Abstract

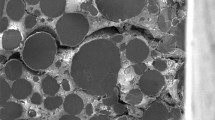

The in situ analysis of the damage evolution in a metal matrix composite (MMC) using synchrotron X-ray refraction radiography (SXRR) is presented. The investigated material is an Al alloy (6061)/10 vol\(\%\) \(\hbox {Al}_{2}\hbox {O}_{3}\) MMC after T6 heat treatment. In an interrupted tensile test the gauge section of dog bone-shaped specimens is imaged in different states of tensile loading. On the basis of the SXRR images, the relative change of the specific surface (proportional to the amount of damage) in the course of tensile loading was analyzed. It could be shown that the damage can be detected by SXRR already at a stage of tensile loading, in which no observation of damage is possible with radiographic absorption-based imaging methods. Moreover, the quantitative analysis of the SXRR images reveals that the amount of damage increases homogeneously by an average of 25% with respect to the initial state. To corroborate the experimental findings, the damage distribution was imaged in 3D after the final tensile loading by synchrotron X-ray refraction computed tomography (SXRCT) and absorption-based synchrotron X-ray computed tomography (SXCT). It could be evidenced that defects and damages cause pronounced indications in the SXRCT images.

Similar content being viewed by others

References

Mortensen A, Llorca J (2010) Metal matrix composites. Annu Rev Mater Res 40(1):243–270

Buffière JY, Proudhon H, Ferrie E, Ludwig W, Maire E, Cloetens P (2005) Three dimensional imaging of damage in structural materials using high resolution micro-tomography. Nucl Instrum Methods Phys Res B 238(1–4):75–82

Clyne TW, Withers PJ (1993) An introduction to metal matrix composites: Cambridge solid state science series. Cambridge University Press, Cambridge

Garces G, Bruno G, Wanner A (2007) Load transfer in short fibre reinforced metal matrix composites. Acta Mater 55(16):5389–5400

Garces G, Bruno G, Wanner A (2006) Residual stresses in random-planar aluminium/Saffil® short-fibre composites deformed in different loading modes. Int J Mater Res 97(10):1312–1319

Garces G, Bruno G, Wanner A (2006) Residual stresses in deformed random-planar aluminium/Saffil®short-fibre composites. Mater Sci Eng A 417(1–2):73–81

Garces G, Bruno G, Wanner A (2006) Internal stress evolution in a random-planar short fiber aluminum composite. Scr Mater 55(2):163–166

Cabeza S, Mishurova T, Bruno G, Garcés G, Requena G (2016) The role of reinforcement orientation on the damage evolution of AlSi12CuMgNi + 15% \(\text{Al}_2\text{O}_3\) under compression. Scr Mater 122:115–118

Requena G, Garcés G, Asghar Z, Marks E, Staron P, Cloetens P (2011) The effect of the connectivity of rigid phases on strength of Al–Si alloys. Adv Eng Mater 13(8):674–684

Requena G, Degischer H (2006) Creep behaviour of unreinforced and short fibre reinforced AlSi12CuMgNi piston alloy. Mater Sci Eng A 420(1–2):265–275

Requena GC, Degischer HP (2005) Effects of particle reinforcement on creep behaviour of AlSi1MgCu. Zeitschrift für Metallkunde 96(7):807–813

Russell SS, Sutton MA, Chen HS (1989) Image correlation quantitative NDE of impact and fabrication damage in a glass fiber reinforced composite system. J Mater Eval 47(5):550–558

Maire E, Withers PJ (2014) Quantitative X-ray tomography. Int Mater Rev 59(1):1–43

Stock SR (2009) Microcomputed tomography: methodology and applications. CRC Press, Boca Raton

Reimers W, Pyzalla AR, Schreyer A, Clemens H (2008) Neutrons and synchrotron radiation in engineering materials science. Wiley-VCH, Weinheim

Kriszt B, Foroughi B, Faure K, Degischer H (2000) Behaviour of aluminium foam under uniaxial compression. Mater Sci Technol 16:792–796

Babout L, Maire E, Buffière J, Fougères R (2001) Characterization by X-ray computed tomography of decohesion, porosity growth and coalescence in model matrix composites. Acta Mater 49:2055–2063

