Abstract

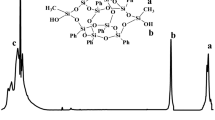

A series of environmentally friendly and sustainable polyurethanes using epoxy soybean oil as feedstock were synthesized with the introduction of double-decker silsesquioxane. Feature is that through the two-step polymerization, double-decker octaphenylsilsesquioxanetetraol was added to partially replace 1,4-butanediol acting as chain extender, and petroleum-based polyol was effectively replaced for polyurethane synthesis. On top of that, POSS tetraol was prepared and characterized by 1H NMR and MALDI-TOF MS. As for the organic–inorganic hybrid nanocomposites, their structures and properties were investigated by FTIR, DSC, TGA, SEM, tensile test techniques, and static contact angle. DSC analysis showed that covalent incorporation of POSS into the PU network would increase the glass transition temperature (T g) of the systems. TG analysis demonstrated that the hybrid nanocomposites were indeed more oxidative thermal stable, compared to virgin polyurethane especially at high temperature. SEM revealed that both nano- and micro-sized POSS aggregates were shown to be dispersed heterogeneously in the polyurethane matrix, despite the expectation to be dispersed or corporate into molecular chains by chemical bonding between OH and NCO. According to the tensile test results, POSS-containing nanocomposites exhibited an increased modulus with an increasing POSS concentration at low POSS content, and with high loading, these values would decline. The results of the static contact angles revealed that the hydrophobicity of the hybrid material was significantly improved with the inclusion of POSS.

Similar content being viewed by others

References

Shouming W, Hayakawa T, Kakimoto M-a, Oikawa H (2008) Synthesis and characterization of organosoluble aromatic polyimides containing POSS in main chain derived from double-decker-shaped silsesquioxane. Macromolecules 41:3481–3487

Kuoa SW, Changb FC (2011) POSS related polymer nanocomposites. Prog Polym Sci 36:1649–1696

Tamaki R, Tanaka Y, Asuncion MZ, Choi J, Laine RM (2001) Octa(aminophenyl)silsesquioxane as a nanoconstruction Site. J Am Chem Soc 123:12416–12417

Ak M, Gacal B, Kiskan B, Yagci Y, Toppare L (2008) Enhancing electrochromic properties of polypyrrole by silsesquioxane nanocages. Polymer 49:2202–2210

Neumann D, Fisher M, Tran L, Matisons JG (2002) Synthesis and characterization of an isocyanate functionalized polyhedra oligosilsesquioxane and the subsequent formation of an organic-inorganic hybrid polyurethane. J Am Chem Soc 124:13998–13999

Laine RM, Roll MF (2011) Polyhedral phenylsilsesquioxanes. Macromolecules 44:1073–1109

Cai H, Kai X, Liu X, Fua Z, Chen M (2012) A facile synthesis of octa(carboxyphenyl)silsesquioxane. Dalton Trans 41:6919–6921

Hongyao X, Yang B, Wang J, Guang S, Li C (2007) Preparation, Tg improvement, and thermal stability enhancement mechanism of soluble poly(methyl methacrylate) nanocomposites by incorporating octavinyl polyhedral oligomeric silsesquioxanes. J Polym Sci Pol Chem 45:5308–5317

Gnanasekaran D, Ajit Walter P, Reddy BSR (2013) Influence of moieties on morphology, thermal, and dielectric properties in polyamide-polyhedral oligomeric silsequioxanes nanocomposites. Polym Eng Sci 53:1637–1644

Kun W, Kandola BK, Kandare E, Yuan H (2011) Flame retardant effect of polyhedral oligomeric silsesquioxane and triglycidyl isocyanurate on glass fibre-reinforced epoxy composites. Polym Compos 32:378–389

Wei K, Wang L, Zheng S (2013) Organic–inorganic polyurethanes with 3, 13-dihydroxypropyloctaphenyl double-decker silsesquioxane chain extender. Polym Chem 4:1491–1501

Bourbigot S, Turf T, Bellayer S, Duquesne S (2009) Polyhedral oligomeric silsesquioxane as flame retardant for thermoplastic polyurethane. Polym Degrad Stab 94:1230–1237

Musto P, Abbate M, Pannico M, Scarinzi G, Ragosta G (2012) Improving the photo-oxidative stability of epoxy resins by use of functional POSS additives: a spectroscopic, mechanical and morphological study. Polymer 53:5016–5036

Leu CM, Te Chang Y, Wei KH (2003) Polyimide-side-chain tethered polyhedral oligomeric silsesquioxane nanocomposites for low-dielectric film applications. Chem Mater 15:3721–3727

