Abstract

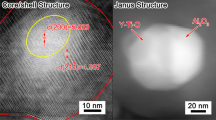

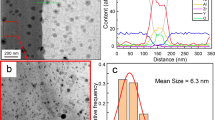

The oxide nanoparticles present in three oxide-dispersion-strengthened (ODS) Fe–12Cr–5Al alloys containing additions of (1) Y2O3 (125Y), (2) Y2O3 + ZrO2 (125YZ), and (3) Y2O3 + HfO2 (125YH), were investigated using transmission and scanning transmission electron microscopy. In all three alloys nano-sized (<3.5 nm) oxide particles distributed uniformly throughout the microstructure were characterized using advanced electron microscopy techniques. In the 125Y alloy, mainly Al2O3 and yttrium–aluminum garnet (YAG) phases (Y3Al5O12) were present, while in the 125YZ alloy, additional Zr(C,N) precipitates were identified. The 125YH alloy had the most complex precipitation sequence whereby in addition to the YAG and Al2O3 phases, Hf(C,N), Y2Hf2O7, and HfO2 precipitates were also found. The presence of HfO2 was mainly due to the incomplete incorporation of HfO2 powder during mechanical alloying of the 125YH alloy. The alloy having the highest total number density of the oxides, the smallest grain size, and the highest Vickers hardness was the 125YZ alloy indicating, that Y2O3 + ZrO2 additions had the strongest effect on grain size and tensile properties. High-temperature mechanical testing will be addressed in the near future, while irradiation studies are underway to investigate the irradiation resistance of these new ODS FeCrAl alloys.

Similar content being viewed by others

References

Zinkle SJ, Snead LL (2014) Designing radiation resistance in materials for fusion energy. Annu Rev Mater Res 44:241–267

Certain A, Kuchibhatla S, Shutthanandan V, Hoelzer DT, Allen TR (2013) Radiation stability of nanoclusters in nano-structured oxide dispersion strengthened (ODS) steels. J Nucl Mater 434:311–321

Yamamoto T, Odette GR, Miao P, Hoelzer DT, Bentley J, Hashimoto N, Tanigawa H, Kurtz RJ (2007) The transport and fate of helium in nanostructured ferritic alloys at fusion relevant He/dpa ratios and dpa rates. J Nucl Mater 367–370:399–410

Field KG, Hu X, Littrell KC, Yamamoto Y, Snead LL (2015) Radiation tolerance of neutron-irradiated model FeCrAl alloys. J Nucl Mater 465:746–755

Kimura A, Kasada R, Iwata N, Kishimoto H, Zhang CH, Isselin J, Dou P, Lee JH, Muthukumar N, Okuda T, Inoue M, Ukai S, Ohnuki S, Fujisawa T, Abe TF (2011) Development of Al added high-Cr ODS steels for fuel cladding of next generation nuclear systems. J Nucl Mater 417:176–179

Unocic KA, Pint BA (2014) Alloying and coating strategies for improved Pb–Li compatibility in DEMO-type fusion reactors. J Nucl Mater 455:330–334

Takaya S, Furukawa T, Aoto K, Müller G, Weisenburger A, Heinzel A, Inoue M, Okuda T, Abe F, Ohnuki S, Fujisawa T, Kimura A (2009) Corrosion behavior of Al-alloying high Cr-ODS steels in lead–bismuth eutectic. JNM 386–388:507–510

Stoloff NS (1966) In: Fracture: proceedings of conference on the physical basis of yield and fracture. Physical Society, London, p 68–76

Furukawa T, Ohtsuka S, Inoue M, Okuda T, Abe F, Ohnuki S, Fujisawa T, Kimura A (2009) Super ODS steels R&D for fuel cladding of next generation nuclear systems 4) mechanical properties at elevated temperatures. Proc ICAPP 2009:2204–2210

Dou P, Kimura A, Kasada R, Okuda T, Inoue M, Ukai S, Ohnuki S, Fujisawa T, Abe F (2014) TEM and HRTEM study of oxide particles in an Al-alloyed high-Cr oxide dispersion strengthened steel with Zr addition. JNM 444:441–453

Yu CZ, Oka H, Hashimoto N, Ohnuki S (2011) Development of damage structure in 16Cr–4Al ODS steels during electron-irradiation. J Nucl Mater 417:286–288

Zhang CH, Kimura A, Kasada R, Jang J, Kishimoto H, Yang YT (2011) Characterization of the oxide particles in Al-added high-Cr ODS ferritic steels. J Nucl Mater 417:221–224

Alinger MJ, Odette GR, Hoelzer DT (2009) On the role of alloy composition and processing parameters in nanocluster formation and dispersion strengthening in nanostuctured ferritic alloys. Acta Mater 57:392–406

Kasada R, Toda N, Yutani K, Cho HS, Kishimoto H, Kimura A (2007) Pre- and post-deformation microstructures of oxide dispersion strengthened ferritic steels. J Nucl Mater 367:222–228

Unocic KA, Hoelzer DT, Pint BA (2015) Microstructure and environmental resistance of low Cr ODS FeCrAl. Mater High Temp 32:123–132