Ohgaki T, Toda H, Kobayashi M, Uesugi K, Niinomi M, Akahori T, Kobayash T, Makii K, Aruga Y (2006) In situ observations of compressive behaviour of aluminium foams by local tomography using high-resolution X-rays. Philos Mag 86(28):4417–4438

Khor KH, Buffière JY, Ludwig W, Toda H, Ubhi HS, Gregson PJ, Sinclair I (2004) In situ high resolution synchrotron X-ray tomography of fatigue crack closure micromechanisms. J Phys Condens Matter 16:3511–3515

Buffière JY, Maire E, Verdu C, Cloetens P, Pateyron M, Peix G, Baruchel J (1997) Damage assessment in an Al/SiC composite during monotonic tensile tests using synchrotron X-ray microtomography. Mater Sci Eng A A234–236:633–635

Adrien J, Maire E, Gimenez N, Sauvant-Moynot V (2007) Experimental study of the compression behaviour of syntactic foams by in situ X-ray tomography. Acta Mater 55(5):1667–1679

Ferrie E, Buffiere J, Ludwig W, Gravouil A, Edwards L (2006) Fatigue crack propagation: In situ visualization using X-ray microtomography and 3D simulation using the extended finite element method. Acta Mater 54:1111–1122

Borbély A, Biermann H, Hartmann O, Buffière J (2003) The influence of the free surface on the fracture of alumina particles in an Al–\(\text{Al}_2\text{O}_3\) metal-matrix composite. Comput Mater Sci 26:183–188

Borbély A, Csikor F, Zabler S, Cloetens P, Biermann H (2004) Three-dimensional characterization of the microstructure of a metal-matrix composite by holotomography. Mater Sci Eng A 367:40–50

Chapman D, Thomlinson W, Johnston RE, Washburn D, Pisano E, Gmür N, Zhong Z, Menk R, Arfelli F, Sayers D (1997) Diffraction enhanced x-ray imaging. Phys Med Biol 42:2015–2025

Müller BR, Hentschel MP (2013) Handbook of technical diagnostics, chap. Micro-diagnostics: x-ray and synchrotron techniques. Springer, Berlin, pp 287–300

de Andrade SF, Williams JJ, Müller BR, Hentschel MP, Portella PD, Chawla N (2010) Three-dimensional microstructure visualization of porosity and Fe-rich inclusions in SiC particle-reinforced al alloy matrix composites by x-ray synchrotron tomography. Metall Mater Trans A 41(8):2121–2128

Huppmann M, Camin B, Pyzalla AR, Reimers W (2010) In-situ observation of creep damage evolution in Al–\(\text{Al}_2\text{O}_3\) MMCs by synchrotron X-ray microtomography. Int J Mater Res 101(3):372–379

Soppa E, Fischer G, Seidenfuß M, Lammert R, Wackenhut G, Diem H (2008) Deformation and damage in Al based composites. FE simulations and experiments. In: Hirsch J, Skrotzki B, Gottstein G (eds) Aluminium alloys, their physical and mechanical properties, vol 2. Wiley-VCH, Weinheim, pp 1225–1231

Schneider Y, Soppa E, Kohler C, Mokso R, Roos E (2011) Numerical and experimental investigations of the global and local behaviour of an Al(6061)/\(\text{Al}_2\text{O}_3\) metal matrix composite under low cycle fatigue. Proced Eng 10:1515–1520; 11th international conference on the mechanical behavior of materials (ICM11)

Marrow T, Buffière JY, Withers P, Johnson G, Engelberg D (2004) High resolution X-ray tomography of short fatigue crack nucleation in austempered ductile cast iron. Int J Fatigue 26(7):717–725

Buffière JY, Maire E, Cloetens P, Lormand G, Fougères R (1999) Characterization of internal damage in a MMCp using X-ray synchrotron phase contrast microtomography. Acta Mater 47(5):1613–1625

Verdu C, Adrien J, Buffière J (2008) Three-dimensional shape of the early stages of fatigue cracks nucleated in nodular cast iron. Mater Sci Eng A 483–484:402–405

Babout L, Maire E, Fougères R (2004) Damage initiation in model metallic materials: X-ray tomography and modelling. Acta Mater 52(8):2475–2487

Maire E, Carmona V, Courbon J, Ludwig D (2007) Fast X-ray tomography and acoustic emission study of damage in metals during continuous tensile tests. Acta Mater 55:6806–6815