Wahab MA, Mya KY, He C (2008) Synthesis, morphology, and properties of hydroxyl terminated-POSS/Polyimide low-k nanocomposite films. J Polym Sci Pol Chem 46:5887–5896

Ye Y, Yen Y, Chen W, Cheng C, Chang F (2008) A simple approach toward low-dielectric polyimide nanocomposites: blending the polyimide precursor with a fluorinated polyhedral oligomeric silsesquioxane. J Polym Sci Pol Chem 46:6296–6304

Wang J, Ye Z, Joly H (2007) Synthesis and characterization of hyperbranched polyethylenes tethered with polyhedral oligomeric silsesquioxane (POSS) nanoparticles by chain walking ethylene copolymerization with acryloisobutyl-POSS. Macromolecules 40:6150–6163

Lee KM, Knight PT, Chung T, Mather PT (2008) Polycaprolactone-POSS chemical/physical double networks. Macromolecules 41:4730–4738

Frank KL, Exley SE, Thornell TL, Morgan SE, Wiggins JS (2012) Investigation of pre-reaction and cure temperature on multiscale dispersion in POSS/epoxy nanocomposites. Polymer 53:4643–4651

Tan BH, Hussain H, Leong YW, Lin TT, Tjiua WW, He C (2013) Tuning self-assembly of hybrid PLA-P(MA-POSS) block copolymers in solution via stereocomplexation. Polym Chem 4:1250–1259

Wang Z, Leng S, Wang Z, Li G, Hao Yu (2011) Nanostructured organic-inorganic copolymer networks based on polymethacrylate-functionalized octaphenylsilsesquioxane and methyl methacrylate: synthesis and characterization. Macromolecules 44:566–574

Huang J, Xiao Y, My KY, Liu X, He C, Dai J, Siow YP (2004) Thermomechanical properties of polyimide-epoxy nanocomposites from cubic silsesquioxane epoxides. J Mater Chem 14:2858–2863

Markovic E, Clarke S, Matisons J, Simon GP (2008) Synthesis of POSS-methyl methacrylate-based cross-linked hybrid materials. Macromolecules 41:1685–1692

Cardoen G, Coughlin EB (2004) Hemi-telechelic polystyrene-POSS copolymers as model systems for the study of well-defined inorganic/organic hybrid materials. Macromolecules 37:5123–5126

Kotal A, Si S, Paira TK, Mandal TK (2008) Synthesis of semitelechelic POSS-Polymethacrylate hybrids by thiol-mediated controlled radical polymerization with unusual thermal behaviors. J Polym Sci Pol Chem 46:1111–1123

Mather PT, Jeon HG, Romo-Uribe A (1999) Mechanical relaxation and microstructure of poly(norbornyl-POSS) copolymers. Macromolecules 32:1194–1203

Waddon AJ, Zheng L, Farris RJ, Bryan Coughlin E (2002) Nanostructured polyethylene-POSS copolymers: control of crystallization and aggregation. Nano Lett 10:1149–1155

Fina A, Tabuani D, Frache A, Camino G (2005) Polypropylene–polyhedral oligomeric silsesquioxanes (POSS) nanocomposites. Polymer 46:7855–7866

Li X, Xiaolong L (2007) Effect of annealing on the structure and properties of polyvinylidene fluoride hollow fiber by melt-spinning. J Appl Polym Sci 103:935–941

Goseki R, Hirai T, Ishida Y, Kakimoto M-a, Hayakawa T (2012) Rapid and reversible morphology control in thin films of poly(ethylene oxide)-block-POSS-containing poly(methacrylate). Polym J 44:658–664

Ni C, Ni G, Zhang L, Mi J, Yao B, Zhu C (2011) Syntheses of silsesquioxane (POSS)-based inorganic/organic hybrid and the application in reinforcement for an epoxy resin. J Colloid Interface Sci 362:94–99

Ni Y, Zheng S (2007) Nanostructured thermosets from epoxy resin and an organic-inorganic amphiphile. Macromolecules 40:7009–7018

Baldi F, Bignotti F, Ricco L, Monticelli O, Ricco T (2006) Mechanical and structural characterization of POSS modified polyamide. J Appl Polym Sci 100:3409–3414

Ding Y, Chen G, Song J, Gou Y, Shi J, Jin R, Li Q (2012) Properties and morphology of supertoughened polyamide 6 hybrid composites. J Appl Polym Sci 126:194–204

Madbouly SA, Otaigbe JU, Nanda AK, Wicks DA (2007) Rheological behavior of POSS/polyurethane-urea nanocomposite films prepared by homogeneous solution polymerization in aqueous dispersions. Macromolecules 40:4982–4991

