Abstract

Recent experimental and modeling studies in nanolayered metal/ceramic composites are reviewed, with focus on the mechanical behaviors of metal/nitrides interfaces. The experimental and modeling studies of the slip systems in bulk TiN are reviewed first. Then, the experimental studies of interfaces, including co-deformation mechanism by micropillar compression tests, in situ TEM straining tests for the dynamic process of the co-deformation, thickness-dependent fracture behavior, and interrelationship among the interfacial bonding, microstructure, and mechanical response, are reviewed for the specific material systems of Al/TiN and Cu/TiN multilayers at nanoscale. The modeling studies reviewed cover first-principles density functional theory-based modeling, atomistic molecular dynamics simulations, and mesoscale modeling of nanolayered composites using discrete dislocation dynamics. The phase transformation between zinc-blende and wurtzite AlN phases in Al/AlN multilayers at nanoscale is also reviewed. Finally, a summary and perspective of possible research directions and challenges are given.

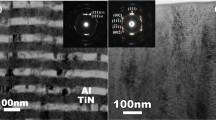

(Reproduced with permission from [52])

(Reproduced with permission from [52])

(Reproduced with permission from [9])

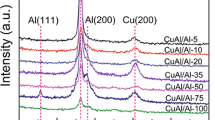

(Reproduced with permission from [10])

(Reproduced with permission from [10])

(Reproduced with permission from [95])

(Reproduced with permission from [96])

(Reproduced with permission from [97])

(Reproduced with permission from [72])

(Reproduced with permission from [72])

(Reproduced with permission from [69])

(Reproduced with permission from [85])

(Reproduced with permission from [85])

(Reproduced with permission from [86])

(Reproduced with permission from [53])

(Reproduced with permission from [53])

(Reproduced with permission from [54])

Similar content being viewed by others

References

Sinnott SB, Dickey EC (2003) Ceramic/metal interface structures and their relationship to atomic- and meso-scale properties. Mat Sci Eng R 43(1–2):1–59. https://doi.org/10.1016/J.Mser.2003.09.001

Padture NP, Gell M, Jordan EH (2002) Materials science—thermal barrier coatings for gas-turbine engine applications. Science 296(5566):280–284

Howe JM (1993) Bonding, structure, and properties of metal-ceramic interfaces. 1. Chemical bonding, chemical-reaction, and interfacial structure. Int Mater Rev 38(5):233–256

Finnis MW (1996) The theory of metal-ceramic interfaces. J Phys Condens Matter 8(32):5811–5836. https://doi.org/10.1088/0953-8984/8/32/003

Evans AG, Hutchinson JW, Wei Y (1999) Interface adhesion: effects of plasticity and segregation. Acta Mater 47(15–16):4093–4113. https://doi.org/10.1016/S1359-6454(99)00269-4

Zhang W, Smith JR (2000) Nonstoichiometric interfaces and Al2O3 adhesion with Al and Ag. Phys Rev Lett 85(15):3225–3228. https://doi.org/10.1103/Physrevlett.85.3225

Bhattacharyya D, Mara NA, Hoagland RG, Misra A (2008) Nanoindentation and microstructural studies of Al/TiN multilayers with unequal volume fractions. Scr Mater 58(11):981–984

Bhattacharyya D, Mara NA, Dickerson P, Hoagland RG, Misra A (2010) A transmission electron microscopy study of the deformation behavior underneath nanoindents in nanoscale Al-TiN multilayered composites. Philos Mag 90(13):1711–1724

Bhattacharyya D, Mara NA, Dickerson P, Hoagland RG, Misra A (2011) Compressive flow behavior of Al–TiN multilayers at nanometer scale layer thickness. Acta Mater 59(10):3804–3816

Li N, Wang H, Misra A, Wang J (2014) In situ nanoindentation study of plastic co-deformation in Al–TiN nanocomposites. Sci Rep-Uk 4:6633. https://doi.org/10.1038/Srep06633

