Abstract

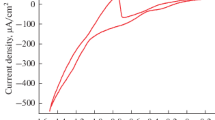

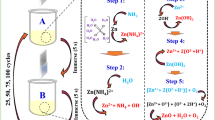

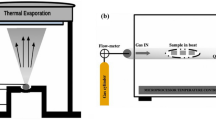

Nanophase zinc oxide (ZnO) has been widely studied as an important multifunctional material in many applications. Atomic layer deposition (ALD) is a unique thin-film synthesis technique, featuring its extreme uniformity, unrivaled conformal coverage, low deposition temperature, and precise controllability. Using diethylzinc (DEZ) and water as precursors, ALD has been reported previously for growing nanophase ZnO thin films. However, the growth characteristics and the resultant ZnO crystallinity have not been well characterized and understood. To this end, we revisited the ALD process of ZnO using DEZ and water. Through employing a suite of advanced characterization techniques, we systematically addressed the growth characteristics, morphological changes, and the crystallinity evolution of ZnO along with growth temperature in the range of 30–250 °C. The growth characteristics of the ALD ZnO films were investigated using in situ quartz crystal microbalance (QCM), scanning electron microscopy, atomic force microscopy, and synchrotron-based X-ray reflectivity. The crystallinity of the ALD ZnO films was determined using synchrotron-based X-ray diffraction and high-resolution transmission electron microscopy. In addition, through further analyzing QCM data, we proposed the adsorption-limited surface reaction for ALD ZnO growth with the temperature-dependent number of –OH surface group reacting with one DEZ molecule. Thus, this study contributes to offer new and deep insights on the fundamental ALD process of ZnO.

Similar content being viewed by others

References

Morkoç H, Özgür Ü (2008) Zinc oxide: fundamentals, materials and device technology. Wiley, Hoboken

Özgür Ü et al (2005) A comprehensive review of ZnO materials and devices. J Appl Phys 98(4):041301

Desgreniers S (1998) High-density phases of ZnO: structural and compressive parameters. Phys Rev B 58(21):14102

Karzel H et al (1996) Lattice dynamics and hyperfine interactions in ZnO and ZnSe at high external pressures. Phys Rev B 53(17):11425–11438

Jaffe J, Hess A (1993) Hartree-Fock study of phase changes in ZnO at high pressure. Phys Rev B 48(11):7903–7909

Dixit H et al (2010) The quasiparticle band structure of zincblende and rocksalt ZnO. J Phys Cond Matter 22(12):125505

Pung S, Choy K, Hou X (2013) Growth of (002)–oriented ZnO thin films on largely lattice–mismatched substrates using atomic layer deposition. Int J Nanotechnol 10(3–4):247–259

Bunn C (1935) The lattice-dimensions of zinc oxide. Proc Phys Soc 47(5):835–842

Ng HT et al (2004) Single crystal nanowire vertical surround-gate field-effect transistor. Nano Lett 4(7):1247–1252

Könenkamp R, Word RC, Schlegel C (2004) Vertical nanowire light-emitting diode. Appl Phys Lett 85(24):6004–6006

Park H et al (2018) Electro-optical properties of liquid crystal displays based on the transparent zinc oxide films treated by using a rubbing method. Opt Mater 75:252–257

Al-Senany N et al (2014) Negative resistance behaviour and molecular reorientation properties of zinc oxide nanoparticles based liquid crystals for high image quality liquid crystal displays. J Nanoelectron Optoelectron 9(5):640–643

Zang Z et al (2016) Femtosecond laser direct writing of microholes on roughened ZnO for output power enhancement of InGaN light-emitting diodes. Opt Lett 41(15):3463–3466

Zhang Y et al (2014) Flexible paper-based ZnO nanorod light-emitting diodes induced multiplexed photoelectrochemical immunoassay. Chem Commun 50(12):1417–1419

Pearton S, Ren F (2014) Advances in ZnO-based materials for light emitting diodes. Curr Opin Chem Eng 3:51–55

Esro M et al (2015) High-mobility ZnO thin film transistors based on solution-processed hafnium oxide gate dielectrics. Adv Func Mater 25(1):134–141

Lin Y et al (2015) Stable and high-performance flexible ZnO thin-film transistors by atomic layer deposition. ACS Appl Mater Interfaces 7(40):22610–22617

Sisman Z, Bolat S, Okyay AK (2017) Atomic layer deposition for vertically integrated ZnO thin film transistors: toward 3D high packing density thin film electronics. Phys Status Solidi (C) 14(9):1700128

Park SK, Lee YE (2004) Controlling preferred orientation of ZnO thin films by atomic layer deposition. J Mater Sci 39(6):2195–2197. https://doi.org/10.1023/B:JMSC.0000017786.81842.ae

