation of China (Grants No. 21564008), the Major Special Projects of Jiangxi Provincial Department of Science and Technology (Grant No.: 20114ABF05100), and the Technology Plan Landing Project of Jiangxi Provincial Department of Education (GCJ2011-243).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict.

Electronic supplementary material

Below is the link to the electronic supplementary material.

10853_2018_2191_MOESM1_ESM.docx

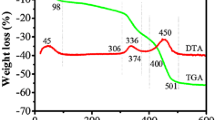

The online version of this article contains supplementary material (synthesis of PAA; TGA curve of NTCA–DAB/PAA nanofibers; XPS spectra of BBB-PI and CNFs nanofibers; photographs demonstrating the flexibility of CNFs; stress-strain curves; detailed Raman and XRD analysis), which is available to authorized users. (DOCX 1759 kb)

Supplementary material 3 (AVI 8991 kb)

Supplementary material 4 (AVI 8914 kb)

Supplementary material 5 (AVI 7627 kb)

Supplementary material 6 (AVI 8588 kb)

Supplementary material 7 (AVI 8765 kb)

Rights and permissions

About this article

Cite this article

Zhu, J., Ding, Y., Liao, X. et al. Highly flexible electrospun carbon/graphite nanofibers from a non-processable heterocyclic rigid-rod polymer of polybisbenzimidazobenzophenanthroline-dione (BBB). J Mater Sci 53, 9002–9012 (2018). https://doi.org/10.1007/s10853-018-2191-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2191-x