Abstract

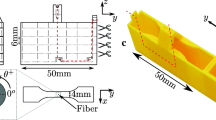

To visualize the debonding event in real time for the study of dynamic crack initiation and propagation at the fiber–matrix interface, a modified tension Kolsky bar was integrated with a high-speed synchrotron X-ray phase-contrast imaging setup. In the gage section, the pull-out configuration was utilized to understand the behavior of interfacial debonding between SC-15 epoxy matrix and S-2 glass fiber, tungsten wire, steel wire, and carbon fiber composite Z-pin at pull-out velocities of 2.5 and 5.0 m s−1. The load history and images of the debonding progression were simultaneously recorded. Both S-2 glass fiber and Z-pin experienced catastrophic interfacial debonding whereas tungsten and steel wire experienced both catastrophic debonding and stick–slip behavior. Even though S-2 glass fiber and Z-pin samples exhibited a slight increase and tungsten and steel wire samples exhibited a slight decrease in average peak force and average interfacial shear stress as the pull-out velocities were increased, no statistical difference was found for most properties when the velocity was increased. Furthermore, the debonding behavior for each fiber material is similar with increasing pull-out velocity. Thus, the debonding mechanism, peak force, and interfacial shear stress were rate insensitive as the pull-out velocity doubled from 2.5 to 5.0 m s−1. Scanning electron microscope imaging of recovered epoxy beads revealed a snap-back behavior around the meniscus region of the bead for S-2 glass, tungsten, and steel fiber materials at 5.0 m s−1 whereas those at 2.5 m s−1 exhibited no snap-back behavior.

Similar content being viewed by others

References

Broutman LJ (1969) Measurement of the fiber-polymer matrix interfacial strength. In: Committee D (ed) STP44698S Interfaces in composites, STP44698S. ASTM International, West Conshohocken, PA, pp 27–41

Mandell JF, Chen JF, McGarry FH (1980) A microdebonding test for in situ fiber-matrix bond strength and moisture effects (No. MIT/RR-R80-1). Massachusetts Inst of Tech Cambridge Dept of Materials Science and Engineering

Miller B, Muri P, Rebenfeld L (1987) A microbond method for determination of the shear strength of a fiber/resin interface. Compos Sci Technol 28(1):17–32

Kelly A, Tyson WR (1965) Tensile properties of fibre-reinforced metals: copper/tungsten and copper/molybdenum. J Mech Phys Solids 13(6):329–350

Gao X (2006) Tailored interphase structure for improved strength and energy absorption of composites. Dissertation, University of Delaware

Herrera-Franco PJ, Drzal LT (1992) Comparison of methods for the measurement of fibre/matrix adhesion in composites. Composites 23(1):2–27

Yang L, Thomason JL (2010) Interface strength in glass fibre-polypropylene measured using the fibre pull-out and microbond methods. Compos A Appl Sci Manuf 41(9):1077–1083

Hudspeth M, Claus B, Dubelman S, Black J, Mondal A, Parab N, Funnell C, Hai F, Qi ML, Fezzaa K, Luo SN (2013) High speed synchrotron X-ray phase contrast imaging of dynamic material response to split Hopkinson bar loading. Rev Sci Instrum 84(2):025102

Tamrakar S, Haque BZ, Gillespie JW (2016) High rate test method for fiber-matrix interface characterization. Polym Test 52:174–183

Li Z, Bi X, Lambros J, Geubelle PH (2002) Dynamic fiber debonding and frictional push-out in mode composite systems: experimental observations. Exp Mech 42(4):417–425

Tanoglu M, McKnight SH, Palmese GR, Gillespie JW Jr (2001) The effects of glass-fiber sizings on the strength and energy absorption of the fiber/matrix interphase under high loading rates. Compos Sci Technol 61(2):205–220

Tanoglu M, McKnight SH, Palmese GR, Gillespie JW (2000) A new technique to characterize the fiber/matrix interphase properties under high strain rates. Compos A Appl Sci Manuf 31(10):1127–1138

