Abstract

The deformation response of random grain boundary networks as a function of temperature and strain rate is explored using molecular dynamics atomistic simulations and an embedded atom method interatomic potential. We find that deformation at higher temperatures promotes both dislocation emission and grain boundary accommodation processes. The results allow estimating the activation energies and volumes for the deformation process. We find activation energy values for the deformation process similar to those for grain boundary diffusion and activation volumes consistent with an atomic shuffling mechanism. Our results suggest a picture of the deformation process as governed by the combination of the applied stress and thermally activated processes.

Similar content being viewed by others

References

Arzt E (1998) Size effects in materials due to microstructural and dimensional constraints: a comparative review. Acta Mater 46:5611–5626

Ma E (2006) Eight routes to improve the tensile ductility of bulk nanostructured metals and alloys. JOM 58:49–53

Mara NA, Bhattacharyya D, Hoagland RG, Misra A (2008) Tensile behavior of 40 nm Cu/Nb nanoscale multilayers. Scr Mater 58:874–877

Beyerlein IJ, Mara NA, Bhattacharyya D, Alexander DJ, Necker CT (2011) Texture evolution via combined slip and deformation twinning in rolled silver–copper cast eutectic nanocomposite. Int J Plast 27:121–146

Sangid MD, Ezaz T, Sehitoglu H, Robertson IM (2011) Energy of slip transmission and nucleation at grain boundaries. Acta Mater 59:283–296

Van Swygenhoven H, Farkas D, Caro A (2000) Grain-boundary structures in polycrystalline metals at the nanoscale. Phys Rev B 62:831–838

Tschopp MA, McDowell DL (2007) Asymmetric tilt grain boundary structure and energy in copper and aluminium. Philos Mag 87:3871–3892

Chen MW, Ma E, Hemker KJ, Sheng HW, Wang YM, Cheng XM (2003) Deformation twinning in nanocrystalline aluminum. Science 300:1275–1277

Farkas D, Patrick L (2009) Tensile deformation of fcc Ni as described by an EAM potential. Philos Mag 89:3435–3450

Jeon JB, Lee B-J, Chang YW (2011) Molecular dynamics simulation study of the effect of grain size on the deformation behavior of nanocrystalline body-centered cubic iron. Scr Mater 64:494–497

McMurtrey MD, Was GS, Patrick L, Farkas D (2011) Relationship between localized strain and irradiation assisted stress corrosion cracking in an austenitic alloy. Mater Sci Eng Struct Mater Prop Microstruct Process 528:3730–3740

Stukowski A, Albe K, Farkas D (2010) Nanotwinned fcc metals: strengthening versus softening mechanisms. Phys Rev B 82:224103

Vo NQ, Averback RS, Bellon P, Caro A (2009) Yield strength in nanocrystalline Cu during high strain rate deformation. Scr Mater 61:76–79

Asaro RJ, Suresh S (2005) Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater 53:3369–3382

Lee TC, Robertson IM, Birnbaum HK (1989) Prediction of slip transfer mechanisms across grain boundaries. Scr Metall 23:799–803

Lee TC, Robertson IM, Birnbaum HK (1990) TEM in situ deformation study of the interaction of lattice dislocations with grain boundaries in metals. Philos Mag A 62:131–153

Lee TC, Robertson IM, Birnbaum HK (1990) In situ transmission electron microscope deformation study of the slip transfer mechanisms in metals. Metall Trans A (Phys Metall Mater Sci) 21A:2437–2447

Clark WAT, Wagoner RH, Shen ZY, Lee TC, Robertson IM, Birnbaum HK (1992) On the criteria for slip transmission across interfaces in polycrystals. Scr Metall Mater. 26:203–206

Suri S, Viswanathan GB, Neeraj T, Hou DH, Mills MJ (1999) Room temperature deformation and mechanisms of slip transmission in oriented single-colony crystals of an α/β titanium alloy. Acta Mater 47:1019–1034

Dingley DJ, Pond RC (1979) Interaction of crystal dislocations with grain-boundaries. Acta Metall 27:667–682

de Koning M, Miller R, Bulatov VV, Abraham FF (2002) Modelling grain-boundary resistance in intergranular dislocation slip transmission. Philos Mag A-Phys Condens Matter Struct Defect Mech Prop 82:2511–2527

Jin ZH, Gumbsch P, Albe K et al (2008) Interactions between non-screw lattice dislocations and coherent twin boundaries in face-centered cubic metals. Acta Mater 56:1126–1135

Kelchner CL, Plimpton SJ, Hamilton JC (1998) Dislocation nucleation and defect structure during surface indentation. Phys Rev B 58:11085–11088

Kumar R, Szekely F, Van der Giessen E (2010) Modelling dislocation transmission across tilt grain boundaries in 2D. Comput Mater Sci 49:46–54

Smith L, Farkas D (2013) Non-planar grain boundary structures in fcc metals and their role in nano-scale deformation mechanisms. Philos Mag 94:152–173

Smith L, Farkas D (2014) Non-planar grain boundary structures in fcc metals and their role in nano-scale deformation mechanisms. Philos Mag 94:152–173

Smith L, Zimmerman JA, Hale LM, Farkas D (2014) Molecular dynamics study of deformation and fracture in a tantalum nano-crystalline thin film. Model Simul Mater Sci Eng 22:045010. https://doi.org/10.1088/0965-0393/22/4/045010

Tucker GJ, Tschopp MA, McDowell DL (2010) Evolution of structure and free volume in symmetric tilt grain boundaries during dislocation nucleation. Acta Mater 58:6464–6473

