Abstract

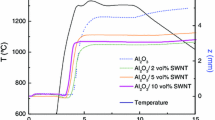

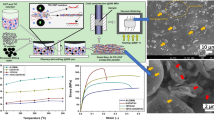

Fully pure nano-α-alumina (Al2O3) was prepared following gel-combustion method. Near theoretically dense monolithic Al2O3 and its composites reinforced with multiwalled carbon nanotubes (MWCNTs) were prepared using spark plasma sintering (SPS) at 1500 °C under 40 MPa within 10 min. The shrinkage curves were guided in sequence by the crystallization of the amorphous mass followed by a solid-state sintering. The differential nature of electrical conductivity of both composite phases resulted in enhanced densification through localized joule heating. Formation of ~ 1-μm-sized equiaxed matrix grains with uniform distribution of structurally survived CNTs in it was observed in the sintered composites. Within the investigated loading span, the highest Vickers hardness (HV) values were obtained only at 0.5 wt% MWCNT loading in matrix Al2O3. Improvements in HV values for the composites at 0.2 and 2 kgf indentation loads were found to be ~ 18 and ~ 12%, respectively, in comparison with those obtained for pure matrix phase. Quantitative indentation size effect analyzed through standard mathematical models indicated the role of matrix grain refinement and proper matrix–filler load sharing in changing the true hardness. On the contrary, increased CNT concentration leaded to increased sensitivity toward size effect due to the extreme flexible nature of the filler. Unlubricated linear scratch experiments revealed ~ 30–45% lower specific wear rate (WR) values of the composite specimens compared to SPS-processed monolithic Al2O3. Microstructure and scar profile observations were utilized to describe such enhanced wear resistance of present composites.

Similar content being viewed by others

References

Milak PC, Minatto FD, De Noni G Jr., Montedo ORK (2015) Wear performance of alumina-based ceramics—a review of the influence of microstructure on erosive wear. Cerâmica 61:88–103

Al-Sanabani FA, Madfa AA, Al-Qudaimi NH (2014) Alumina ceramic for dental applications: a review article. Am J Mater Res 1:26–34

Silva MV, Stainer D, Al-Qureshi HA, Montedo ORK, Hotza D (2014) Alumina-based ceramics for armor application: mechanical, characterization and ballistic testing. J Ceram 2014:618154

da Costa Evangelista JP, Gondim AD, Di Souza L, Araujo AS (2016) Alumina-supported potassium compounds as heterogeneous catalysts for biodiesel production: a review. Renew Sustain Energy Rev 59:887–894

Munro RG (1997) Evaluated material properties for a sintered α-alumina. J Am Ceram Soc 80:1919–1928

Galusek D, Galusková D (2015) Alumina matrix composites with non-oxide nanoparticle addition and enhanced functionalities. Nanomaterials 5:115–143

Bocanegra-Bernal MH, Dominguez-Rios C, Echeberria J, Reyes-Rojas A, Garcia-Reyes A, Aguilar-Elguezabal A (2016) Spark plasma sintering of multi-, single/double-and single-walled carbon nanotube-reinforced alumina composites: is it justifiable the effort to reinforce them? Ceram Int 42:2054–2062

Ahmad K, Pan W (2015) Microstructure-toughening relation in alumina based multiwall carbonnanotube ceramic composites. J Eur Ceram Soc 35:663–671

Yazdani B, Xia Y, Ahmad I, Zhu Y (2015) Graphene and carbon nanotube (GNT)-reinforced alumina nanocomposites. J Eur Ceram Soc 35:179–186

Yazdani B, Xu F, Ahmad I, Hou X, Xia Y, Zhu Y (2015) Tribological performance of graphene/carbon nanotube hybrid reinforced Al2O3 composites. Sci Rep 5:11579

Gallardo-López A, Poyato R, Morales-Rodríguez A, Fernández-Serrano A, Munoz A, Domı´nguez-Rodríguez A (2014) Hardness and flexural strength of single-walled carbon, nanotube/alumina composites. J Mater Sci 49:7116–7123. https://doi.org/10.1007/s10853-014-8419-5

Sarkar S, Das PK (2012) Microstructure and physicomechanical properties of pressureless sintered multiwalled carbon nanotube/alumina nanocomposites. Ceram Int 38:423–432

An J-W, You D-H, Lim D-S (2003) Tribological properties of hot-pressed alumina–CNT composites. Wear 255:677–681

Lim D-S, You D-H, Choi H-J, Lim S-H, Jang H (2005) Effect of CNT distribution on tribological behavior of alumina–CNT composites. Wear 259:539–544

Kim SW, Chung WS, Sohn K-S, Son C-Y, Lee S (2010) Improvement of wear resistance in alumina matrix composites reinforced with carbon nanotubes. Metall Mater Trans A 41A:380–388

Halder R, Bandyopadhyay S (2017) Synthesis and optical properties of anion deficient nano MgO. J Alloys Compd 693:534–542

Aliev AE, Lima MH, Silverman EM, Baughman RH (2010) Thermal conductivity of multi-walled carbon nanotube sheets: radiation losses and quenching of phonon modes. Nanotechnology 21:035709

Kajiura H, Tsutsui S, Huang H, Murakami Y (2002) High-quality single-walled carbon nanotubes from arc-produced soot. Chem Phys Lett 364:586–592

Suzuki T, Inoue S, Ando Y (2008) Purification of single-wall carbon nanotubes by using high-pressure micro reactor. Diam Relat Mater 17:1596–1599