Malm J et al (2011) Low-temperature atomic layer deposition of ZnO thin films: control of crystallinity and orientation. Thin Solid Films 519(16):5319–5322

Gorla C et al (1999) Structural, optical, and surface acoustic wave properties of epitaxial ZnO films grown on (0112) sapphire by metalorganic chemical vapor deposition. J Appl Phys 85(5):2595–2602

Jagadish C, Pearton SJ (2011) Zinc oxide bulk, thin films and nanostructures: processing, properties, and applications. Elsevier, Amsterdam

Janotti A, Van de Walle CG (2009) Fundamentals of zinc oxide as a semiconductor. Rep Prog Phys 72(12):126501

Karpina V et al (2004) Zinc oxide–analogue of GaN with new perspective possibilities. Cryst Res Technol 39(11):980–992

Zou F et al (2014) MOF-derived porous ZnO/ZnFe2O4/C octahedra with hollow interiors for high-rate lithium-ion batteries. Adv Mater 26(38):6622–6628

Xie Q et al (2014) Yolk-shell ZnO–C microspheres with enhanced electrochemical performance as anode material for lithium ion batteries. Electrochim Acta 125:659–665

Osmond G (2012) Zinc white: a review of zinc oxide pigment properties and implications for stability in oil-based paintings. AICCM Bull 33(1):20–29

Zabinski J et al (1997) Lubricious zinc oxide films: synthesis, characterization and tribological behaviour. J Mater Sci 32(20):5313–5319. https://doi.org/10.1023/A:1018614811131

Hultqvist A et al (2017) Atomic layer deposition of electron selective SnOx and ZnO films on mixed halide perovskite: compatibility and performance. ACS Appl Mater Interfaces 9(35):29707–29716

Kim H et al (2017) Oxidant-dependent thermoelectric properties of undoped ZnO films by atomic layer deposition. Chem Mater 29(7):2794–2802

Daubert JS et al (2017) Corrosion protection of copper using Al2O3, TiO2, ZnO, HfO2, and ZrO2 atomic layer deposition. ACS Appl Mater Interfaces 9(4):4192–4201

Chai Z, Lu X, He D (2012) Atomic layer deposition of zinc oxide films: effects of nanocrystalline characteristics on tribological performance. Surf Coat Technol 207:361–366

Wang ZL (2004) Zinc oxide nanostructures: growth, properties and applications. J Phys Condens Matter 16(25):R829–R858

Cui J (2012) Zinc oxide nanowires. Mater Charact 64:43–52

Dai Y et al (2002) Synthesis and optical properties of tetrapod-like zinc oxide nanorods. Chem Phys Lett 358(1–2):83–86

Fouad O (2006) Growth of zinc oxide nanorods, tetrapods, and nanobelts without catalyst. J Nanosci Nanotechnol 6(7):2090–2094

Kulkarni A, Zhou M, Ke F (2005) Orientation and size dependence of the elastic properties of zinc oxide nanobelts. Nanotechnology 16(12):2749–2756

Abdulgafour H et al (2010) Growth of zinc oxide nanoflowers by thermal evaporation method. Phys. B 405(11):2570–2572

Becheri A et al (2008) Synthesis and characterization of zinc oxide nanoparticles: application to textiles as UV-absorbers. J Nanopart Res 10(4):679–689

Park WI (2008) Controlled synthesis and properties of ZnO nanostructures grown by metalorganic chemical vapor deposition: a review. Met Mater Int 14(6):659–665

Willander M et al (2009) Zinc oxide nanorod based photonic devices: recent progress in growth, light emitting diodes and lasers. Nanotechnology 20(33):332001

Triboulet R, Perrière J (2003) Epitaxial growth of ZnO films. Prog Cryst Growth Charact Mater 47(2–3):65–138

Kajikawa Y (2006) Texture development of non-epitaxial polycrystalline ZnO films. J Cryst Growth 289(1):387–394

Dem’Yanets L, Li L, Uvarova T (2006) Zinc oxide: hydrothermal growth of nano-and bulk crystals and their luminescent properties. J Mater Sci 41(5):1439–1444. https://doi.org/10.1007/s10853-006-7457-z

Chen S et al (2003) Preparation and characterization of nanocrystalline zinc oxide by a novel solvothermal oxidation route. J Cryst Growth 252(1–3):184–189

Knez M, Nielsch K, Niinistö L (2007) Synthesis and surface engineering of complex nanostructures by atomic layer deposition. Adv Mater 19(21):3425–3438

