Abstract

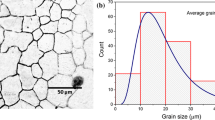

To investigate the mechanical behavior of AZ61 alloy in a mushy state, uniaxial tensile tests of as-extruded AZ61 alloy have been implemented at temperatures of 475–575 °C at a strain rate of 3 s−1. Experimental results show that zero strength and zero ductility emerged at 575 and 525 °C, respectively. Abnormal coarse grains with sugar-like morphology and molten Mg17Al12 phases were observed in the brittle temperature range. The grain boundaries and surface were gradually covered partially or completely by a liquefied microstructure as temperatures increased. Small micropores developed into short cracks at temperatures above 525 °C and then to large cracks throughout the grain boundaries at 575 °C. It is therefore suggested that crack propagation was controlled by the quantity and distribution of molten phase in the mushy zone. Three types of interfacial wedge cracks are applied to explicate the fracture behavior of the alloy at elevated temperatures.

Similar content being viewed by others

References

Luo AA (2013) Applications: aerospace, automotive and other structural applications of magnesium. In: Pekguleryuz MO, Kainer KU, Kaya AA (eds) Fundamentals of magnesium alloy metallurgy. Woodhead, Cambridge, pp 266–316

Mordike BL (2001) Development of highly creep resistant magnesium alloys. J Mater Process Tech 117:391–394

Stjohn DH, Easton MA, Qian M, Taylor JA (2013) Grain refinement of magnesium alloys: a review of recent research, theoretical developments, and their application. Metall Mater Trans A 44:2935–2949

Luo A, Pekguleryuz MO (1994) Cast magnesium alloys for elevated temperature applications. J Mater Sci 29:5259–5271. https://doi.org/10.1007/BF01171534

Yu Y, Arai K, Itoh S, Kamado S, Kojima Y (2005) Realization of high strength and high ductility for AZ61 magnesium alloy by severe warm working. Sci Technol Adv Mater 6:185–194

Koh Y, Kim D, Seok DY, Bak J, Kim SW, Lee YS, Chung K (2015) Characterization of mechanical property of magnesium az31 alloy sheets for warm temperature forming. Int J Mech Sci 93:204–217

Chino Y, Kimura K, Mabuchi M (2008) Twinning behavior and deformation mechanisms of extruded AZ31 mg alloy. Mater Sci Eng A 486:481–488

Zhu SQ, Yan HG, Xia WJ, Liu JZ, Jiang JF (2009) Influence of different deformation processing on the AZ31 magnesium alloy sheets. J Mater Sci 44:3800–3806. https://doi.org/10.1007/s10853-009-3513-9

Li L, Zheng M (2015) Theoretical research on rheological behavior of semisolid slurry of magnesium alloy AZ91D. Comput Mater Sci 102:202–207

Meng Y, Fukushima S, Sugiyama S, Yanagimoto J (2015) Cold formability of AZ31 wrought magnesium alloy undergoing semisolid spheroidization treatment. Mater Sci Eng A 624:148–156

Kleiner S, Ogris E, Beffort O, Uggowitzer PJ (2010) Semi-solid metal processing of aluminum alloy A356 and magnesium alloy AZ91: comparison based on metallurgical consideration. Adv Eng Mater 5:653–658

Flemings MC (1991) Behavior of metal alloys in the semisolid state. Metall Trans A 22:269–293

Dahle AK, Suéry M (2010) Deformation Behavior of Aluminum Alloys during Solidification. Mater Sci Forum 649:337–342

Rauh H, Hippsley CA, Bullough R (1989) The effect of mixed-mode loading on stress-driven solute segregation during high-temperature brittle intergranular fracture. Acta Metall 37:269–279

Sinha S, Kim DI, Fleury E, Suwas S (2015) Effect of grain boundary engineering on the microstructure and mechanical properties of copper containing austenitic stainless steel. Mater Sci Eng A 626:175–185

Nesterova EV, Bouvier S, Bacroix B (2015) Microstructure evolution and mechanical behavior of a high strength dual-phase steel under monotonic loading. Mater Charact 100:152–162

Hippsley CA (2013) Brittle intergranular fracture at elevated temperatures in low-alloy steel. Mater Sci Tech 1:475–479

Molina R, Aluminum Amalberto P, Rosso-Politecnico M, Di T (2011) Mechanical characterization of aluminium alloys for high temperature applications part1: Al–Si–Cu alloys. Metall Sci Tecn 14:1650–1656

Jiang B, Liu WJ, Chen SQ, Yang QS, Pan FS (2011) Mechanical properties and microstructure of as-extruded AZ31 mg alloy at high temperatures. Mater Sci Eng A 530:51–56

Li M, Tamura T, Omura N, Miwa K (2010) The solidification behavior of the AZ61 magnesium alloy during electromagnetic vibration processing. J Alloys Compd 494:116–122

Olguín-González ML, Hernández-Silva D, García-Bernal MA, Sauce-Rangel VM (2014) Hot deformation behavior of hot-rolled AZ31 and AZ61 magnesium alloys. Mater Sci Eng A 597:82–88

Yan H, Zhou B (2006) Thixotropic deformation behavior of semi-solid AZ61 magnesium alloy during compression process. Mater Sci Eng B 132:179–182

Anaraki MT, Sanjari M, Akbarzadeh A (2008) Modeling of high temperature rheological behavior of AZ61 mg-alloy using inverse method and ANN. Mater Des 29:1701–1706

Xu Y, Hu L, Sun Y (2013) Deformation behaviour and dynamic recrystallization of AZ61 magnesium alloy. J Alloys Compd 580:262–269

Tsao LC, Chen CH, Wu RW, Chang SY, Chen RS (2015) Plastic flow behavior, microstructure, and corrosion behavior of AZ61 mg alloy during hot compression deformation. J Manuf Processes 18:167–174

Liao C, Wu H, Wu C, Zhu F, Lee S (2014) Hot deformation behavior and flow stress modeling of annealed az61 mg alloys. Prog Nat Sci: Mater Int 24:253–265

Acknowledgements

The authors are grateful for the financial supports from the Chongqing Science and Technology Commission (cstc2013jcyjC60001, cstc2014jcyjjq0041, cstc2014jcyjjq50002, and cstc2013jcyjA50030); the National Natural Science Foundation of China (51701035, 51531002, 51171212, and 51474043); and the National Science and Technology Program of China (2013CB632200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, W., Jiang, B., Luo, S. et al. Mechanical properties and failure behavior of AZ61 magnesium alloy at high temperatures. J Mater Sci 53, 8536–8544 (2018). https://doi.org/10.1007/s10853-018-2125-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2125-7