Abstract

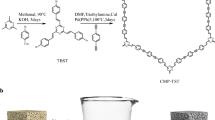

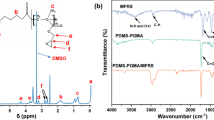

To fabricate superhydrophobic membranes for oil/water separation, a mesh serving as a support is usually required for improving mechanical properties and rendering a micro-scale porous structure. Herein, we develop a simple spraying-coating process for producing superhydrophobic and superoleophilic porous polymer membranes without meshes as supports from a fluorinated polyarylester polydimethylsiloxane block copolymer (PAR-b-PDMS). It is exciting that the surface morphology of the PAR-b-PDMS membranes can be controlled by the copolymer solution concentration. The PAR-b-PDMS membranes are endowed with promising superhydrophobicity and superoleophilicity, displaying excellent oil affinity and low water adhesion behaviors. Significantly, the PAR-b-PDMS membranes exhibit fast and efficient separation for oil/water mixtures with separation efficiency as high as 99 %. And after 50 cycles of oil/water separation, the as-prepared membranes can still maintain stable superhydrophobicity and high separation efficiency, indicating good recyclability and durability. Moreover, the fabrication approach presented here can be easily scaled up for producing polymer membranes on a large scale, which makes it very promising for practical oil/water separation.

Similar content being viewed by others

References

Kota AK, Kwon G, Choi W, Mabry JM, Tuteja A (2012) Hygro-responsive membranes for effective oil–water separation. Nat Commun 3:1025–1032

Tao M, Xue L, Liu F, Jiang L (2014) An intelligent superwetting PVDF membrane showing switchable transport performance for oil/water separation. Adv Mater 26:2943–2948

Gondal MA, Sadullah MS, Dastageer MA, McKinley GH, Panchanathan D, Varanasi KK (2014) Study of factors governing oil–water separation process using TiO2 films prepared by spray deposition of nanoparticle dispersions. ACS Appl Mater Interfaces 6:13422–13429

Xue Z, Cao Y, Liu N, Feng L, Jiang L (2014) Special wettable materials for oil/water separation. J Mater Chem A 2:2445–2460

Ge B, Men X, Zhu X, Zhang Z (2015) A superhydrophobic monolithic material with tunable wettability for oil and water separation. J Mater Sci 50:2365–2369. doi:10.1007/s10853-014-8756-4

Shang Y, Si Y, Raza A, Yang L, Mao X, Ding B, Yu J (2012) An in situ polymerization approach for the synthesis of superhydrophobic and superoleophilic nanofibrous membranes for oil–water separation. Nanoscale 4:7847–7854

Feng L, Zhang Z, Mai Z, Ma Y, Liu B, Jiang L, Zhu D (2004) A superhydrophobic and superoleophilic coating mesh film for the separation of oil and water. Angew Chem Int Ed 43:2012–2014

Zhang JP, Seeger S (2011) Polyester materials with superwetting silicone nanofilaments for oil/water separation and selective oil absorption. Adv Funct Mater 21:4699–4704

Lee C, Baik S (2010) Vertically-aligned carbon nanotube membrane filters with superhydrop- hobicity and superoleophilicity. Carbon 48:2192–2197

Wang C, Yao T, Wu J, Ma C, Fan Z, Wang Z, Cheng Y, Lin Q, Yang B (2009) Facile approach in fabricating superhydrophobic and superoleophilic surface for water and oil Mixture separation. ACS Appl Mater Interfaces 1:2613–2617

Wang CF, Tzeng FS, Chen HG, Chang CJ (2012) Ultraviolet-durable superhydrophobic zinc oxide-coated mesh films for surface and under water–oil capture and transportation. Langmuir 28:10015–10019

Li BY, Jiang BB, Fauth DJ, Gray ML, Pennline HW, Richards GA (2011) Innovative nano-layered solid sorbents for CO2 capture. Chem Commun 47:1719–1721

Li Y, Xiao W, Xiao K, Berti L, Luo J, Tseng HP, Fung G, Lam KS (2012) Well-defined, reversible boronate crosslinked nanocarriers for targeted drug delivery in response to acidic pH values and cis-diols. Angew Chem Int Ed 51:2864–2869

Wang X, Ding B, Yu J, Wang M (2011) Engineering biomimetic superhydrophobic surfaces of electrospun nanomateriales. Nano Today 6:510–530

Ganesh VA, Raut HK, Nair AS, Ramakrishna S (2011) A review on self-cleaning coatings. J Mater Chem 21:16304–16322

Levkin PA, Svec F, Fréchet JM (2009) Porous polymer coatings: a versatile approach to superhydrophobic surfaces. Adv Funct Mater 19:1993–1998

Shirtcliffe NJ, McHale G, Newton MI (2011) The superhydrophobicity of polymer surfaces: recent developments. J Polym Sci Part B 49:1203–1217

Hwang HS, Kim NH, Lee SG, Lee DY, Cho K, Park I (2011) Facile fabrication of transparent superhydrophobic surfaces by spray deposition. ACS Appl Mater Interfaces 3:2179–2183

Li H, Zhao Y, Yuan X (2013) Facile preparation of superhydrophobic coating by spraying a fluorinated acrylic random copolymer micelle solution. Soft Matter 9:1005–1009

Li H, Zhao X, Chu G, Zhang S, Yuan X (2014) One-step fabrication of a superhydrophobic polymer surface from an acrylic copolymer containing POSS by spraying. RSC Adv 4:62694–62697

Tu CW, Tsai CH, Wang CF, Kuo SW, Chang FC (2007) Fabrication of superhydrophobic and superoleophilic polystyrene surfaces by a facile one-step method. Macromol Rapid Commun 28:2262–2266

Rohrbach K, Li Y, Zhu H, Liu Z, Dai J, Andreasen J, Hu L (2014) A cellulose based hydrophilic, oleophobic hydrated filter for water/oil separation. Chem Commun 50:13296–13299

Rached R, Hoppe S, Jonquieres A, Lochon P, Pla F (2006) A new macroinitiator for the synthesis of triblock copolymers PA12-b-PDMS-b-PA12. J Appl Polym Sci 102:2818–2831

Lin J, Ding B, Yu J, Hsieh Y (2010) Direct fabrication of highly nanoporous polystyrene fibers via electrospinning. ACS Appl Mater Interfaces 2:521–528

McCann JT, Marquez M, Xia Y (2006) Highly porous fibers by electrospinning into a cryogenic liquid. J Am Chem Soc 128:1436–1437

Jiang L, Zhao Y, Zhai J (2004) A lotus-leaf-like superhydrophobic surface: a porous microsphere/nanofiber composite film preppared by electrohydrodynamics. Angew Chem Int Ed 43:4338–4341

Ma M, Mao Y, Gupta M, Gleason KK, Rutledge GC (2005) Superhydrophobic fabrics produced by electrospinning and chemical vapor deposition. Macromolecules 38:9742–9748

Acknowledgments

The authors thank the National Natural Science Foundation of China (51103061), and Research Fund for the Doctoral Program of University of Jinan.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (AVI 3095 kb)

Rights and permissions

About this article

Cite this article

Li, H., Zhao, X., Wu, P. et al. Facile preparation of superhydrophobic and superoleophilic porous polymer membranes for oil/water separation from a polyarylester polydimethylsiloxane block copolymer. J Mater Sci 51, 3211–3218 (2016). https://doi.org/10.1007/s10853-015-9632-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9632-6