Hoagland RG, Hirth JP, Misra A (2006) On the role of weak interfaces in blocking slip in nanoscale layered composites. Philos Mag 86(23):3537–3558. https://doi.org/10.1080/14786430600669790

Liu XY, Hoagland RG, Wang J, Germann TC, Misra A (2010) The influence of dilute heats of mixing on the atomic structures, defect energetics and mechanical properties of fcc-bcc interfaces. Acta Mater 58(13):4549–4557. https://doi.org/10.1016/j.actamat.2010.05.008

Wang J, Misra A, Hoagland RG, Hirth JP (2012) Slip transmission across fcc/bcc interfaces with varying interface shear strengths. Acta Mater 60(4):1503–1513. https://doi.org/10.1016/J.Actamat.2011.11.047

Wang J, Misra A (2014) Strain hardening in nanolayered thin films. Curr Opin Solid State M 18(1):19–28. https://doi.org/10.1016/J.Cossms.2013.10.003

Wang J, Zhou Q, Shao S, Misra A (2017) Strength and plasticity of nanolaminated materials. Mater Res Lett 5(1):1–19. https://doi.org/10.1080/21663831.2016.1225321

Abadias G, Dub S, Shmegera R (2006) Nanoindentation hardness and structure of ion beam sputtered TiN, W and TiN/W multilayer hard coatings. Surf Coat Technol 200(22):6538–6543. https://doi.org/10.1016/j.surfcoat.2005.11.053

Shih K, Dove D (1992) Ti/Ti–N Hf/Hf–N and W/W–N multilayer films with high mechanical hardness. Appl Phys Lett 61(6):654–656

He JL, Li WZ, Li HD, Liu CH (1998) Plastic properties of nano-scale ceramic–metal multilayers. Surf Coat Technol 103–104:276–280. https://doi.org/10.1016/S0257-8972(98)00423-X

Barnett SA, Madan A (2004) Hardness and stability of metal–nitride nanoscale multilayers. Scr Mater 50(6):739–744. https://doi.org/10.1016/j.scriptamat.2003.11.042

Abadias G, Pailloux F, Dub SN (2008) Epitaxial growth and mechanical properties of (001) ZrN/W nanolaminates. Surf Coat Technol 202(15):3683–3687. https://doi.org/10.1016/j.surfcoat.2008.01.013

Wen LS, Huang RF, Guo LP, Gong J, Wei TY, Chuang YZ (1993) Microstructure and mechanical properties of metal/ceramic Ti/TiN multilayers. J Magn Magn Mater 126(1):200–202. https://doi.org/10.1016/0304-8853(93)90580-U

Wang X, Kolitsch A, Möller W (1997) Roughness improvement and hardness enhancement in nanoscale Al/AlN multilayered thin films. Appl Phys Lett 71(14):1951–1953

Evans A, Rühle M (1990) Microstructure and fracture resistance of metal/ceramic interfaces. MRS Bull 15(10):46–50

Daia MB, Aubert P, Labdi S, Sant C, Sadi F, Houdy P, Bozet J-L (2000) Nanoindentation investigation of Ti/TiN multilayers films. J Appl Phys 87(11):7753–7757

Lackner JM, Waldhauser W, Major B, Major L, Kot M (2013) Plastic deformation in nano-scale multilayer materials—a biomimetic approach based on nacre. Thin Solid Films 534:417–425

Dück A, Gamer N, Gesatzke W, Griepentrog M, Österle W, Sahre M, Urban I (2001) Ti/TiN multilayer coatings: deposition technique, characterization and mechanical properties. Surf Coat Technol 142:579–584

Ma K, Bloyce A, Bell AT (1995) Examination of mechanical properties and failure mechanisms of TiN and Ti–TiN multilayer coatings. Surf Coat Technol 76:297–302

