Abstract

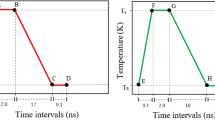

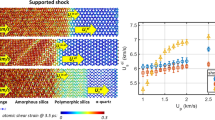

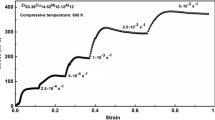

The shock response of Cu x Zr100−x (x = 30, 50 and 70) metallic glasses (MGs) is characterized using large-scale molecular dynamics simulations. A wide range of piston velocities U p = 0.125–2.5 km/s are simulated corresponding to shock pressures from 3 to 130 GPa. Independent of composition, the metallic glasses exhibit the following shock wave propagation regimes: (1) single elastic shock wave for U p < 0.25 km/s, (2) split elastic and plastic shock waves for 0.25 < U p < 0.75 km/s and (3) overdriven plastic shock wave with a narrow elastic precursor for U p > 0.75 km/s. Within the split wave and overdriven regimes, the amplitude of the elastic precursor increases with increasing shock intensity, thereby indicating a pressure-dependent yield criterion. Hugoniot states are strongly dependent on the Cu content of the MG with Cu70Zr30 exhibiting a much higher resistance to plastic deformation than either Cu50Zr50 or Cu30Zr70.

Similar content being viewed by others

References

Schuh CA, Hufnagel TC, Ramamurty U (2007) Mechanical behavior of amorphous alloys. Acta Mater 55(12):4067–4109

Inoue A, Takeuchi A (2011) Recent development and application products of bulk glassy alloys. Acta Mater 59(6):2243–2267

Cheng YQ, Ma E (2011) Atomic-level structure and structure–property relationship in metallic glasses. Prog Mater Sci 56(4):379–473

Wang WH (2012) The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog Mater Sci 57(3):487–656

Hufnagel TC, Schuh CA, Falk ML (2016) Deformation of metallic glasses: recent developments in theory, simulations, and experiments. Acta Mater 109:375–393

Mashimo T, Togo H, Zhang Y, Uemura Y, Kinoshita T, Kodama M, Kawamura Y (2006) Hugoniot-compression curve of Zr-based bulk metallic glass. Appl Phys Lett 89(24):31–33

Turneaure SJ, Winey JM, Gupta YM (2006) Response of a Zr-based bulk amorphous alloy to shock wave compression. J Appl Phys 100(6):063522–063532

Martin M, Sekine T, Kobayashi T, Kecskes L, Thadhani NN (2007) High-pressure equation of the state of a zirconium-based bulk metallic glass. Metall Mater Trans A 38(11):2689–2696

Xi F, Yu Y, Dai C, Zhang Y, Cai L (2010) Shock compression response of a Zr-based bulk metallic glass up to 110 GPa. J Appl Phys 108(8):1–5

Luo B, Wang G, Tan F, Zhao J, Liu C, Sun C (2015) Dynamic behaviors of a Zr-based bulk metallic glass under ramp wave and shock wave loading. AIP Adv 5(6):067161–067169

Yu Y-Y, Xi F, Dai C-D, Cai L-C, Tan Y, Li X-M, Wu Q, Tan H (2015) Dynamic strength behavior of a Zr-based bulk metallic glass under shock loading. Chin Phys B 24(6):066201–066206

Huang X, Ling Z, Zhang HS, Ma J, Dai LH (2011) How does spallation microdamage nucleate in bulk amorphous alloys under shock loading. J Appl Phys 110:103519–103528

Lu L, Li C, Wang WH, Zhu MH, Gong XL, Luo SN (2016) Ductile fracture of bulk metallic glass Zr50Cu40Al10 under high strain-rate loading. Mater Sci Eng A 651:848–853

Jarmakani HN, Bringa EM, Erhart P, Remington BA, Wang YM, Vo NQ, Meyers MA (2008) Molecular dynamics simulations of shock compression of nickel: from monocrystals to nanocrystals. Acta Mater 56(19):5584–5604

Cao B, Bringa EM, Meyers MA (2007) Shock compression of monocrystalline copper: atomistic simulations. Metall Mater Trans A 38(11):2681–2688

Bringa EM, Cazamias JU, Erhart P, Stölken J, Tanushev N, Wirth BD, Rudd RE, Caturla MJ (2004) Atomistic shock Hugoniot simulation of single-crystal copper. J Appl Phys 96(7):3793–3799

