Abstract

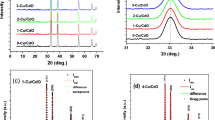

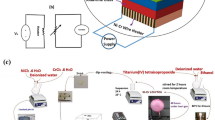

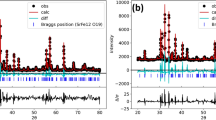

Two series of Fe thin films have been electrodeposited onto polycrystalline porous Al substrates using two baths: iron chloride (FeCl2) and iron sulfate (FeSO4). The texture, strain, and grain size values have been derived from X-ray diffraction experiments. Scanning electron microscopy has been employed for surface morphology. The magnetic properties were inferred from hysteresis curves that were obtained from a vibrating sample magnetometer; the external magnetic field was applied in different directions of the film plane and also perpendicular to the film. Hysteresis curves have been obtained at low temperatures (120 K (−153 °C) to room temperature). We investigate the effects of Al porosity, bath type, and deposition rate on physical properties of these Fe films. A correlation between the structural and magnetic properties is made. Different mechanisms responsible for the coercive field (H C) behavior have also been investigated.

Similar content being viewed by others

References

Díaz SL, Calderón JA, Barcia OE, Mattos OR (2008) Electrodeposition of iron in sulphate solutions. Electrochim Acta 53:7426–7435

Su C, He F, Ju H, Zhang Y, Wang E (2009) Electrodeposition of Ni, Fe and Ni–Fe alloys on a 316 stainless steel surface in a fluorborate bath. Electrochim Acta 54:6257–6263

Allongue P, Maroun F (2010) Electrodeposited magnetic layers in the ultrathin limit. MRS Bull 35:761

Izaki M (2010) Electrodeposition of iron and iron alloys. In: Schlesinger M, Paunovic M (eds) Modern electroplating, 5th edn. Wiley, Hoboken, pp 309–326

Park D-Y, Yoo BY, Kelcher S, Myung NV (2006) Electrodeposition of low-stress high magnetic moment Fe-rich FeCoNi thin films. Electrochim Acta 51:2523–2530

Heinrich B, Purcell ST, Dutcher JR, Urquhart KB, Cochran JF, Arrott AS (1988) Structural and magnetic properties of ultrathin Ni/Fe bilayers grown epitaxiaiiy on Ag(001). Phys Rev 38:12879

Layadi A, Artman JO, Hall BO, Hoffman RA, Jensen CL, Chakrabarti DJ, Saunders DA (1988) FMR in evaporated single and multilayer thin Fe films. J Appl Phys 64(10):5760–5762

Celinski Z, Uquhart KB, Heinrich B (1997) Using ferromagnetic resonance to measure the magnetic moments of ultrathin films. J Magn Magn Mater 166:6–26

Rezende SM, Chesman C, Lucena MA, de Moura MC, Azevedo A, de Aguir FM (1999) Biquadratic coupling in sputtered Fe/Cr/Fe still in need of a new mechanism. J Appl Phys 85:5892–5894

Sadashivaiah PJ, Sankarappa T, Sujatha T, Santoshkumar R, Rawat P Sarvanan, Bhatnagar AK (2010) Structural, magnetic and electrical properties of Fe/Cu/Fe films. Vacuum 85(3):466–473

D’Orazio F, Gubbiotti G, Lucari F, Tassoni E (2002) Magnetic and structural properties of Fe/Al multilayers. J Magn Magn Mater 242–245:535–537

Ghebouli B, Chérif S-M, Layadi A, Helifa B, Boudissa M (2007) Structural and magnetic properties of evaporated Fe thin films on Si(111), Si(100) and glass substrates. J Magn Magn Mater 312:194–199

Mebarki M, Layadi A, Guittoum A, Benabbas A, Ghebouli B, Saad M, Menni N (2011) Structural and electrical properties of evaporated Fe thin films. Appl Surf Sci 257:7025–7029

Mebarki M, Layadi A, Kerkache L, Benabbas A, Tiercelin N, Preobrazhensky V, Pernod P (2014) Effect of thickness and deposition rate on the structural and magnetic properties of evaporated Fe/Al thin films. J Supercond Nov Magn 27(8):1951–1957

Mebarki M, Layadi A, Kerkache L, Tiercelin N, Preobrazhensky V, Pernod P (2015) Surface morphology and magnetic properties of evaporated Fe/Si and Fe/glass thin films. Appl Phys A 120(1):97–104

Chen Gang, Cao Peng, He Yuehui, Shen Peizhi, Gao Haiyan (2012) Effect of aluminium evaporation loss on pore characteristics of porous FeAl alloys produced by vacuum sintering. J Mater Sci 47:1244–1250. doi:10.1007/s10853-011-5771-6

Osaka T (1999) Recent development of magnetic recording head core materials by plating method. Electrochim Acta 44(21):3885–3890

Park D-Y, Myung NV, Schwartz M, Nobe K (2002) Nanostructured magnetic CoNiP electrodeposits: structure-property relationships. Electrochim Acta 47:2893–2900