Madan A, Y-y Wang, Barnett S, Engström C, Ljungcrantz H, Hultman L, Grimsditch M (1998) Enhanced mechanical hardness in epitaxial nonisostructural Mo/NbN and W/NbN superlattices. J Appl Phys 84(2):776–785

Madan A, Barnett S, Misra A, Kung H, Nastasi M (2001) Structure, stability, and mechanical properties of epitaxial W/NbN superlattices. J Vac Sci Technol A Vac Surf Films 19(3):952–957

Abadias G, Michel A, Tromas C, Jaouen C, Dub SN (2007) Stress, interfacial effects and mechanical properties of nanoscale multilayered coatings. Surf Coat Technol 202(4):844–853. https://doi.org/10.1016/j.surfcoat.2007.05.068

Liu CH, Li W-Z, Li H-D (1995) Structure and hardness enhancement of Fe/TiC multilayered films. Nucl Instrum Methods Phys Res Sect B 95(3):323–326. https://doi.org/10.1016/0168-583X(94)00544-3

He J, Li W, Li H, Liu C (1998) Plastic properties of nano-scale ceramic–metal multilayers. Surf Coat Technol 103:276–280

Wang J, Li W-Z, Li H-D, Shi B, Luo J-B (2000) Nanoindentation study on the mechanical properties of Tic/Mo multilayers. Thin Solid Films 366(1):117–120. https://doi.org/10.1016/S0040-6090(99)00968-2

Wang X, Kolitsch A, Prokert F, Möller W (1998) Ion beam assisted deposition of AlN monolithic films and Al/AlN multilayers: a comparative study. Surf Coat Technol 103:334–339. https://doi.org/10.1016/S0257-8972(98)00410-1

Zhang GA, Wu ZG, Wang MX, Fan XY, Wang J, Yan PX (2007) Structure evolution and mechanical properties enhancement of Al/AlN multilayer. Appl Surf Sci 253(22):8835–8840. https://doi.org/10.1016/j.apsusc.2007.04.039

Koehler J (1970) Attempt to design a strong solid. Phys Rev B 2(2):547

Misra A, Hirth J, Hoagland R (2005) Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater 53(18):4817–4824

Shinn M, Hultman L, Barnett SA (2011) Growth, structure, and microhardness of epitaxial TiN/NbN superlattices. J Mater Res 7(4):901–911. https://doi.org/10.1557/JMR.1992.0901

Barnett SA, Madan A, Kim I, Martin K (2003) Stability of nanometer-thick layers in hard coatings. MRS Bull 28(3):169–172

Lotfian S, Rodríguez M, Yazzie K, Chawla N, Llorca J, Molina-Aldareguía JM (2013) High temperature micropillar compression of Al/SiC nanolaminates. Acta Mater 61(12):4439–4451

Sun P, Chu J, Lin T, Shen Y, Chawla N (2010) Characterization of nanoindentation damage in metal/ceramic multilayered films by transmission electron microscopy (TEM). Mater Sci Eng A 527(12):2985–2992

Zhang X, Zhang B, Mu Y, Shao S, Wick CD, Ramachandran BR, Meng WJ (2017) Mechanical failure of metal/ceramic interfacial regions under shear loading. Acta Mater 138:224–236. https://doi.org/10.1016/j.actamat.2017.07.053

Singh D, Chawla N, Tang G, Shen Y-L (2010) Micropillar compression of Al/SiC nanolaminates. Acta Mater 58(20):6628–6636

Singh DR, Chawla N (2012) Scratch resistance of Al/SiC metal/ceramic nanolaminates. J Mater Res 27(1):278–283

Lotfian S, Molina-Aldareguia JM, Yazzie K, Llorca J, Chawla N (2012) High-temperature nanoindentation behavior of Al/SiC multilayers. Philos Mag Lett 92(8):362–367