Du JP, Wang YJ, Lo YC, Wan L, Ogata S (2016) Mechanism transition and strong temperature dependence of dislocation nucleation from grain boundaries: an accelerated molecular dynamics study. Phys Rev B 94:104110

Jiao SY, Kulkarni Y (2015) Molecular dynamics study of creep mechanisms in nanotwinned metals. Comput Mater Sci 110:254–260

Nie K, Wu WP, Zhang XL, Yang SM (2017) Molecular dynamics study on the grain size, temperature, and stress dependence of creep behavior in nanocrystalline nickel. J Mater Sci 52:2180–2191 https://doi.org/10.1007/s10853-016-0506-3

Van Swygenhoven H, Derlet PM, Hasnaoui A (2002) Atomic mechanism for dislocation emission from nanosized grain boundaries. Phys Rev B 66:024101. https://doi.org/10.1103/PhysRevB.66.024101

Spearot DE, McDowell DL (2009) Atomistic modeling of grain boundaries and dislocation processes in metallic polycrystalline materials. J Eng Mater Technol-Trans ASME 131:041204

Farkas D, Curtin WA (2005) Plastic deformation mechanisms in nanocrystalline columnar grain structures. Mater Sci Eng A-Struct Mater Prop Microstruct Process 412:316–322

Smith L, Farkas D (2013) Non-planar grain boundary structures in fcc metals and their role in nano-scale deformation mechanisms. Philos Mag 94:152–173

Van Swygenhoven H, Spaczer M, Caro A, Farkas D (1999) Competing plastic deformation mechanisms in nanophase metals. Phys Rev B 60:22–25

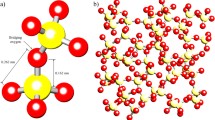

Mishin Y, Farkas D, Mehl MJ, Papaconstantopoulos DA (1999) Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys Rev B 59:3393–3407

Wolf D, Yip S (1992) Materials interfaces: atomic-level structure and properties. Springer, Berlin

Plimpton S (1995) Fast parallel algorithms for short-range molecular-dynamics. J Comput Phys 117:1–19

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO—the Open Visualization Tool. Model Simul Mater Sci Eng 18:015012

Holm EA, Olmsted DL, Foiles SM (2010) Comparing grain boundary energies in face-centered cubic metals: Al, Au, Cu and Ni. Scr Mater 63:905–908

Rohrer GS, Holm EA, Rollett AD, Foiles SM, Li J, Olmsted DL (2010) Comparing calculated and measured grain boundary energies in nickel. Acta Mater 58:5063–5069

Olmsted DL, Foiles SM, Holm EA (2009) Survey of computed grain boundary properties in face-centered cubic metals: I. Grain boundary energy. Acta Mater 57:3694–3703

Olmsted DL, Holm EA, Foiles SM (2009) Survey of computed grain boundary properties in face-centered cubic metals-II: grain boundary mobility. Acta Mater 57:3704–3713

Luo J, Li MQ, Yu WX, Li H (2010) The variation of strain rate sensitivity exponent and strain hardening exponent in isothermal compression of Ti-6Al-4V alloy. Mater Des 31:741–748

Picu RC, Vincze G, Ozturk F, Gracio JJ, Barlat F, Maniatty AM (2005) Strain rate sensitivity of the commercial aluminum alloy AA5182-O. Mater Sci Eng A-Struct Mater Prop Microstruct Process 390:334–343

Romhanji E, Dudukovska A, Glisic D (2002) The effect of temperature on strain-rate sensitivity in high strength Al–Mg alloy sheet. J Mater Process Technol 125:193–198

Deng C, Sansoz F (2010) Effects of twin and surface facet on strain-rate sensitivity of gold nanowires at different temperatures. Phys Rev B 81:7. https://doi.org/10.1103/PhysRevB.81.155430

Monk J, Farkas D (2007) Strain-induced grain growth and rotation in nickel nanowires. Phys Rev B 75:5. https://doi.org/10.1103/PhysRevB.75.045414

Kocks UF, Argon AS, Ashby MF (1975) Thermodynamics and kinetics of slip. Prog Mater Sci 19:1–291

Bokstein BS, Brose HD, Trusov LI, Khvostantseva TP (1995) Diffusion in nanocrystalline nickel. Nanostruct Mater 6:873–876

Prokoshkina D, Esin VA, Wilde G, Divinski SV (2013) Grain boundary width, energy and self-diffusion in nickel: effect of material purity. Acta Mater 61:5188–5197

Frolov T, Olmsted DL, Asta M, Mishin Y (2013) Structural phase transformations in metallic grain boundaries. Nat Commun 4:1899. https://doi.org/10.1038/ncomms2919

Karma A, Trautt ZT, Mishin Y (2012) Relationship between equilibrium fluctuations and shear-coupled motion of grain boundaries. Phys Rev Lett 109:095501

Frolov T, Asta M, Mishin Y (2016) Phase transformations at interfaces: observations from atomistic modeling. Curr Opin Solid State Mater Sci 20:308–315

Fensin SJ, Asta M, Hoagland RG (2012) Temperature dependence of the structure and shear response of a Sigma 11 asymmetric tilt grain boundary in copper from molecular-dynamics. Philos Mag 92:4320–4333

Acknowledgements

This work was supported by the Department of Energy, Office of Basic Energy Sciences, under Grant DE-FG02-08ER46525. Critical discussions with Ian Robertson, (University of Wisconsin) and Josh Kacher (Georgia Tech) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Smith, L., Farkas, D. Deformation response of grain boundary networks at high temperature. J Mater Sci 53, 5696–5705 (2018). https://doi.org/10.1007/s10853-017-1760-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1760-8