Bringa EM, Rosolankova K, Rudd RE, Remington BA, Wark JS, Duchaineau M, Kalantar DH, Hawreliak J, Belak J (2006) Shock deformation of face-centred-cubic metals on subnanosecond timescales. Nat Mater 5(10):805–809

Wen P, Tao G, Pang C, Yuan S, Wang Q (2016) A molecular dynamics study of the shock-induced defect microstructure in single crystal Cu. Comput Mater Sci 124:304–310

Sichani MM, Spearot DE (2016) A molecular dynamics study of dislocation density generation and plastic relaxation during shock of single crystal Cu. J Appl Phys 120:045902–045911

Ravelo R, Germann TC, Guerrero O, An Q, Holian BL (2013) Shock-induced plasticity in tantalum single crystals: interatomic potentials and large-scale molecular-dynamics simulations. Phys Rev B Condens Matter Mater Phys 88(13):134101–134118

Zhakhovsky VV, Budzevich MM, Inogamov NA, Oleynik II, White CT (2011) Two-zone elastic-plastic single shock waves in solids. Phys Rev Lett 107(September):1–4

Kadau K, Germann TC, Lomdahl PS, Holian BL (2005) Atomistic simulations of shock-induced transformations and their orientation dependence in bcc Fe single crystals. Phys Rev B Condens Matter Mater Phys 72(6):1–14

Tramontina D, Erhart P, Germann T, Hawreliak J, Higginbotham A, Park N, Ravelo R, Stukowski A, Suggit M, Tang Y, Wark J, Bringa E (2014) Molecular dynamics simulations of shock-induced plasticity in tantalum. High Energy Density Phys 10:9–15

Sichani MM, Spearot DE (2016) A molecular dynamics study of the role of grain size and orientation on compression of nanocrystalline Cu during shock. Comput Mater Sci J 108:226–232

Bringa EM, Caro A, Wang Y, Victoria M, McNaney JM, Remington BA, Smith RF, Torralva BR, Van Swygenhoven H (2005) Ultrahigh strength in nanocrystalline materials under shock loading. Science 309(5742):1838–1841

Ma W, Zhu W, Hou Y (2013) A comparative study on shock compression of nanocrystalline Al and Cu: shock profiles and microscopic views of plasticity. J Appl Phys 114(16):1–9

Ma W, Zhu W, Fuqian J (2010) The shock-front structure of nanocrystalline aluminum. Appl Phys Lett 97(12):121903–121905

Jian WR, Yao XH, Wang L, Tang XC, Luo SN (2015) Short- and medium-range orders in Cu46Zr54 metallic glasses under shock compression. J Appl Phys 118(1):15901–15909

Arman B, Luo SN, Germann TC, ÇaǧIn T (2010) Dynamic response of Cu46Zr54 metallic glass to high-strain-rate shock loading: Plasticity, spall, and atomic-level structures. Phys Rev B Condens Matter Mater Phys 81:1–12

Marinier S, Lewis LJ (2015) Femtosecond laser ablation of Cu x Zr1−x bulk metallic glasses: a molecular dynamics study. Phys Rev B 92(18):184108–184116

Huang X, Ling Z, Dai LH (2014) Ductile-to-brittle transition in spallation of metallic glasses. J Appl Phys 116(14):143503–143510

Chen K, Yu Y, Zhang Z, Shi SQ (2016) Shock-induced time-dependent strength behavior in amorphous alloys from a microscopic view. Scr Mater 120:62–66

Hao SG, Wang CZ, Kramer MJ, Ho KM (2010) Microscopic origin of slow dynamics at the good glass forming composition range in Zr1−x Cu x metallic liquids. J Appl Phys 107(5):053511–053516

Peng HL, Li MZ, Wang WH, Wang C, Ho KM (2010) Effect of local structures and atomic packing on glass forming ability in Cu x Zr100−x metallic glasses. Appl Phys Lett 96(21901):30–32

Sha ZD, Feng YP, Li Y (2010) Statistical composition-structure-property correlation and glass-forming ability based on the full icosahedra in Cu–Zr metallic glasses. Appl Phys Lett 96:61903–61905

Lee J-C, Park K-W, Kim K-H, Fleury E, Lee B-J, Wakeda M, Shibutani Y (2007) Origin of the plasticity in bulk amorphous alloys. J Mater Res 22:3087–3097

Park KW, Jang J, Wakeda M, Shibutani Y, Lee JC (2007) Atomic packing density and its influence on the properties of Cu–Zr amorphous alloys. Scr Mater 57(9):805–808