Buffière J, Maire E, Adrien J, Masse J, Boller E (2010) In situ experiments with X ray tomography: an attractive tool for experimental mechanics. Exp Mech 50:289–305

Görner W, Hentschel MP, Müller BR, Riesemeier H, Krumrey M, Ulm G, Diete W, Klein U, Frahm R (2001) BAMline: the first hard X-ray beamline at BESSY II. Nucl Instrum Methods Phys Res Sect A Accel Spectrom Detect Assoc Equip 467–468, Part 1:703–706; 7th international conference on synchrotron radiation instrumentation

Müller BR, Lange A, Hentschel MP, Kupsch A (2013) A comfortable procedure for correcting X-ray detector backlight. In: Journal of physics: conference series, vol. 425, No. 19, p. 192015

Hentschel MP, Kupsch A, Lange A, Müller BR (2013) Refraktions-interface-radiographie. DGZfP Jahrestagung 2013:1–12

Bruno G, Ehrig K, Haarring H, Harwardt M, Hentschel MP, Illerhaus B, Kupsch A, Lange A, Meinel D, Müller BR, Onel Y, Staude A, Wolk T (2014) Industrial and Synchrotron X-ray CT applications for materials characterisation. In: iCT conference 2014, pp 15–31

Laquai R, Müller BR, Kasperovich G, Haubrich J, Requena G, Bruno G (2018) X-ray refraction distinguishes unprocessed powder from empty pores in selective laser melting Ti-6Al-4V. Mater Res Lett 6(2):130–135

Fensch-Kleemann FE, Harbich KW, Hentschel MP (2002) Microstructural characterisation of porous ceramics by X-ray refraction topography. CFI Ceram Forum Int 79(11):E35–E38

Müller BR, Lange A, Harwardt M, Hentschel M, Illerhaus B, Goebbels J, Bamberg J, Heutling F (2004) Refraction computed tomography—application to metal matrix composites. MP Mater Test 46(6):314–319

Kak A, Slaney M (1988) Principles of computerized tomographic imaging. IEEE Press, Piscataway

Müller BR, Cooper R, Lange A, Kupsch A, Wheeler M, Hentschel M, Staude A, Pandey A, Shyam A, Bruno G (2018) Stress-induced microcrack density evolution in beta-eucryptite ceramics: experimental observations and possible route to strain hardening. Acta Mater 144(Supplement C):627–641

Harbich KW, Hentschel MP, Schors J (2001) X-ray refraction characterization of non-metallic materials. NDT & E Int 34(4):297–302

Hampe A, Harbich KW, Hentschel MP, Rudolph HV (1999) The determination of inner surfaces in composites by x-ray refraction. In: Proceedings of the ICCM-12 conference, Paris, France

Acknowledgements

We would like to express our gratitude to Wolfgang Czayka and Carsten Müller (both affiliated to the LWT/TU Dortmund University). Wolfgang Czayka prepared the specimens, and Carsten Müller engineered and modified the tensile test rig. For assistance during beamtime at the BAMline we would also like to thank Ralf Britzke and Thomas Wolk (BAM). Moreover, we thank HZB for the allocation of synchrotron radiation beamtime and thankfully acknowledge the financial support by HZB. The financial support of the German Research Foundation (DFG) in the frame of the projects TI 343/84-1 and SO 520/4-1 is gratefully acknowledged as well.

Author information

Authors and Affiliations

Corresponding author

Appendix: Derivation of equation (1)

Appendix: Derivation of equation (1)

The ratio of integrated experimental rocking curves yields the transmission, solely due to absorption:

Taking into account the additional reduction of intensity due to refraction, the ratio of the rocking curves’ peak intensity provides

where the refraction value \(C\) is an additional attenuation coefficient due to scattering. By dividing Eqs. (3) by (2), we obtain the refraction value \(C\) integrated along the ray path:

Conventional series expansion of the logarithm yields a reasonable first-order approximation:

Rights and permissions

About this article

Cite this article

Nellesen, J., Laquai, R., Müller, B.R. et al. In situ analysis of damage evolution in an Al/\(\hbox {Al}_{2}\hbox {O}_{3}\) MMC under tensile load by synchrotron X-ray refraction imaging. J Mater Sci 53, 6021–6032 (2018). https://doi.org/10.1007/s10853-017-1957-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1957-x