Bertoncini M, Coelho LAF, Maciel IO, Pezzin SH (2011) Purification of single-wall carbon nanotubes by heat treatment and supercritical extraction. Mater Res 14:380–383

Sarkar S, Das PK (2013) Thermal and structural stability of single- and multi-walled carbon nanotubes up to 1800 °C in Argon studied by Raman spectroscopy and transmission electron Microscopy. Mater Res Bull 48:41–47

Hanzel O, Sedlácek J, Sajgalík P (2014) New approach for distribution of carbon nanotubes in alumina matrix. J Eur Ceram Soc 34:1845–1851

Ando Y, Zhao X, Shimoyama H, Sakai G, Kaneto K (1999) Physical properties of multiwalled carbon nanotubes. Int J Inorganic Mater 1:77–82

McEuen PL, Fuhrer MS, Park H (2002) Single-walled carbon nanotube electronics. IEEE Trans Nanotechnol 1:78–85

Huang Q, Jiang D, Ovidko IA, Mukherjee A (2010) High-current-induced damage on carbon nanotubes: the case during spark plasma sintering. Scripta Mater 63:1181–1184

Yamamoto G, Omori M, Yokomizo K, Hashida T (2008) Mechanical properties and structural characterization of carbon nanotube/alumina composites prepared by precursor method. Diam Relat Mater 17:1554–1557

Bi S, Hou G, Su X, Zhang Y, Guo F (2011) Mechanical properties and oxidation resistance of α-alumina/multi-walled carbon nanotube composite ceramics. Mater Sci Eng, A 528:1596–1601

Bi S, Su X, Hou G, Liu C, Song W-L, Cao M-S (2013) Electrical conductivity and microwave absorption of shortened multi-walled carbon nanotube/alumina ceramic composites. Ceram Int 39:5979–5983

Kasperski A, Weibel A, Estournès C, Laurent Ch, Peigney A (2013) Preparation-microstructure-property relationships in double-walled carbon nanotubes/alumina composites. Carbon 53:62–72

Michálek M, Sedláček J, Parchoviansky M, Michálková M, Galusek D (2014) Mechanical properties and electrical conductivity of alumina/MWCNT and alumina/zirconia/MWCNT composites. Ceram Int 40:1289–1295

Bakhsh N, Khalid FA, Hakeem AS (2013) Synthesis and characterization of pressureless sintered carbon nanotube reinforced alumina nanocomposites. Mater Sci Eng, A 578:422–429

Puchy V, Hvizdos P, Dusza J, Kovac F, Inam F, Reece MJ (2013) Wear resistance of Al2O3–CNT ceramic nanocomposites at room and high temperatures. Ceram Int 39:5821–5826

Thomson KE, Jiang D, Yao W, Ritchie RO, Mukherjee AK (2012) Characterization and mechanical testing of alumina-based nanocomposites reinforced with niobium and/or carbon nanotubes fabricated by spark plasma sintering. Acta Mater 60:622–632

Zhang SC, Fahrenholtz WG, Hilmas GE, Yadlowsky EJ (2010) Pressureless sintering of carbon nanotube–Al2O3 composites. J Eur Ceram Soc 30:1373–1380

Jiang D, Thomson K, Kuntz JD, Ager JW, Mukherjee AK (2007) Effect of sintering temperature on a single-wall carbon nanotube-toughened alumina-based nanocomposite. Scripta Mater 56:959–962

Echeberria J, Rodríguez N, Vleugels J, Vanmeensel K, Reyes-Rojas A, Garcia-Reyes A, Domínguez-Rios C, Aguilar-Elguézabal A, Bocanegra-Bernal MH (2012) Hard and tough carbon nanotube-reinforced zirconia-toughened alumina composites prepared by spark plasma sintering. Carbon 50:706–717

Ahmad I, Unwin M, Cao H, Chen H, Zhao H, Kennedy A, Zhu YQ (2010) Multi-walled carbon nanotubes reinforced Al2O3 nanocomposites: mechanical properties and interfacial investigations. Compos Sci Technol 70:1199–1206

Aguilar-Elguézabal A, Bocanegra-Bernal MH (2014) Fracture behaviour of α-Al2O3 ceramics reinforced with a mixture of single-wall and multi-wall carbon nanotubes. Compos Part B 60:463–470

Li H, Bradt RC (1993) The microhardness indentation load/size effect in rutile and cassiterite single crystals. J Mater Sci 28:917–926. https://doi.org/10.1007/BF00400874

Gong J, Wu J, Guan Z (1999) Examination of the indentation size effect in low-load vickers hardness testing of ceramics. J Eur Ceram Soc 19:2625–2631

Acknowledgements

The first author conveys sincere thanks to CSIR for Research Associate position. Helps from the institutional characterization units are gratefully acknowledged. Thanks are due to the Director of CSIR-Central Glass & Ceramic Research Institute, for his interest.

Funding

This study was funded by Council of Scientific and Industrial Research (CSIR), India (Grant Number: MLP-0202).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest related to this work.

Rights and permissions

About this article

Cite this article

Halder, R., Sarkar, S., Bandyopadhyay, S. et al. Sintering and tribomechanical properties of gel-combustion-derived nano-alumina and its composites with carbon nanotubes. J Mater Sci 53, 8989–9001 (2018). https://doi.org/10.1007/s10853-018-2187-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2187-6