Lotfian S, Mayer C, Chawla N, Llorca J, Misra A, Baldwin J, Molina-Aldareguía JM (2014) Effect of layer thickness on the high temperature mechanical properties of Al/SiC nanolaminates. Thin Solid Films 571:260–267

Mayer C, Li N, Mara N, Chawla N (2015) Micromechanical and in situ shear testing of Al–SiC nanolaminate composites in a transmission electron microscope (TEM). Mater Sci Eng A 621:229–235

Mayer C, Yang L, Singh S, Xie H, Shen Y-L, Llorca J, Molina-Aldareguia J, Chawla N (2016) Orientation dependence of indentation behavior in Al–SiC nanolaminate composites. Mater Lett 168:129–133

Mayer C, Yang L, Singh S, Llorca J, Molina-Aldareguia J, Shen Y, Chawla N (2016) Anisotropy, size, and aspect ratio effects on micropillar compression of Al SiC nanolaminate composites. Acta Mater 114:25–32

Yang L, Mayer C, Chawla N, Llorca J, Molina-Aldareguía J (2016) Deformation mechanisms of ultra-thin Al layers in Al/SiC nanolaminates as a function of thickness and temperature. Philos Mag 96(32–34):3336–3355

Li N, Misra A, Shao S, Wang J (2015) Experimental quantification of resolved shear stresses for dislocation motion in TiN. Nano Lett 15(7):4434–4439. https://doi.org/10.1021/acs.nanolett.5b00791

Li N, Yadav SK, Liu XY, Wang J, Hoagland RG, Mara N, Misra A (2015) Quantification of dislocation nucleation stress in TiN through high-resolution in situ indentation experiments and first principles calculations. Sci Rep-Uk. https://doi.org/10.1038/Srep15813

Li N, Yadav SK, Wang J, Liu XY, Misra A (2015) Growth and Stress-induced Transformation of Zinc blende AlN Layers in Al–AlN–TiN Multilayers. Sci Rep-Uk 5:18554

Li Z, Yadav S, Chen Y, Li N, Liu X-Y, Wang J, Zhang S, Baldwin JK, Misra A, Mara N (2017) Mechanically controlling the reversible phase transformation from zinc blende to wurtzite in AlN. Mater Res Lett. https://doi.org/10.1080/21663831.2017.1303793

Hartford J (2000) Interface energy and electron structure for Fe/VN. Phys Rev B 61(3):2221–2229. https://doi.org/10.1103/Physrevb.61.2221

Dudiy SV, Lundqvist BI (2001) First-principles density-functional study of metal-carbonitride interface adhesion: Co/TiC(001) and Co/TiN(001). Phys Rev B 64(4):045403. https://doi.org/10.1103/Physrevb.64.045403

Siegel DJ, Hector LG, Adams JB (2002) First-principles study of metal-carbide/nitride adhesion: Al/VC vs Al/VN. Acta Mater 50(3):619–631

Liu LM, Wang SQ, Ye HQ (2003) Adhesion of metal-carbide/nitride interfaces: Al/TiC and Al/TiN. J Phys Condens Matter 15(47):8103–8114. https://doi.org/10.1088/0953-8984/15/47/013

Arya A, Carter EA (2003) Structure, bonding, and adhesion at the TiC(100)/Fe(110) interface from first principles. J Chem Phys 118(19):8982–8996. https://doi.org/10.1063/1.1565323

Siegel DJ, Hector LG, Adams JB (2003) Ab initio study of Al-ceramic interfacial adhesion. Phys Rev B. https://doi.org/10.1103/Physrevb.67.092105

Liu LM, Wang SQ, Ye HQ (2004) First-principles study of polar Al/TiN(111) interfaces. Acta Mater 52(12):3681–3688. https://doi.org/10.1016/J.Actamat.2004.04.022

Dudiy SV, Lundqvist BI (2004) Wetting of TiC and TiN by metals. Phys Rev B 69(12):125421. https://doi.org/10.1103/Physrevb.69.125421

