Abstract

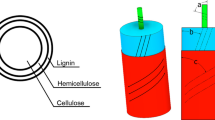

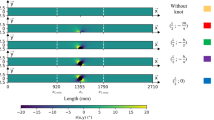

Experimental observations have shown that most of plant fibres are characterised by an intricate structure, morphology and organisation. This complex geometrical characteristics may affect the mechanical behaviour of this kind of natural fibres and contribute to the high variability of their mechanical properties. So, this study proposes a numerical investigation on the relationship between the cross-sectional shape of primary hemp bast fibres and their tensile behaviour. A 3D viscoelastic model based on finite element method is used for this study. Real and elliptical simplified cross-sectional shapes are considered. Results of the tensile test simulations clearly show the strong influence of the degree of ellipticity on the tensile response of the fibre, and more exactly on the shape of the nonlinearity of the response. Results also show that this morphologic effect is strongly related and coupled to structural parameters and physical mechanisms, such as the cellulose microfibrils angle and the viscoelastic behaviour of the material of the fibre wall. Geometric issues could then contribute to explain the different types of tensile behaviour experimentally observed and deserve to be taken into account in plant fibre models.

Similar content being viewed by others

References

Summerscales J, Dissanayake N, Virk A, Hall W (2010) A review of bast fibres and their composites. Part 2 composites. Compos Part A Appl Sci Manuf 41:1336–1344

Bledzki A (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24(2):221–274

Faruk O, Bledzki AK, Fink H-P, Sain M (2012) Biocomposites reinforced with natural fibers: 20002010. Prog Polym Sci 37(11):1552–1596

Shah DU, Schubel PJ, Clifford MJ, Licence P (2012) The tensile behavior of off-axis loaded plant fiber composites: an insight on the nonlinear stress-strain response. Polym Compos 33(9):1494–1504

Lebrun G, Couture A, Laperrière L (2013) Tensile and impregnation behavior of unidirectional hemp/paper/epoxy and flax/paper/epoxy composites. Compos Struct 103:151–160

Scida D, Assarar M, Poilâne C, Ayad R (2013) Influence of hygrothermal ageing on the damage mechanisms of flax-fibre reinforced epoxy composite. Compos Part B Eng 48:51–58

Poilâne C, Cherif ZE, Richard F, Vivet A, Ben Doudou B, Chen J (2014) Polymer reinforced by flax fibres as a viscoelastoplastic material. Compos Struct 112:100–112

Silva FdA, Chawla N, Filho R D d T (2008) Tensile behavior of high performance natural (sisal) fibers. Compos Sci Technol 68(15–16):3438–3443

Sedighi Gilani M (2006) A micromechanical approach to the behaviour of single wood fibers and wood fracture at cellular level. Ph.D. thesis

Duval A, Bourmaud A, Augier L, Baley C (2011) Influence of the sampling area of the stem on the mechanical properties of hemp fibers. Mater Lett 65(4):797–800

Placet V, Cisse O, Boubakar ML (2012) Influence of environmental relative humidity on the tensile and rotational behaviour of hemp fibres. J Mater Sci 47(7):3435–3446. doi:10.1007/s10853-011-6191-3

Nilsson T, Gustafsson PJ (2007) Influence of dislocations and plasticity on the tensile behaviour of flax and hemp fibres. Compos Part A Appl Sci Manuf 38(7):1722–1728

Placet V, Trivaudey F, Cisse O, Gucheret-Retel V, Boubakar ML (2012) Diameter dependence of the apparent tensile modulus of hemp fibres: a morphological, structural or ultrastructural effect? Compos Part A Appl Sci Manuf 43(2):275–287

Trivaudey F, Placet V, Guicheret-Retel V, Boubakar ML (2015) Nonlinear tensile behaviour of elementary hemp fibres. Part II: modelling using an anisotropic viscoelastic constitutive law in a material rotating frame. Compos Part A Appl Sci Manuf 68:346–355

Altaner CM, Jarvis MC (2008) Modelling polymer interactions of the molecular Velcro’ type in wood under mechanical stress. J Theor Biol 253(3):434–445

Keckes J, Burgert I, Frühmann K, Müller M, Kölln K, Hamilton M, Burghammer M, Roth SV, Stanzl-Tschegg S, Fratzl P (2003) Cell-wall recovery after irreversible deformation of wood. Nat Mater 2(12):810–813

Mostefai N, Hamzaoui R, Guessasma S, Aw A, Nouri H (2015) Microstructure and mechanical performance of modified hemp fibre and shiv mortars: discovering the optimal formulation. Mater Des 84:359–371

Marklund E, Varna J (2009) Modeling the effect of helical fiber structure on wood fiber composite elastic properties. Appl Compos Mater 16(4):245–262

Astley RJ, Stol KA, Harrington JJ (1998) Modelling the elastic properties of softwood: Part II: the cellular microstructure. Holz als Roh und Werkst 56(1):43–50

Harrington JJ, Astley RJ, Booker R (1998) Modelling the elastic properties of softwood: Part I: the cell-wall lamellae. Holz als Roh und Werkst 56(1):37–41

Burgert I, Frühmann K, Keckes J, Fratzl P, Stanzl-Tschegg S (2005) Properties of chemically and mechanically isolated fibres of spruce (Picea abies [L.] Karst.). Part 2: twisting phenomena. Holzforschung 59(2):247–251

Bourmaud A, Morvan C, Bouali A, Placet V, Perré P, Baley C (2013) Relationships between micro-fibrillar angle, mechanical properties and biochemical composition of flax fibers. Ind Crops Prod 44:343–351

Page DH, El-Hosseiny F, Winkler K (1971) Behaviour of single wood fibres under axial tensile strain. Nature 229(5282):252–253