Raftopoulos KN, Janowski B, Apekis L, Pissis P, Pielichowski K (2013) Direct and indirect effects of POSS on the molecular mobility of polyurethanes with varying segment Mw. Polymer 54:2745–2754

Chen Y, Kang E-T (2004) New approach to nanocomposites of polyimides containing polyhedral oligomeric silsesquioxane for dielectric applications. Mater Lett 58:3716–3719

Wright ME, Petteys BJ, Guenthner AJ, Fallis S, Yandek GR, Tomczak SJ, Minton TK, Brunsvold A (2006) Chemical modification of fluorinated polyimides: new thermally curing hybrid polymers with POSS. Macromolecules 39:4710–4718

Lee Y-J, Kuo S-W, Huang W-J, Lee H-Y, Chang F-C (2004) Miscibility, specific interactions, and self-assembly behavior of phenolic/polyhedral oligomeric silsesquioxane hybrids. J Polym Sci Polym Phys 42:1127–1136

Markovic E, Nguyen K, Clarke S, Constantopoulos K, Matisons J, Simon GP (2013) Synthesis of POSS-Polyurethane hybrids using octakis(m-isoprenyl-α,α’dimethylbenzylisocyanato dimethylsiloxy) octasilsesquioxane (Q8M8™I) as a crosslinking agent. J Polym Sci Pol Chem 51:5038–5045

Huitron-Rattinger E, Ishida K, Romo-Uribe A, Mather PT (2013) Thermally modulated nanostructure of poly(ε-caprolactone)-POSS multiblock thermoplastic polyurethanes. Polymer 54:3350–3362

Turri S, Levi M (2005) Structure, dynamic properties, and surface behavior of nanostructured ionomeric polyurethanes from reactive polyhedral oligomeric silsesquioxanes. Macromolecules 38:5569–5574

Knight PT, Lee KM, Qin H, Mather PT (2008) Biodegradable thermoplastic polyurethanes incorporating polyhedral oligosilsesquioxane. Biomacromolecules 9:2458–2467

Janowski B, Pielichowski K (2008) Thermo(oxidative) stability of novel polyurethane/POSS nanohybrid elastomers. Thermochim Acta 478:51–53

Seino M, Hayakawa T, Ishida Y, Kakimoto M-a (2006) Hydrosilylation polymerization of double-decker-shaped silsesquioxane having hydrosilane with diynes. Macromolecules 39:3473–3475

Petrović ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48:109–155

Liu H, Zheng S (2005) Polyurethane networks nanoreinforced by polyhedral oligomeric silsesquioxane. Macromol Rapid Commun 26:196–200

Wang W, Guo Y-l, Otaigbe JU (2009) The synthesis, characterization and biocompatibility of poly(ester urethane)/polyhedral oligomeric silesquioxane nanocomposites. Polym 50:5749–5757

Morent R, De Geyter N, Van Vlierberghe S, Beaurain A, Dubruel P, Payen E (2011) Influence of operating parameters on plasma polymerization of acrylic acid in a mesh-to-plate dielectric barrier discharge. Prog Org Coat 70:336–341

Ruijun G, Konar S, Sain M (2012) Preparation and characterization of sustainable polyurethane foams from soybean oils. J Am Oil Chem Soc 89:2103–2111

Bandyopadhyay-Ghosh S, Ghosh SB, Sain M (2010) Synthesis of soy-polyol by two step continuous route and development of soy-based polyurethane foam. J Polym Environ 18:437–442

Vaia RA, Maguire JF (2007) Polymer Nanocomposites with prescribed morphology: going beyond nanoparticle-filled polymers. Chem Mater 19:2736–2751

Sanchez C, Julián B, Belleville P, Popall M (2005) Applications of hybrid organic-inorganic nanocomposites. J Mater Chem 15:3559–3592

Strachota A, Kroutilová I, Kovárová J, Matějka L (2004) Epoxy networks reinforced with polyhedral oligomeric silsesquioxanes (POSS). Thermomechanical properties. Macromolecules 37:9457–9464

Liu Y, Ni Y, Zheng S (2006) Polyurethane networks modified with octa(propylglycidyl ether) polyhedral oligomeric silsesquioxane. Macromol Chem Phys 207:1842–1851

Acknowledgements

This work was supported by research Grants from the National Key Technology Research and Development Program (2012BAD32B03-4) and the Cooperative Innovation Foundation of Industry, Academy and Research Institutes (BY2013015-10) in Jiangsu Province of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, J., Jiang, P., Li, X. et al. Synthesis and characterization of sustainable polyurethane based on epoxy soybean oil and modified by double-decker silsesquioxane. J Mater Sci 51, 2443–2452 (2016). https://doi.org/10.1007/s10853-015-9557-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9557-0