Zhang HZ, Liu LM, Wang SQ (2007) First-principles study of the tensile and fracture of the Al/TiN interface. Comput Mater Sci 38(4):800–806. https://doi.org/10.1016/j.commatsci.2006.05.017

Bhattacharyya D, Liu XY, Genc A, Fraser HL, Hoagland RG, Misra A (2010) Heterotwin formation during growth of nanolayered Al–TiN composites. Appl Phys Lett 96(9):093113

Fors DHR, Wahnstrom G (2010) Theoretical study of interface structure and energetics in semicoherent Fe(001)/MX(001) systems (M = Sc, Ti, V, Cr, Zr, Nb, Hf, Ta; X = C or N). Phys Rev B 82(19):195410. https://doi.org/10.1103/Physrevb.82.195410

Yadav SK, Ramprasad R, Misra A, Liu XY (2012) First-principles study of shear behavior of Al, TiN, and coherent Al/TiN interfaces. J Appl Phys 111(8):083505

Sampath S, Janisch R (2013) Ab initio prediction of the critical thickness of a precipitate. J Phys Condens Matter. https://doi.org/10.1088/0953-8984/25/35/355005

Sawada H, Taniguchi S, Kawakami K, Ozaki T (2013) First-principles study of interface structure and energy of Fe/NbC. Model Simul Mater Sci Eng. https://doi.org/10.1088/0965-0393/21/4/045012

Yadav SK, Ramprasad R, Wang J, Misra A, Liu XY (2014) First-principles study of Cu/TiN and Al/TiN interfaces: weak versus strong interfaces. Model Simul Mater Sc 22(3):035020. https://doi.org/10.1088/0965-0393/22/3/035020

Fors DHR, Wahnstrom G (2011) First-principles investigation of the stability of MN and CrMN precipitates under coherency strains in α-Fe (M = V, Nb, Ta). J Appl Phys 109:113709

Wu X, Sun T, Wang R, Liu L, Liu Q (2014) Energy investigations on the adhesive properties of Al/TiC interfaces: first-principles study. Phys B 449:269–273. https://doi.org/10.1016/j.physb.2014.05.037

Yadav SK, Shao S, Wang J, Liu XY (2015) Structural modifications due to interface chemistry at metal-nitride interfaces. Sci Rep-Uk. https://doi.org/10.1038/Srep17380

Feldbauer G, Wolloch M, Bedolla P, Mohn P, Redinger J, Vernes A (2015) Adhesion and material transfer between contacting Al and TiN surfaces from first principles. Phys Rev B 91(16):165413

Yadav SK, Wang J, Liu XY (2016) Ab initio modeling of zincblende AlN layer in Al-AlN-TiN multilayers. J Appl Phys. https://doi.org/10.1063/1.4953593

Sun T, Wu XZ, Wang R, Li WG, Liu Q (2017) First-principles study on the adhesive properties of Al/TiC interfaces: revisited. Comput Mater Sci 126:108–120. https://doi.org/10.1016/j.commatsci.2016.09.024

Lin ZJ, Peng XH, Fu T, Zhao YB, Feng C, Huang C, Wang ZC (2017) Atomic structures and electronic properties of interfaces between aluminum and carbides/nitrides: a first-principles study. Phys E 89:15–20. https://doi.org/10.1016/j.physe.2017.01.025

Sawada H, Taniguchi S, Kawakami K, Ozaki T (2017) Transition of the interface between iron and carbide precipitate from coherent to semi-coherent. Metals. https://doi.org/10.3390/met7070277

Baskes MI (1992) Modified embedded-atom potentials for cubic materials and impurities. Phys Rev B 46(5):2727–2742. https://doi.org/10.1103/Physrevb.46.2727

Lee BJ, Baskes MI, Kim H, Cho YK (2001) Second nearest-neighbor modified embedded atom method potentials for bcc transition metals. Phys Rev B. https://doi.org/10.1103/Physrevb.64.184102