Pint BA, Dryepondt S, Unocic KA, Hoelzer DT (2014) Development of ODS FeCrAl for compatibility in fusion and fission energy applications. JOM Mag 66:2458–2466

Takaya S, Furukawa T, Müller G, Heinzel A, Jianu A, Weisenburger A, Aoto K, Inoue M, Okuda T, Abe F, Ohnuki S, Fujisawa T, Kimura A (2012) Al-containing ODS steels with improved corrosion resistance to liquid lead–bismuth. J Nucl Mater 428:125–130

Ohnuki S, Hashimoto N, Ukai S, Kimura A, Inoue M, Kaito T, Fujisawa T, Okuda T, Abe F (2009) Super ODS steels R&D for fuel cladding of next generation nuclear systems 2) effect of minor alloying elements. In: Proceedings of the ICAPP 2009

Mazzoni AD, Conconi MS (2002) Synthesis of group IVB metals oxicarbides by carboreduction reactions. Mater Res 5:459–466

Arias D, Abriata JP (1988) The Fe–Zr (iron–zirconium) system. Bull Alloy Phase Diagr 9:597–604

Dawson K, Tatlock GJ (2014) Characterisation of nanosized oxides in ODM401 oxide dispersion strengthened steel. J Nucl Mater 444:252–260

Wasilkowska A, Bartsch M, Messerschmidt U, Herzog R, Czyrska-Filemonowicz A (2003) Creep mechanisms of ferritic oxide dispersion strengthened alloys. J Mater Process Technol 133:218–224

Schneibel JH, Heilmaier M, Blum W, Hasemann G, Shanmugasundaram T (2011) Temperature dependence of the strength of fine- and ultrafine-grained materials. Acta Mater 59:1300–1308

Dubiel B, Wróbel M, Ennis PJ, Czyrska-Filemonowicz A (1997) Microstructure of INCOLOY MA956 after low and high temperature deformation. Scr Mater 37:1215–1220

Czyrska-Filemonowicz A, Clemens D, Quadakkers WJ (1995) The effect of high temperature exposure on the structure and oxidation behaviour of mechanically alloyed ferritic ODS alloys. J Mater Process Technol 53:93–100

Czyrska-Filemonowicz A, Dubiel B (1997) Mechanically alloyed, ferritic oxide dispersion strengthened alloys: structure and properties. J Mater Process Technol 64:53–64

Krautwasser P, Czyrska-Filemonowicz A, Widera M, Carsughi F (1994) Thermal stability of dispersoids in ferritic oxide-dispersion-strengthened alloys. Mater Sci Eng A 177:199–208

Konys J, Krauss W, Voss Z, Wedemeyer O (2007) Comparison of corrosion behavior of bare and hot-dip coated EUROFER steel in flowing Pb–17Li. J Nucl Mater 367–370:1144–1149

Klimenkov M, Moslang A, Lindau R (2008) EELS analysis of complex precipitates in PM 2000 steel. Eur Phys J Appl Phys 42:293–303

Klimiankou M, Lindau R, Moslang A, Schroder J (2005) TEM study of PM 2000 steel. Powder Metall 48:277–287

Dubiel B, Osuch W, Wróbel M, Ennis PJ, Czyrska-Filemonowicz A (1995) Correlation of the microstructure and the tensile deformation of INCOLOY MA956. J Mater Process Technol 53:121–130

Ukai S, Nishida T, Okada H, Okuda T, Fujiwara M, Asabe K (1997) Development of oxide dispersion strengthened ferritic steels for FBR core application (I). J Nucl Sci Technol 34:256–263

Hald J, Korcakova L (2003) Precipitate stability in creep resistant ferritic steels—experimental investigations and modelling. ISIJ Int 43:420–427

Kasada R, Toda N, Cho HS, Kimura A (2005) In: Proceedings of the 2005 international congress on advances in nuclear power plants (ICAPP’05), pp 1703–1711

Pint BA, Hoelzer DT, Shin D, Unocic KA (2012) Development of ODS FeCrAl for fusion reactor applications. Fusion React Mater Program 53:10–14

Acknowledgements

Research sponsored by the US Department of Energy (DOE), Office of Fusion Energy Sciences, Fusion Energy Materials Program. A portion of the microscopy was performed as part of a user proposal at ORNL’s Center for Nanophase Materials Sciences (CNMS), which is a US Department of Energy, Office of Science User Facility, and also some of the microscopy research was performed, in part, using instrumentation (FEI Talos F200X S/TEM) provided by the Department of Energy, Office of Nuclear Energy, Fuel Cycle R&D Program and the Nuclear Science User Facilities. D. W. Coffey, T. M. Lowe, M. S. Stephens, and T. S. Geer assisted with the experimental work. D. Cullen and K. G. Field provided comments on the results and manuscript and S. Dryepondt provided PM2000.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Unocic, K.A., Pint, B.A. & Hoelzer, D.T. Advanced TEM characterization of oxide nanoparticles in ODS Fe–12Cr–5Al alloys. J Mater Sci 51, 9190–9206 (2016). https://doi.org/10.1007/s10853-016-0111-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0111-5