Cheng YQ, Sheng HW, Ma E (2008) Relationship between structure, dynamics, and mechanical properties in metallic glass-forming alloys. Phys Rev B Condens Matter Mater Phys 78(1):1–7

Mattern N, Schöps A, Kühn U, Acker J, Khvostikova O, Eckert J (2008) Structural behavior of Cu x Zr100−x metallic glass (x = 35 − 70). J. Non Cryst Solids 354(10–11):1054–1060

Cheng YQ, Cao AJ, Sheng HW, Ma E (2008) Local order influences initiation of plastic flow in metallic glass: effects of alloy composition and sample cooling history. Acta Mater 56(18):5263–5275

Mattern N, Jovari P, Kaban I, Gruner S, Elsner A, Kokotin V, Franz H, Beuneu B, Eckert J (2009) Short-range order of Cu–Zr metallic glasses. J Alloy Compd 485:163–169

Lagogianni AE, Almyras G, Lekka CE, Papageorgiou DG (2009) Structural characteristics of Cu x Zr100−x metallic glasses by molecular dynamics simulations. J Alloys Compd 483(1):658–661

Li M, Wang C, Hao S, Kramer M, Ho K (2009) Structural heterogeneity and medium-range order in Zr x Cu100−x metallic glasses. Phys Rev B 80(18):1–7

Cheng YQ, Ma E, Sheng HW (2009) Atomic level structure in multicomponent bulk metallic glass. Phys Rev Lett 102(24):245501–245504

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Mendelev MI, Sordelet DJ, Kramer MJ (2007) Using atomistic computer simulations to analyze x-ray diffraction data from metallic glasses. J Appl Phys 102(4):043501–043507

Davison L, Graham RA (1979) Shock compression of solids. Phys Rep 55(4):255–379

Davison L (2008) Fundamentals of shock wave propagation in solids. Springer, Berlin Heidelberg

Okamoto H (2008) Cu–Zr (Copper–Zirconium). J Phase Equilibria Diffus 29(2):204

Debenedetti PG, Stillinger FH (2001) Supercooled liquids and the glass transition. Nature 410(March):259–267

Holian BL (1998) Plasticity induced by shock waves in nonequilibrium molecular-dynamics simulations. Science 280(5372):2085–2088

Meyers MA, Jarmakani H, Bringa EM, Remington BA (2009) Dislocations in shock compression and release. Dislocations Solids 15:91–197

Chen K, Yu Y, Zhang Z, Shi S (2016) Shock-induced time-dependent strength behavior in amorphous alloys from amicroscopic view. Scr Mater 120(15):62–66

Davis LA, Kavesh S (1975) Deformation and fracture of an amorphous metallic alloy at high pressure. J Mater Sci 10(3):453–459. doi:10.1007/BF00543690

Donovan PE (1989) A yield criterion for Pd40Ni40P20 metallic glass. Acta Metall 37(2):445–456

Flores KM, Dauskardt RH (2001) Mean stress effects on flow localization and failure in a bulk metallic glass. Acta Mater 49(13):2527–2537

Lewandowski JJ, Lowhaphandu P (2002) Effects of hydrostatic pressure on the flow and fracture of a bulk amorphous metal. Philos Mag A 82(17–18):3427–3441

Lowhaphandu P, Montgomery SL, Lewandowski JJ (1999) Effects of superimposed hydrostatic pressure on flow and fracture of a Zr–Ti–Ni–Cu–Be bulk amorphous alloy. Scr Mater 41(1):19–24

Lu J, Ravichandran G (2003) Pressure-dependent flow behavior of Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass. J Mater Res 18(9):2039–2049

Vaidyanathan R, Dao M, Ravichandran G, Suresh S (2001) Study of mechanical deformation in bulk metallic glass through instrumented indentation. Acta Mater 49(18):3781–3789

Peker A, Johnson WL (1993) A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl Phys Lett 63(17):2342–2344

Acknowledgements

PW is supported by China Scholarship Council No. 201606840102. The authors acknowledge University of Florida Research Computing for providing computational resources and support that have contributed to the research results reported in this publication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, P., Demaske, B., Spearot, D.E. et al. Shock compression of Cu x Zr100−x metallic glasses from molecular dynamics simulations. J Mater Sci 53, 5719–5732 (2018). https://doi.org/10.1007/s10853-017-1666-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1666-5