Knoops H et al (2012) Atomic layer deposition for nanostructured Li-ion batteries. J Vac Sci Technol A Vac Surf Films 30(1):010801

George S, Ott A, Klaus J (1996) Surface chemistry for atomic layer growth. J Phys Chem 100(31):13121–13131

Suntola T (1992) Atomic layer epitaxy. Thin Solid Films 216(1):84–89

Kucheyev S et al (2005) Atomic layer deposition of ZnO on ultralow-density nanoporous silica aerogel monoliths. Appl Phys Lett 86(8):083108

Zhang W et al (2015) Large scale synthesis of pinhole-free shell-isolated nanoparticles (SHINs) using improved atomic layer deposition (ALD) method for practical applications. J Raman Spectrosc 46(12):1200–1204

Yao Z et al (2015) AAO-assisted synthesis of highly ordered, large-scale TiO2 nanowire arrays via sputtering and atomic layer deposition. Nanoscale Res Lett 10(1):166

Klaus J, George S (2000) Atomic layer deposition of SiO2 at room temperature using NH3-catalyzed sequential surface reactions. Surf Sci 447(1–3):81–90

Mackus AJ et al (2013) Room-temperature atomic layer deposition of platinum. Chem Mater 25(9):1769–1774

Kot M et al (2016) Room-temperature atomic layer deposition of Al2O3: impact on efficiency, stability and surface properties in perovskite solar cells. Chemsuschem 9(24):3401–3406

Dücsö C et al (1996) Deposition of tin oxide into porous silicon by atomic layer epitaxy. J Electrochem Soc 143(2):683–687

Gordon RG et al (2003) A kinetic model for step coverage by atomic layer deposition in narrow holes or trenches. Chem Vap Depos 9(2):73–78

Solanki R et al (2002) Atomic layer deposition of ZnSe/CdSe superlattice nanowires. Appl Phys Lett 81(20):3864–3866

Gu D et al (2011) Precise control of highly ordered arrays of nested semiconductor/metal nanotubes. Nano Res 4(2):164–170

Qin Y et al (2010) Preparation and elastic properties of helical nanotubes obtained by atomic layer deposition with carbon nanocoils as templates. Small 6(8):910–914

Knez M et al (2006) Atomic layer deposition on biological macromolecules: metal oxide coating of tobacco mosaic virus and ferritin. Nano Lett 6(6):1172–1177

Bishal AK et al (2015) Atomic layer deposition in bio-nanotechnology: a brief overview. Crit Rev™ Biomed Eng 43(4):255–276

Kääriäinen TO et al (2011) Atomic layer deposition on polymer based flexible packaging materials: growth characteristics and diffusion barrier properties. Thin Solid Films 519(10):3146–3154

Ferguson J, Weimer A, George S (2004) Atomic layer deposition of Al2O3 films on polyethylene particles. Chem Mater 16(26):5602–5609

Jessensky O, Müller F, Gösele U (1998) Self-organized formation of hexagonal pore arrays in anodic alumina. Appl Phys Lett 72(10):1173–1175

King J et al (2003) High-filling-fraction inverted ZnS opals fabricated by atomic layer deposition. Appl Phys Lett 83(13):2566–2568

Shin H et al (2004) Formation of TiO2 and ZrO2 nanotubes using atomic layer deposition with ultraprecise control of the wall thickness. Adv Mater 16(14):1197–1200

Macák JM, Tsuchiya H, Schmuki P (2005) High-aspect-ratio TiO2 nanotubes by anodization of titanium. Angew Chem Int Ed 44(14):2100–2102

Knaut M et al (2013) Atomic layer deposition for high aspect ratio through silicon vias. Microelectron Eng 107:80–83

Lim BS, Rahtu A, Gordon RG (2003) Atomic layer deposition of transition metals. Nat Mater 2(11):749–754

Tynell T, Karppinen M (2014) Atomic layer deposition of ZnO: a review. Semicond Sci Technol 29(4):043001

Meng X et al (2011) Controllable synthesis of graphene-based titanium dioxide nanocomposites by atomic layer deposition. Nanotechnology 22(16):165602

Wind R, George S (2009) Quartz crystal microbalance studies of Al2O3 atomic layer deposition using trimethylaluminum and water at 125 C. J Phys Chem A 114(3):1281–1289

Becker JS, Kim E, Gordon RG (2004) Atomic layer deposition of insulating hafnium and zirconium nitrides. Chem Mater 16(18):3497–3501

Klug JA et al (2013) Heteroepitaxy of group IV-VI nitrides by atomic layer deposition. Appl Phys Lett 103(21):211602

Meng X et al (2014) Atomic layer deposition of gallium sulfide films using hexakis (dimethylamido) digallium and hydrogen sulfide. Chem Mater 26(2):1029–1039