Daw MS, Baskes MI (1984) Embedded-atom method—derivation and application to impurities, surfaces, and other defects in metals. Phys Rev B 29(12):6443–6453. https://doi.org/10.1103/Physrevb.29.6443

Salehinia I, Shao S, Wang J, Zbib HM (2014) Plastic deformation of metal/ceramic nanolayered composites. Jom-Us 66(10):2078–2085. https://doi.org/10.1007/s11837-014-1132-7

Salehinia I, Wang J, Bahr DF, Zbib HM (2014) Molecular dynamics simulations of plastic deformation in Nb/NbC multilayers. Int J Plast 59:119–132. https://doi.org/10.1016/J.Ijplas.2014.03.010

Salehinia I, Shao S, Wang J, Zbib HM (2015) Interface structure and the inception of plasticity in Nb/NbC nanolayered composites. Acta Mater 86:331–340

Damadam M, Shao S, Salehinia I, Ayoub G, Zbib HM (2017) Molecular dynamics simulations of mechanical behavior in nanoscale ceramic-metallic multilayer composites. Mater Res Lett 5(5):306–313. https://doi.org/10.1080/21663831.2016.1275864

Yang W, Ayoub G, Salehinia I, Mansoor B, Zbib H (2017) Deformation mechanisms in Ti/TiN multilayer under compressive loading. Acta Mater 122:99–108. https://doi.org/10.1016/j.actamat.2016.09.039

Huang SX, Wang J, Zhou CZ (2015) Effect of plastic incompatibility on the strain hardening behavior of Al–TiN nanolayered composites. Mat Sci Eng A—Struct 636:430–433. https://doi.org/10.1016/j.msea.2015.04.013

Yadav SK, Liu XY, Wang J, Ramprasad R, Misra A, Hoagland RG (2013) First-principles density functional theory study of generalized stacking faults in TiN and MgO. Philos Mag 94(5):464–475. https://doi.org/10.1080/14786435.2013.856525

Yu H, Bahadori M, Thompson GB, Weinberger CR (2017) Understanding dislocation slip in stoichiometric rocksalt transition metal carbides and nitrides. J Mater Sci 52(11):6235–6248. https://doi.org/10.1007/s10853-017-0857-4

Yadav SK, Ramprasad R, Misra A, Liu XY (2014) Core structure and Peierls stress of edge and screw dislocations in TiN: a density functional theory study. Acta Mater 74:268–277

Cai W, Bulatov VV, Chang JP, Li J, Yip S (2001) Anisotropic elastic interactions of a periodic dislocation array. Phys Rev Lett 86(25):5727–5730

Cai W, Bulatov VV, Chang JP, Li J, Yip S (2003) Periodic image effects in dislocation modelling. Philos Mag 83(5):539–567

Romaner L, Ambrosch-Draxl C, Pippan R (2010) Effect of rhenium on the dislocation core structure in tungsten. Phys Rev Lett. https://doi.org/10.1103/Physrevlett.104.195503

Mara NA, Li N, Misra A, Wang J (2016) Interface-driven plasticity in metal-ceramic nanolayered composites: direct validation of multiscale deformation modeling via in situ indentation in TEM. Jom-Us 68(1):143–150

Han SM, Phillips MA, Nix WD (2009) Study of strain softening behavior of Al–Al3Sc multilayers using microcompression testing. Acta Mater 57(15):4473–4490. https://doi.org/10.1016/j.actamat.2009.06.007

Mook WM, Raghavan R, Baldwin JK, Frey D, Michler J, Mara NA, Misra A (2013) Indentation fracture response of Al–TiN nanolaminates. Mater Res Lett 1(2):102–108

Pathak S, Li N, Maeder X, Hoagland RG, Baldwin JK, Michler J, Misra A, Wang J, Mara NA (2015) On the origins of hardness of Cu–TiN nanolayered composites. Scr Mater 109:48–51. https://doi.org/10.1016/j.scriptamat.2015.07.015