Placet V, Cisse O, Lamine Boubakar M (2014) Nonlinear tensile behaviour of elementary hemp fibres. Part I: investigation of the possible origins using repeated progressive loading with in situ microscopic observations. Compos Part A Appl Sci Manuf 56:319–327

Thomason JL, Carruthers J, Kelly J, Johnson G (2011) Fibre cross-section determination and variability in sisal and flax and its effects on fibre performance characterisation. Compos Sci Technol 71(7):1008–1015

Charlet K, Jernot J-P, Breard J, Gomina M (2010) Scattering of morphological and mechanical properties of flax fibres. Ind Crops Prod 32(3):220–224

Blake AW, Marcus SE, Copeland JE, Blackburn RS, Knox JP (2008) In situ analysis of cell wall polymers associated with phloem fibre cells in stems of hemp, Cannabis sativa L. Planta 228(1):1–13

Placet V, Méteau J, Froehly L, Salut R, Boubakar ML (2014) Investigation of the internal structure of hemp fibres using optical coherence tomography and Focused Ion Beam transverse cutting. J Mater Sci 49(24):8317–8327. doi:10.1007/s10853-014-8540-5

Mattrand C, Béakou A, Charlet K (2014) Numerical modeling of the flax fiber morphology variability. Compos Part A Appl Sci Manuf 63:10–20

Schäfer T, Honermeier B (2006) Effect of sowing date and plant density on the cell morphology of hemp (Cannabis sativa L.). Ind Crops Prod 23(1):88–98

Crônier D, Monties B, Chabbert B (2005) Structure and chemical composition of bast fibers isolated from developing hemp stem. J Agric Food Chem 53(21):8279–8289

Sankari HS (2000) Comparison of bast fibre yield and mechanical fibre properties of hemp (Cannabis sativa L.) cultivars. Ind Crops Prod 11(1):73–84

Zafeiropoulos NE, Baillie CA (2007) A study of the effect of surface treatments on the tensile strength of flax fibres: Part II. Application of Weibull statistics. Compos Part A Appl Sci Manuf 38(2):629–638

Baley C (2002) Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos Part A Appl Sci Manuf 33(7):939–948

Bodros E, Baley C (2008) Study of the tensile properties of stinging nettle fibres (Urtica dioica). Mater Lett 62(14):2147–2149

Virk AS, Hall W, Summerscales J (2012) Modulus and strength prediction for natural fibre composites. Mater Sci Technol 28(7):864–871

Joffre T, Miettinen A, Berthold F, Gamstedt EK (2014) X-ray micro-computed tomography investigation of fibre length degradation during the processing steps of short-fibre composites. Compos Sci Technol 105:127–133

Ntenga R, Beakou A (2011) Structure, morphology and mechanical properties of Rhectophyllum camerunense (RC) plant-fiber. Part I: statistical description and image-based reconstruction of the cross-section. Comput Mater Sci 50(4):1442–1449

Gassan J, Chate A, Bledzki AK (2001) Calculation of elastic properties of natural fibers. J Mater Sci 36(15):3715–3720. doi:10.1023/A:1017969615925

Boubakar ML, Vang L, Trivaudey F, Perreux D (2003) A mesomacro finite element modelling of laminate structures. Compos Struct 60(3):275–305

Guicheret-Retel V, Cisse O, Placet V, Beaugrand J, Pernes M, Boubakar ML (2015) Creep behaviour of single hemp fibres. Part II: influence of loading level, moisture content and moisture variation. J Mater Sci 50(5):2061–2072. doi:10.1007/s10853-014-8768-0

Cisse O, Placet V, Guicheret-Retel V, Trivaudey F, Boubakar ML (2015) Creep behaviour of single hemp fibres. Part I: viscoelastic properties and their scattering under constant climate. J Mater Sci 50(4):1996–2006. doi:10.1007/s10853-014-8767-1

Keller A (2003) Compounding and mechanical properties of biodegradable hemp fibre composites. Compos Sci Technol 63(9):1307–1316

Cisse O (2014) Caractérisation du comportement hygro-mécanique des fibres liberiennes élémentaires issues du chanvre. Ph.D. Thesis

Charlet, K (2008) Contribution à l’ ’etude de composites unidirectionnels renforcés par des fibres de lin : relation entre la microstructure de la fibre et ses propriés m écaniques. Ph.D. Thesis

Osborne GG (1935) Micro-analysis of textile fibres: Part IV. Observations on the structure of flax, manila and jute. Text Res J 5(10):431–459

Weaver PM (2003) The effect of extension/twist anisotropy on compression buckling in cylindrical shells. Compos Part B Eng 34(3):251–260

Pagano NJ, Halpin JC, Whitney JM (1994) Tension buckling of anisotropic cylinders. In: Gladwell GML, Reddy JN (eds) Mechanical composite materials, vol 34. Springer, Dordrecht, pp 17–30

Page DH, El-Hosseiny F (1983) The mechanical properties of single pulp fibres. Part VI. Fibril angle and the shape of stress-strain curve. J Pulp Pap Sci 84:TR99–TR100

Acknowledgements

The authors would like to acknowledge Camille François, Ph.D. student at the Department of Applied Mechanics of the FEMTO-ST Institute for preparing the hemp samples and providing the images used for the microscopic observations.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Del Masto, A., Trivaudey, F., Guicheret-Retel, V. et al. Nonlinear tensile behaviour of elementary hemp fibres: a numerical investigation of the relationships between 3D geometry and tensile behaviour. J Mater Sci 52, 6591–6610 (2017). https://doi.org/10.1007/s10853-017-0896-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0896-x