Meng X et al (2017) Atomic layer deposition of aluminum sulfide: growth mechanism and electrochemical evaluation in lithium-ion batteries. Chem Mater 29(21):9043–9052

Lee HJ et al (2011) A high-performing nanostructured TiO2 filter for volatile organic compounds using atomic layer deposition. Chem Commun 47(19):5605–5607

Pore V et al (2009) Atomic layer deposition of metal tellurides and selenides using alkylsilyl compounds of tellurium and selenium. J Am Chem Soc 131(10):3478–3480

Wang H et al (2009) Atomic layer deposition of lanthanum-based ternary oxides. Electrochem Solid-State Lett 12(4):G13–G15

Tammenmaa M et al (1985) Zinc chalcogenide thin films grown by the atomic layer epitaxy technique using zinc acetate as source material. Thin Solid Films 124(2):125–128

Kopalko K et al (2005) Growth by atomic layer epitaxy and characterization of thin films of ZnO. Phys Stat Solidi (C) 2(3):1125–1130

Lujala V et al (1994) Atomic layer epitaxy growth of doped zinc oxide thin films from organometals. Appl Surf Sci 82:34–40

Krajewski T et al (2009) The influence of growth temperature and precursors’ doses on electrical parameters of ZnO thin films grown by atomic layer deposition technique. Microelectron J 40(2):293–295

Lee S et al (2006) Structural and optical properties of high quality ZnO films on Si grown by atomic layer deposition at low temperatures. Superlattices Microstruct 39(1–4):24–32

An K et al (2008) Atomic layer deposition of undoped and Al-doped ZnO thin films using the Zn alkoxide precursor methylzinc isopropoxide. J Nanosci Nanotechnol 8(9):4856–4859

Pung S et al (2008) Preferential growth of ZnO thin films by the atomic layer deposition technique. Nanotechnology 19(43):435609

Yousfi EB, Fouache J, Lincot D (2000) Study of atomic layer epitaxy of zinc oxide by in situ quartz crystal microgravimetry. Appl Surf Sci 153(4):223–234

Vohs J, Barteau M (1989) Photoelectron spectroscopy of diethylzinc on the polar surfaces of zinc oxide. J Electron Spectrosc Relat Phenom 49(1):87–96

Pradhan K, Lyman PF (2011) Study of atomic layer deposition of ZnO on a polar oxide substrate by in situ quartz crystal microbalance. ECS Trans 41(2):247–253

Meng X et al (2014) Vapor-phase atomic-controllable growth of amorphous Li2S for high-performance lithium–sulfur batteries. ACS Nano 8(10):10963–10972

Als-Nielsen J, McMorrow D (2011) Elements of modern X-ray physics. Wiley, Hoboken

Hu J, Gordon RG (1992) Atmospheric pressure chemical vapor deposition of gallium doped zinc oxide thin films from diethyl zinc, water, and triethyl gallium. J Appl Phys 72(11):5381–5392

Li X et al (2012) Tin oxide with controlled morphology and crystallinity by atomic layer deposition onto graphene nanosheets for enhanced lithium storage. Adv Func Mater 22(8):1647–1654

Meng X et al (2010) Non-aqueous approach to synthesize amorphous/crystalline metal oxide-graphene nanosheet hybrid composites. J Phys Chem C 114(43):18330–18337

Afshar A, Cadien KC (2013) Growth mechanism of atomic layer deposition of zinc oxide: a density functional theory approach. Appl Phys Lett 103(25):251906

Rueter M, Vohs J (1992) The surface reactions of ethyl groups on Si (100) formed via dissociation of adsorbed diethylzinc. Surf Sci 262(1–2):42–50

George SM (2009) Atomic layer deposition: an overview. Chem Rev 110(1):111–131

Acknowledgements

XM, JC, and MZ acknowledge the partial support from the Center for Advanced Surface Engineering, under the National Science Foundation Grant No. OIA-1457888 and the Arkansas EPSCoR Program, ASSET III. XM and JC also appreciate the financial research support from University of Arkansas, Fayetteville, AR, USA. This work was performed, in part, at the Advanced Photon Source and Center for Nanoscale Materials, both belonging to US Department of Energy Office of Science User Facility, and supported by the US Department of Energy, Office of Science, under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All authors declare no conflicts of interest in this paper.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cai, J., Ma, Z., Wejinya, U. et al. A revisit to atomic layer deposition of zinc oxide using diethylzinc and water as precursors. J Mater Sci 54, 5236–5248 (2019). https://doi.org/10.1007/s10853-018-03260-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-03260-3