Abstract

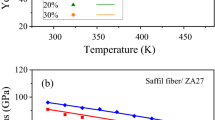

In this paper, based on our previous study regarding the temperature-dependent yield strength for metallic materials and the existing strengthening theories, a physics-based temperature dependent compressive yield strength model for short fiber reinforced magnesium alloy matrix composites was developed. This model was verified by comparison with the experimental data of seven types of magnesium alloy matrix composites. Good agreement between the model predictions and the experimental data was obtained, which fully validates the reasonability of the present model. Moreover, based on the model and the existing material parameters, the influencing factor analysis for short fiber reinforced magnesium alloy matrix composites was systematically conducted. Some novel insights regarding the control mechanism of their temperature dependent compressive yield strengths were provided.

Similar content being viewed by others

References

Jayalakshmi S, Kailas SV, Seshan S (2002) Tensile behaviour of squeeze cast AM100 magnesium alloy and its Al2O3 fibre reinforced composites. Compos Part A Appl Sci Manuf 33(8):1135–1140

Zhang XZ, Zhang Q, Hu H (2014) Tensile behaviour and microstructure of magnesium AM60-based hybrid composite containing Al2O3 fibres and particles. Mat Sci Eng A 607:269–276

Chen ZH (2007) Heat-proof magnesium alloy. Chemical Industry Press, Beijing

Dey A, Pandey KM (2015) Magnesium metal matrix composites—a review. Rev Adv Mater Sci 42:58–67

Trojanová Z, Gärtnerová V, Lukáč P, Drozd Z (2004) Mechanical properties of Mg alloys composites reinforced with short Saffil® fibres. J Alloy Compd 378(1):19–26

Trojanová Z, Száraz Z, Lábár J, Lukáč P (2005) Deformation behaviour of an AS21 alloy reinforced by short Saffil fibres and SiC particles. J Mater Process Tech 162:131–138

Trojanová Z, Száraz Z (2005) Mechanical properties of AS21 magnesium alloy based composites. Trans Tech Publ, Mater Sci Forum, pp 363–366

Trojanová Z, Drozd Z, Kúdela S, Száraz Z, Lukáč P (2007) Strengthening in Mg–Li matrix composites. Compos Sci Technol 67(9):1965–1973

Liu J, Qi LH, Zhang HY, Hou HP (2015) Effect of liquid–solid extrusion on the high-temperature compressive properties of Csf/Mg composites. Mater Manuf Process 30(11):1391–1396

Ataya S, El-Magd E (2007) Quasi-static behavior of Mg-alloys with and without short-fiber reinforcement. Theor Appl Fract Mech 47(2):102–112

Liu J, Qi LH, Guan JT, Ma YQ, Zhou JM (2012) Compressive behavior of Csf/AZ91D composites by liquid–solid extrusion directly following vacuum infiltration technique. Mat Sci Eng A 531:164–170

Rudajevová A, Lukáč P (2003) Thermal strain in Mg composites. Acta Mater 51(18):5579–5586

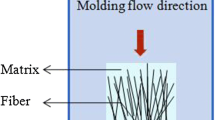

Farkas G, Trojanová Z, Száraz Z, Minárik P, Máthis K (2015) Effect of the fiber orientation on the deformation mechanisms of magnesium-alloy based composite. Mater Sci Eng A 643:25–31

Farkas G, Máthis K, Pilch J, Minárik P, Lukáš P, Vinogradov A (2017) Deformation behavior of Mg-alloy-based composites at different temperatures studied by neutron diffraction. Mater Sci Eng A 685:284–293

Karbhari VM, Wilkins DJ (1991) An “engineering” modification to the shear-lag model as applied to whisker and particulate reinforced composites. Scripta Metall Mater 25(3):707–712

Nardone VC, Prewo KM (1986) On the strength of discontinuous silicon carbide reinforced aluminum composites. Scripta Metall 20(1):43–48

Zhang CY, Qiu YP (2003) Modified shear lag model for fibers and fillers with irregular cross-sectional shapes. J Adhes Sci Technol 17(3):397–408

Ryu HJ, Cha SI, Hong SH (2003) Generalized shear-lag model for load transfer in SiC/Al metal-matrix composites. J Mater Res 18(12):2851–2858

Jiang ZH, Lian JS, Yang DZ, Dong SL (1998) An analytical study of the influence of thermal residual stresses on the elastic and yield behaviors of short fiber-reinforced metal matrix composites. Mat Sci Eng A 248(1–2):256–275

Arsenault RJ, Shi N (1986) Dislocation generation due to differences between the coefficients of thermal expansion. Mat Sci Eng 81:175–187

Clyne TW, Withers PJ (1993) An introduction to metal matrix composites. Cambridge University Press, Cambridge

Taylor GI (1934) The mechanism of plastic deformation of crystals. Part I. Theor Proc R Soc Lond Ser A 145(855):362–387

Ashby MF (1993) Criteria for selecting the components of composites. Acta Metall Mater 41(5):1313–1335