Liu LM, Wang SQ, Ye HQ (2005) First-principles study of the effect of hydrogen on the metal-ceramic interface. J Phys Condens Matter 17(35):5335–5348. https://doi.org/10.1088/0953-8984/17/35/002

Zhu H, Tang C, Ramprasad R (2010) Phase equilibria at Si–HfO2 and Pt–HfO2 interfaces from first principles thermodynamics. Phys Rev B. https://doi.org/10.1103/Physrevb.82.235413

Touloukian YS, Kirby RK, Taylor RE, Desai PD (1975) Thermal expansion metallic elements and alloys. IFI/Plenum, New York

Schonberg N (1954) An X-ray study of the tantalum–nitrogen system. Acta Chem Scand 8(2):199–203

Liu ZQ, Wang WJ, Wang TM, Chao S, Zheng SK (1998) Thermal stability of copper nitride films prepared by rf magnetron sputtering. Thin Solid Films 325(1–2):55–59. https://doi.org/10.1016/S0040-6090(98)00448-9

Maruyama T, Morishita T (1996) Copper nitride and tin nitride thin films for write-once optical recording media. Appl Phys Lett 69(7):890–891. https://doi.org/10.1063/1.117978

Kittle C (1996) Introduction to solid state physics. Wiley, New York

Abe K, Harada Y, Onoda H (1997) Cu crystallographic texture control in Cu/refractory-metal layered structure as interconnects. Appl Phys Lett 71(19):2782–2784. https://doi.org/10.1063/1.120132

Damadam M, Shao S, Salehinia I, Mastorakos I, Ayoub G, Zbib HM (2017) Strength and plastic deformation behavior of nanolaminate composites with pre-existing dislocations. Comput Mater Sci 138:42–48. https://doi.org/10.1016/j.commatsci.2017.06.016

Liang T, Ashton M, Choudhary K, Zhang DF, Fonseca AF, Revard BC, Hennig RG, Phillpot SR, Sinnott SB (2016) Properties of Ti/TiC interfaces from molecular dynamics simulations. J Phys Chem C 120(23):12530–12538

Wang J, Li N, Anderoglu O, Zhang X, Misra A, Huang J, Hirth J (2010) Detwinning mechanisms for growth twins in face-centered cubic metals. Acta Mater 58(6):2262–2270

Moya JS, Lopez-Esteban S, Pecharroman C (2007) The challenge of ceramic/metal microcomposites and nanocomposites. Prog Mater Sci 52(7):1017–1090

Ernst F (1995) Metal-oxide interfaces. Mater Sci Eng R: Rep 14(3):97–156

Botu V, Ramprasad R (2015) Adaptive machine learning framework to accelerate ab initio molecular dynamics. Int J Quantum Chem 115(16):1074–1083. https://doi.org/10.1002/qua.24836

Perez D, Uberuaga BP, Voter AF (2015) The parallel replica dynamics method—coming of age. Comput Mater Sci 100:90–103. https://doi.org/10.1016/j.commatsci.2014.12.011

Acknowledgements

This work was supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences. The authors acknowledge collaborations with A. Misra, R.G. Hoagland, J.P. Hirth, J. Wang, N. Mara, D. Bhattacharyya, W.M. Mook, S.K. Yadav, S. Shao, Y. Chen. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the US Department of Energy Office of Science. Los Alamos National Laboratory is operated by Los Alamos National Security, LLC, for the National Nuclear Security Administration of the US Department of Energy under Contract No. DE-AC52-06NA25396.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, N., Liu, XY. Review: mechanical behavior of metal/ceramic interfaces in nanolayered composites—experiments and modeling. J Mater Sci 53, 5562–5583 (2018). https://doi.org/10.1007/s10853-017-1767-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1767-1