Chiu A, Croll I, Heim DE, Jones RE Jr, Kasiraj P, Klassen KB, Simmons CDRG (1996) Thin-film inductive heads. IBM J Res Dev 40(3):283–300

Andricacos PC, Robertson N (1998) Future directions in electroplated materials for thin-film recording heads. IBM J Res Dev 42(5):671–680

Protsenko VS, Vasil’eva EA, Smenova IV, Baskevich AS, Danilenko IA, Konstantinova TE, Danilov FI (2015) Electrodeposition of Fe and composite Fe/ZrO2 coatings from a methanesulfonate electrolyte. Surf Eng Appl Electrochem 51:65–75

Abd El Meguid EA, Abd El Rehim SS, Moustafa EM (2003) Electroplating of iron from alkaline gluconate baths. Thin Solid Films 443(1–2):53–59

Hou XW, Liu SB, Yang SL, Li JP, Guo B (2013) Electrical and magnetic properties of electrodeposited Fe-based alloys used for thin film transformer. Sci China Technol Sci 56(1):84–88

Svedberg EB, Mallett JJ, Bendersky LA, Roy AG, Egelhoff WF Jr, Moffat TP (2006) A structural study of electrodeposited Fe on n-GaAs (001). J Electrochem Soc 153(12):C807–C813

Motoyama M, Fukunaka Y, Sakka T, Ogatab YH (2006) Effect of surface pH on electrodeposited Ni films. J Electrochem Soc 153:C502–C508

Lallemand F, Ricq L, Wery M, Berc¸ot P, Pagetti J (2004) The influence of organic additives on the electrodeposition of iron-group metals and binary alloy from sulfate electrolyte. Appl Surf Sci 228:326–333

Bhuiyan MS, Taylor BJ, Paranthaman M, Thompson JR, Sinclair JW (2008) Microstructure and magnetic properties of electrodeposited cobalt films. J Mater Sci 43:1644–1649. doi:10.1007/s10853-007-2383-2

Sueyoshi T (1987) Morphology and porous texture of iron fine particles with relation to their magnetic properties. J Mater Sci 22:860–866. doi:10.1007/BF01103521

Kim D, Park D-Y, Yoo BY, Sumodjo PTA, Myung NV (2003) Magnetic properties of nanocrystalline iron group thin film alloys electrodeposited from sulfate and chloride baths. Electrochim Acta 48(7):819–830

Gundel A, Devolder T, Chappert C, Schmidt JE, Cortes R, Allongue P (2004) Electrodeposition of Fe/Au(1 1 1) ultrathin layers with perpendicular magnetic anisotropy. Phys B 354(1–4):282–285

Zarpellon J, Jurca HF, Klein JJ, Schreiner WH, Mattoso N, Mosca DH (2007) Electrodeposition of Fe thin films on Si(1 1 1) surfaces in the presence of sodium saccharin. Electrochim Acta 53:2002–2008

Jartych E, Zurawicz JK, Maczka E, Borc J (2001) Preparation of thin iron films by electrodeposition and characterization of their local magnetic properties. Mater Chem Phys 72(3):356–359

Jartych E, Chocyk D, Budzynski M, Jalochoski M (2001) Surface morphology and local magnetic properties of electrodeposited thin iron layers. Appl Surf Sci 180(3):246–254

Mebarki M, Layadi A, Khelladi MR, Azizi A, Tiercelin N, Preobrazhensky V, Pernod P (2016) Structural and magnetic properties of Fe films electrodeposited on Al substrates. Metall Mater Trans A 47:3677–3683

Qin Xu, Yang Yuhua, Jianjun Gu, Li Ziyue, Sun Huiyuan (2012) Influence of Al substrate on the optical properties of porous anodic alumina films. Mater Lett 74:137–139

Koji H, Furuta H, Sekiya K, Nitta N, Harigai T, Hatta A (2013) Increased CNT growth density with an additional thin Ni layer on the Fe/Al catalyst film. Diam Relat Mater 36:1–7

Brajpuriya R (2010) Low temperature noncollinear behavior in ultrathin Fe/Al multilayer structures. J Appl Phys 107:083914

Budevski E, Staikow G, Lorenz WJ (2000) Electrocrystallization: Nucleation and growth phenomena. Electrochim Acta 45(15–16):2559–2574

Brice JC, Cundall JA, King AP (1966) Easy direction coercive force associated with domain wall motion in nickel-lron films. J Mater Sci 1:170–185. doi:10.1007/BF00550105

Herzer Giselher (2005) Anisotropies in soft magnetic nanocrystalline alloys. J Magn Magn Mater 294(2):99–106

Min H-G, Kim S-H, Li M, Wedding JB, Wang GC (1998) Thickness dependent coercivity of ultrathin co films on rough substrates: Cu buffered Si(111). Surf Sci 400:19–28

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Mebarki, M., Layadi, A., Khelladi, M.R. et al. Physical properties of Fe films electrodeposited on porous Al substrates. J Mater Sci 52, 4472–4482 (2017). https://doi.org/10.1007/s10853-016-0693-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0693-y