Luster JW, Thumann M, Baumann R (1993) Mechanical properties of aluminium alloy 6061–Al2O3 composites. Mater Sci Tech-lond 9(10):853–862

Lilholt H (1991) Aspects of deformation of metal matrix composites. Mat Sci Eng A 135:161–171

Hall EO (1951) The deformation and ageing of mild steel: III discussion of results. Proc Phys Soc Lond B 64(9):747–753

Petch NJ (1953) The cleavage strengh of polycrystals. J Iron Steel Inst 174:25–28

Zou ZX, Xiang JZ, Xu SY (2012) Theoretical derivation of Hall-Petch relationship and discussion of its applicable range. Phys Exam Test 30(6):13–17

Fu EG, Li N, Misra A, Hoagland RG, Wang H, Zhang X (2008) Mechanical properties of sputtered Cu/V and Al/Nb multilayer films. Mat Sci Eng A 493(1–2):283–287

Tang XF, Wang BY, Huo YM, Ma WY, Zhou J, Ji HC et al (2016) Unified modeling of flow behavior and microstructure evolution in hot forming of a Ni-based superalloy. Mat Sci Eng A 662:54–64

Zhang XH, Li WG, Ma JZ, Geng PJ, Shao JX, Wu XZ (2017) A novel temperature dependent yield strength model for metals considering precipitation strengthening and strain rate. Comp Mater Sci 129:147–155

Arsenault RJ, Taya M (1987) Thermal residual stress in metal matrix composite. Acta Metall 35(3):651–659

ASM International Handbook Committee (1990) ASM Handbook, volume 2, properties and selection: nonferrous alloys and special-purpose materials. ASM International, Materials Park, OH

Magnesium AS21-F, Die Cast, http://www.matweb.com/search/DataSheet.aspx?MatGUID=b910504d247f418e8e70a10ad0f549c2&ckck=1. Accessed 21 Oct 2017

Magnesium AE42-F, Die Cast, http://www.matweb.com/search/DataSheet.aspx?MatGUID=503232647ec44a408f191d57dd336ea5&ckck=1. Accessed 21 Oct 2017

Lavrentev FF, Pokhil YA, Zolotukhina IN (1978) Analysis of pairwise dislocation interaction and its contribution to flow stress during magnesium crystal basal slip. Mat Sci Eng 32(2):113–119

Murray JL (1982) The Al–Mg (aluminum–magnesium) system. J Phase Equilib 3(1):60–74

Luo A, Pekguleryuz MO (1994) Cast magnesium alloys for elevated temperature applications. J Mater Sci 29(20):5259–5271. https://doi.org/10.1007/BF01171534

Aune TK, Westengen H (1995) Property update on magnesium die casting alloys. SAE Technical Paper 950424

MIL-HDBK-5H (1998) Metallic materials and elements for aerospace vehicle structures. In: Knovel Interactive ed: U.S. Department of Defense

Akbulut H, Durman M, Yilmaz F (1998) High temperature Young’s modulus of alumina short fibre reinforced Al-Si MMCs produced by liquid infiltration. Mater Sci Tech-lond 14(4):299–305

Li WX (2005) Magnesium and magnesium alloys. Central South University Press, Changsha

Rudajevová A, Lukáč P (2005) Comparison of the thermal properties of AM20 and AS21 magnesium alloys. Mat Sci Eng A 397(1–2):16–21

Trojanová Z, Száraz Z, Palček P, Chalupová M (2011) Magnesium alloys based composites. In: Czerwinski F (ed) Magnesium alloys-design, processing and properties. InTech, Rijeka, pp 501–526

Zhang P (2005) Creep behavior of the die-cast Mg–Al alloy AS21. Scripta Mater 52(4):277–282

Counts WA, Friák M, Raabe D, Neugebauer J (2009) Using ab initio calculations in designing bcc Mg–Li alloys for ultra-lightweight applications. Acta Mater 57(1):69–76

Trojanová Z, Lukác P, Kainer KU, Gärtnerová V (2005) Dynamic strain ageing during stress relaxation in selected magnesium alloys containing rare earth elements. Adv Eng Mater 7(11):1027–1032

Lü Z, Zhou J, Sun ZM, Chen RS (2013) Effect of rare earth elements on the structures and mechanical properties of magnesium alloys. Chin Sci Bull 58(7):816–820

Tian WL, Qi LH, Zhou JM, Guan JT (2014) Effects of the fiber orientation and fiber aspect ratio on the tensile strength of Csf/Mg composites. Comp Mater Sci 89:6–11

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant Nos. 11672050, 11472066, 11727802 and 11602044, the Fundamental Research Funds for the Central Universities under Grant No. 106112017CDJQJ328840 and the Chongqing University Graduate Student Research Innovation Project under Grant No. CYS17016. We also thank the three anonymous reviewers for their helpful comments.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Shao, J., Li, W., Wang, R. et al. Temperature dependent compressive yield strength model for short fiber reinforced magnesium alloy matrix composites. J Mater Sci 53, 6065–6079 (2018). https://doi.org/10.1007/s10853-017-1980-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1980-y