Greenfield MJ, Pedicini A, Penn LS (2000) Development of a single fiber fragmentation test for high strain rates. Int J Adhes Adhes 5:403–407

Parab ND, Guo Z, Hudspeth M, Claus B, Lim BH, Sun T, Xiao X, Fezzaa K, Chen WW (2017) In situ observation of fracture processes in high-strength concretes and limestone using high-speed X-ray phase-contrast imaging. Philos Trans R Soc A 375(2085):20160178

Dransfield K, Baillie C, Mai YW (1994) Improving the delamination resistance of CFRP by stitching—a review. Compos Sci Technol 50(3):305–317

Ashton T, Negre P, Langer J (2001) Interlaminar damage resistance of Z fiberTM reinforced structural CFRP. In: Extended abstracts of the 13th international conference on composite materials

Parab ND, Roberts ZA, Harr MH, Mares JO, Casey AD, Gunduz IE, Hudspeth M, Claus B, Sun T, Fezzaa K, Son SF (2016) High speed X-ray phase contrast imaging of energetic composites under dynamic compression. Appl Phys Lett 109(13):131903

Levine S, Nie Y, Chen W (2016) Dynamic transverse debonding of a single fiber. J Dyn Behav Mater 2(4):521–531

Hudspeth M, Claus B, Parab N, Lim B, Chen W, Sun T, Fezza K (2015) In situ visual observation of fracture processes in several high-performance fibers. J Dyn Behav Mater 1(1):55–64

Parab ND, Black JT, Claus B, Hudspeth M, Sun J, Fezzaa K, Chen WW (2014) Observation of crack propagation in glass using X-ray phase contrast imaging. Int J Appl Glass Sci 5(4):363–373

Parab ND, Claus B, Hudspeth MC, Black JT, Mondal A, Sun J, Fezzaa K, Xiao X, Luo SN, Chen W (2014) Experimental assessment of fracture of individual sand particles at different loading rates. Int J Impact Eng 68:8–14

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH image to ImageJ: 25 years of image analysis. Nat Methods 9(7):671–675

Carroll BJ (1986) Equilibrium conformations of liquid drops on thin cylinders under forces of capillarity. A theory for the roll-up process. Langmuir 2(2):248–250

Miller B, Gaur U, Hirt DE (1991) Measurement and mechanical aspects of the microbond pull-out technique for obtaining fiber/resin interfacial shear strength. Compos Sci Technol 42(1–3):207–219

Gaur U, Miller B (1989) Microbond method for determination of the shear strength of a fiber/resin interface: evaluation of experimental parameters. Compos Sci Technol 34(1):35–51

Cen H, Kang Y, Lei Z, Qin Q, Qiu W (2006) Micromechanics analysis of Kevlar-29 aramid fiber and epoxy resin microdroplet composite by Micro-Raman spectroscopy. Compos Struct 75(1):532–538

Zhi C, Long H, Miao M (2017) Influence of microbond test parameters on interfacial shear strength of fiber reinforced polymer-matrix composites. Compos A Appl Sci Manuf 100:55–63

Takaku A, Arridge RG (1973) The effect of interfacial radial and shear stress on fibre pull-out in composite materials. J Phys D Appl Phys 6(17):2038

Acknowledgements

This research was partially sponsored by the Army Research Laboratory and was accomplished under Cooperative Agreement Number W911NF-12-2-0022. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the US Government. The US Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein. The authors thank insightful discussions with University of Delaware researchers. The authors also thank Brady Aydelotte from Army Research Laboratory for his insightful and professional input in this research. Lastly, the authors thank Alex Deriy from Argonne National Laboratory’s APS for his professional help during our beam time. This research used resources of the Advanced Photon Source, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in this article.

Rights and permissions

About this article

Cite this article

Chu, JM., Claus, B., Parab, N. et al. Visualization of dynamic fiber-matrix interfacial shear debonding. J Mater Sci 53, 5845–5859 (2018). https://doi.org/10.1007/s10853-017-1759-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1759-1